General Products - ALP Industries Inc.

General Products - ALP Industries Inc.

General Products - ALP Industries Inc.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

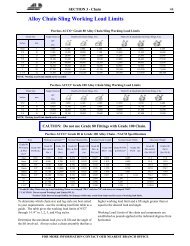

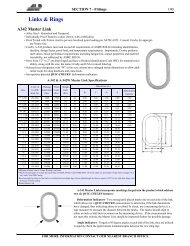

163 SECTION 8 - BlocksTackle Block ReevingTHE REEVING OF TACKLE BLOCKSIn reeving tackle blocks, there are many methods. Themethod discussed below is referred to as “Right Angle” reeving.Please consult your rigging manual for other methods ofreeving.RIGHT ANGLE REEVINGIn reeving a pair of tackle blocks, one of which has morethan two sheaves, the hoisting rope should lead from one ofthe center sheaves of the upper block to prevent toppling andavoid injury to the rope. The two blocks should be placed sothat the sheaves in the upper block are at right angles to thosein the lower one, as shown in the following illustrations.Start reeving with the becket, or dead end, of the rope. Usea shackle block as the upper one of a pair and a hookblock as the lower one as seen below.Sheaves in a set of blocks revolve at different rates ofspeed. Those nearest the lead line, revolve at the highest rateof speed and wear out more rapidly.All sheaves should be kept well lubricated when in operationto reduce friction and wear.Ratio A BronzeBushed SheavesRatio B Anti-Friction BearingNumber of Partsof Line.96 .98 11.87 1.94 22.75 2.88 33.59 3.81 44.39 4.71 55.16 5.60 65.90 6.47 76.60 7.32 87.27 8.16 97.91 8.98 108.52 9.79 119.11 10.6 129.68 11.4 1310.2 12.1 1410.7 12.9 1511.2 13.6 1611.7 14.3 1712.2 15.0 1812.6 15.7 1913.0 16.4 20Ratio A or B =Total Load to be LiftedSingle Line Pull (lbs.)After calculating Ratio A or B, consult the table to determinenumber of parts of line.Examples:To find the number of parts of line needed when weight loadand single line pull are known and using Bronze BushedSheaves.72,180 lbs. (load to be lifted) = 9.02 (Ratio A)8,000 lbs. (single line pull)Refer to ratio 9.02 in table or number nearest to it, then check columnunder heading “Number of Parts of Line”... 12 parts of line tobe used for this load.-----------------------------------------------------------------------------To find the single line pull needed when weight of load andnumber of parts of lines are known and using Anti-FrictionBearing Sheaves.68,000 lbs. (load to be lifted) = 9,290 lbs.7.32 (ratio B of 8 part line) (Single Line Pull)HOW TO FIGURE LINE PARTSSheaves in a system of blocks rotate at different rates ofspeed, and have different loads. When raising and lowering,the line tension is not equal throughout the system. To helpfigure the number of parts of line to be used for a given load,or the line pull required for a given load, the following ratiotable is provided with examples of how to use it.:9,290 lbs. single line pull required to lift this load on 8 parts of aline.-----------------------------------------------------------------------------To find the lift capacity when the parts of line and single linepull are known, and using Anti-Friction Bearing Sheaves.10,000 lbs. (Single Line Pull)x 4.71 (Ratio B of 5 parts of line)=47,100 lbs. (Lift Capacity)10,000 lbs. single line pull with 5 parts of line will accommodate47,100 lbs. lift capacity.FOR MORE INFORMATION CONTACT OUR NEAREST BRANCH OFFICE