Synchronous Motors

Synchronous Motors

Synchronous Motors

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

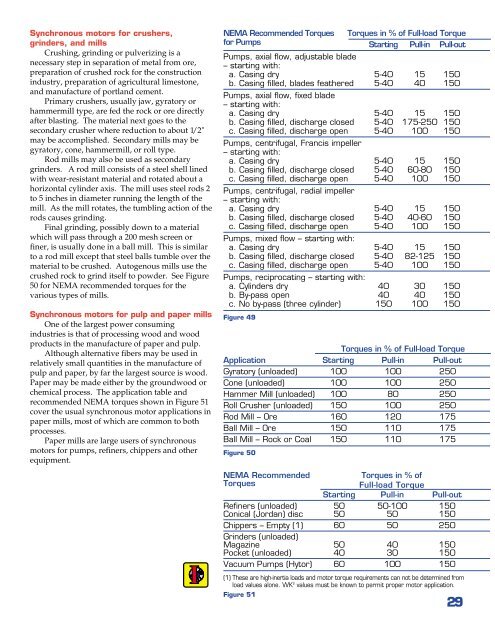

<strong>Synchronous</strong> motors for crushers,grinders, and millsCrushing, grinding or pulverizing is anecessary step in separation of metal from ore,preparation of crushed rock for the constructionindustry, preparation of agricultural limestone,and manufacture of portland cement.Primary crushers, usually jaw, gyratory orhammermill type, are fed the rock or ore directlyafter blasting. The material next goes to thesecondary crusher where reduction to about 1/2"may be accomplished. Secondary mills may begyratory, cone, hammermill, or roll type.Rod mills may also be used as secondarygrinders. A rod mill consists of a steel shell linedwith wear-resistant material and rotated about ahorizontal cylinder axis. The mill uses steel rods 2to 5 inches in diameter running the length of themill. As the mill rotates, the tumbling action of therods causes grinding.Final grinding, possibly down to a materialwhich will pass through a 200 mesh screen orfiner, is usually done in a ball mill. This is similarto a rod mill except that steel balls tumble over thematerial to be crushed. Autogenous mills use thecrushed rock to grind itself to powder. See Figure50 for NEMA recommended torques for thevarious types of mills.<strong>Synchronous</strong> motors for pulp and paper millsOne of the largest power consumingindustries is that of processing wood and woodproducts in the manufacture of paper and pulp.Although alternative fibers may be used inrelatively small quantities in the manufacture ofpulp and paper, by far the largest source is wood.Paper may be made either by the groundwood orchemical process. The application table andrecommended NEMA torques shown in Figure 51cover the usual synchronous motor applications inpaper mills, most of which are common to bothprocesses.Paper mills are large users of synchronousmotors for pumps, refiners, chippers and otherequipment.NEMA Recommended Torques Torques in % of Full-load Torquefor Pumps Starting Pull-in Pull-outPumps, axial flow, adjustable blade– starting with:a. Casing dry 5-40 15 150b. Casing filled, blades feathered 5-40 40 150Pumps, axial flow, fixed blade– starting with:a. Casing dry 5-40 15 150b. Casing filled, discharge closed 5-40 175-250 150c. Casing filled, discharge open 5-40 100 150Pumps, centrifugal, Francis impeller– starting with:a. Casing dry 5-40 15 150b. Casing filled, discharge closed 5-40 60-80 150c. Casing filled, discharge open 5-40 100 150Pumps, centrifugal, radial impeller– starting with:a. Casing dry 5-40 15 150b. Casing filled, discharge closed 5-40 40-60 150c. Casing filled, discharge open 5-40 100 150Pumps, mixed flow – starting with:a. Casing dry 5-40 15 150b. Casing filled, discharge closed 5-40 82-125 150c. Casing filled, discharge open 5-40 100 150Pumps, reciprocating – starting with:a. Cylinders dry 40 30 150b. By-pass open 40 40 150c. No by-pass (three cylinder) 150 100 150Figure 49Torques in % of Full-load TorqueApplication Starting Pull-in Pull-outGyratory (unloaded) 100 100 250Cone (unloaded) 100 100 250Hammer Mill (unloaded) 100 80 250Roll Crusher (unloaded) 150 100 250Rod Mill – Ore 160 120 175Ball Mill – Ore 150 110 175Ball Mill – Rock or Coal 150 110 175Figure 50NEMA RecommendedTorques in % ofTorquesFull-load TorqueStarting Pull-in Pull-outRefiners (unloaded) 50 50-100 150Conical (Jordan) disc 50 50 150Chippers – Empty (1) 60 50 250Grinders (unloaded)MagazinePocket (unloaded)50404030150150Vacuum Pumps (Hytor) 60 100 150(1) These are high-inertia loads and motor torque requirements can not be determined fromload values alone. WK 2 values must be known to permit proper motor application.Figure 5129