Synchronous Motors

Synchronous Motors

Synchronous Motors

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

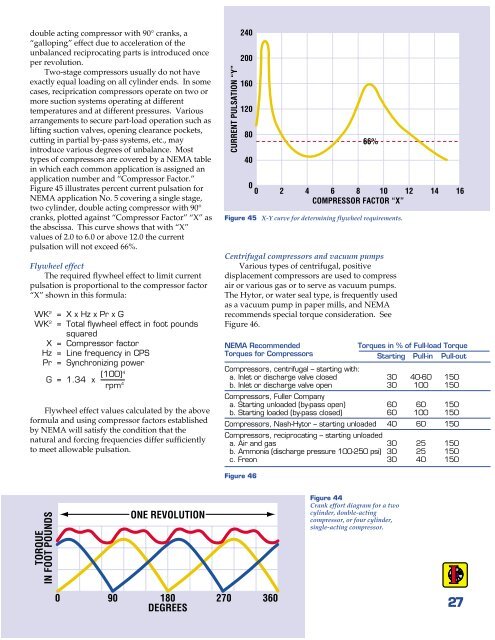

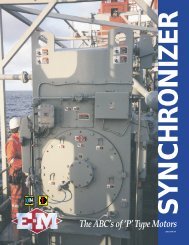

double acting compressor with 90° cranks, a“galloping” effect due to acceleration of theunbalanced reciprocating parts is introduced onceper revolution.Two-stage compressors usually do not haveexactly equal loading on all cylinder ends. In somecases, reciprication compressors operate on two ormore suction systems operating at differenttemperatures and at different pressures. Variousarrangements to secure part-load operation such aslifting suction valves, opening clearance pockets,cutting in partial by-pass systems, etc., mayintroduce various degrees of unbalance. Mosttypes of compressors are covered by a NEMA tablein which each common application is assigned anapplication number and “Compressor Factor.”Figure 45 illustrates percent current pulsation forNEMA application No. 5 covering a single stage,two cylinder, double acting compressor with 90°cranks, plotted against “Compressor Factor” “X” asthe abscissa. This curve shows that with “X”values of 2.0 to 6.0 or above 12.0 the currentpulsation will not exceed 66%.Flywheel effectThe required flywheel effect to limit currentpulsation is proportional to the compressor factor“X” shown in this formula:WK 2 = X x Hz x Pr x GWK 2 = Total flywheel effect in foot poundssquaredX = Compressor factorHz = Line frequency in CPSPr = Synchronizing powerG = 1.34 x (100)4rpm 4Flywheel effect values calculated by the aboveformula and using compressor factors establishedby NEMA will satisfy the condition that thenatural and forcing frequencies differ sufficientlyto meet allowable pulsation.CURRENT PULSATION “Y”24020016012080400066%2 4 6 8 10 12 14 16COMPRESSOR FACTOR “X”Figure 45 X-Y curve for determining flywheel requirements.Centrifugal compressors and vacuum pumpsVarious types of centrifugal, positivedisplacement compressors are used to compressair or various gas or to serve as vacuum pumps.The Hytor, or water seal type, is frequently usedas a vacuum pump in paper mills, and NEMArecommends special torque consideration. SeeFigure 46.NEMA RecommendedTorques in % of Full-load TorqueTorques for Compressors Starting Pull-in Pull-outCompressors, centrifugal – starting with:a. Inlet or discharge valve closed 30 40-60 150b. Inlet or discharge valve open 30 100 150Compressors, Fuller Companya. Starting unloaded (by-pass open) 60 60 150b. Starting loaded (by-pass closed) 60 100 150Compressors, Nash-Hytor – starting unloaded 40 60 150Compressors, reciprocating – starting unloadeda. Air and gas 30 25 150b. Ammonia (discharge pressure 100-250 psi) 30 25 150c. Freon 30 40 150Figure 46TORQUEIN FOOT POUNDSONE REVOLUTIONFigure 44Crank effort diagram for a twocylinder, double-actingcompressor, or four cylinder,single-acting compressor.0 90 180 270 360DEGREES27