Synchronous Motors

Synchronous Motors

Synchronous Motors

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

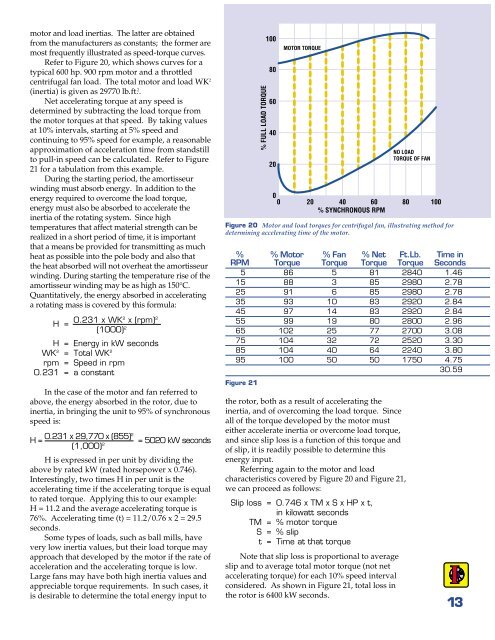

motor and load inertias. The latter are obtainedfrom the manufacturers as constants; the former aremost frequently illustrated as speed-torque curves.Refer to Figure 20, which shows curves for atypical 600 hp. 900 rpm motor and a throttledcentrifugal fan load. The total motor and load WK 2(inertia) is given as 29770 lb.ft. 2 .Net accelerating torque at any speed isdetermined by subtracting the load torque fromthe motor torques at that speed. By taking valuesat 10% intervals, starting at 5% speed andcontinuing to 95% speed for example, a reasonableapproximation of acceleration time from standstillto pull-in speed can be calculated. Refer to Figure21 for a tabulation from this example.During the starting period, the amortisseurwinding must absorb energy. In addition to theenergy required to overcome the load torque,energy must also be absorbed to accelerate theinertia of the rotating system. Since hightemperatures that affect material strength can berealized in a short period of time, it is importantthat a means be provided for transmitting as muchheat as possible into the pole body and also thatthe heat absorbed will not overheat the amortisseurwinding. During starting the temperature rise of theamortisseur winding may be as high as 150°C.Quantitatively, the energy absorbed in acceleratinga rotating mass is covered by this formula:H = 0.231 x WK2 x (rpm) 2(1000) 2H = Energy in kW secondsWK 2 = Total WK 2rpm = Speed in rpm0.231 = a constantIn the case of the motor and fan referred toabove, the energy absorbed in the rotor, due toinertia, in bringing the unit to 95% of synchronousspeed is:H =0.231 x 29,770 x (855)2= 5020 kW seconds(1,000) 2H is expressed in per unit by dividing theabove by rated kW (rated horsepower x 0.746).Interestingly, two times H in per unit is theaccelerating time if the accelerating torque is equalto rated torque. Applying this to our example:H = 11.2 and the average accelerating torque is76%. Accelerating time (t) = 11.2/0.76 x 2 = 29.5seconds.Some types of loads, such as ball mills, havevery low inertia values, but their load torque mayapproach that developed by the motor if the rate ofacceleration and the accelerating torque is low.Large fans may have both high inertia values andappreciable torque requirements. In such cases, itis desirable to determine the total energy input to% FULL LOAD TORQUE10080604020MOTOR TORQUE00 20 40 60 80 100% SYNCHRONOUS RPMthe rotor, both as a result of accelerating theinertia, and of overcoming the load torque. Sinceall of the torque developed by the motor musteither accelerate inertia or overcome load torque,and since slip loss is a function of this torque andof slip, it is readily possible to determine thisenergy input.Referring again to the motor and loadcharacteristics covered by Figure 20 and Figure 21,we can proceed as follows:Slip loss = 0.746 x TM x S x HP x t,in kilowatt secondsTM = % motor torqueS = % slipt = Time at that torqueNote that slip loss is proportional to averageslip and to average total motor torque (not netaccelerating torque) for each 10% speed intervalconsidered. As shown in Figure 21, total loss inthe rotor is 6400 kW seconds.NO LOADTORQUE OF FANFigure 20 Motor and load torques for centrifugal fan, illustrating method fordetermining accelerating time of the motor.% % Motor % Fan % Net Ft.Lb. Time inRPM Torque Torque Torque Torque Seconds5 86 5 81 2840 1.4615 88 3 85 2980 2.7825 91 6 85 2980 2.7835 93 10 83 2920 2.8445 97 14 83 2920 2.8455 99 19 80 2800 2.9665 102 25 77 2700 3.0875 104 32 72 2520 3.3085 104 40 64 2240 3.8095 100 50 50 1750 4.7530.59Figure 2113