Synchronous Motors

Synchronous Motors

Synchronous Motors

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

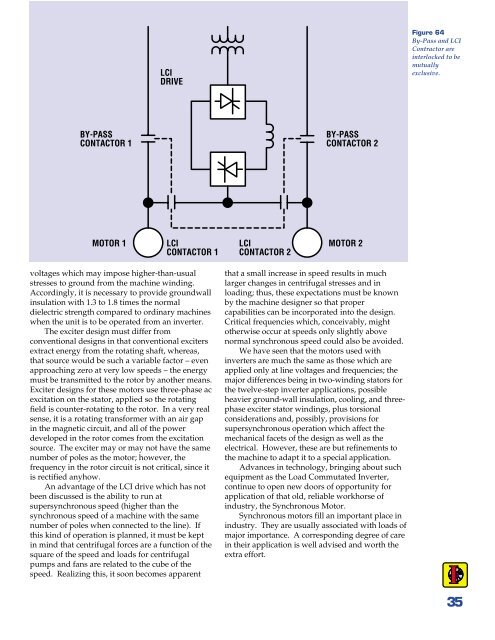

LCIDRIVEFigure 64By-Pass and LCIContractor areinterlocked to bemutuallyexclusive.BY-PASSCONTACTOR 1BY-PASSCONTACTOR 2MOTOR 1LCICONTACTOR 1LCICONTACTOR 2MOTOR 2voltages which may impose higher-than-usualstresses to ground from the machine winding.Accordingly, it is necessary to provide groundwallinsulation with 1.3 to 1.8 times the normaldielectric strength compared to ordinary machineswhen the unit is to be operated from an inverter.The exciter design must differ fromconventional designs in that conventional excitersextract energy from the rotating shaft, whereas,that source would be such a variable factor – evenapproaching zero at very low speeds – the energymust be transmitted to the rotor by another means.Exciter designs for these motors use three-phase acexcitation on the stator, applied so the rotatingfield is counter-rotating to the rotor. In a very realsense, it is a rotating transformer with an air gapin the magnetic circuit, and all of the powerdeveloped in the rotor comes from the excitationsource. The exciter may or may not have the samenumber of poles as the motor; however, thefrequency in the rotor circuit is not critical, since itis rectified anyhow.An advantage of the LCI drive which has notbeen discussed is the ability to run atsupersynchronous speed (higher than thesynchronous speed of a machine with the samenumber of poles when connected to the line). Ifthis kind of operation is planned, it must be keptin mind that centrifugal forces are a function of thesquare of the speed and loads for centrifugalpumps and fans are related to the cube of thespeed. Realizing this, it soon becomes apparentthat a small increase in speed results in muchlarger changes in centrifugal stresses and inloading; thus, these expectations must be knownby the machine designer so that propercapabilities can be incorporated into the design.Critical frequencies which, conceivably, mightotherwise occur at speeds only slightly abovenormal synchronous speed could also be avoided.We have seen that the motors used withinverters are much the same as those which areapplied only at line voltages and frequencies; themajor differences being in two-winding stators forthe twelve-step inverter applications, possibleheavier ground-wall insulation, cooling, and threephaseexciter stator windings, plus torsionalconsiderations and, possibly, provisions forsupersynchronous operation which affect themechanical facets of the design as well as theelectrical. However, these are but refinements tothe machine to adapt it to a special application.Advances in technology, bringing about suchequipment as the Load Commutated Inverter,continue to open new doors of opportunity forapplication of that old, reliable workhorse ofindustry, the <strong>Synchronous</strong> Motor.<strong>Synchronous</strong> motors fill an important place inindustry. They are usually associated with loads ofmajor importance. A corresponding degree of carein their application is well advised and worth theextra effort.35