to download PDF version - Toyota

to download PDF version - Toyota

to download PDF version - Toyota

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

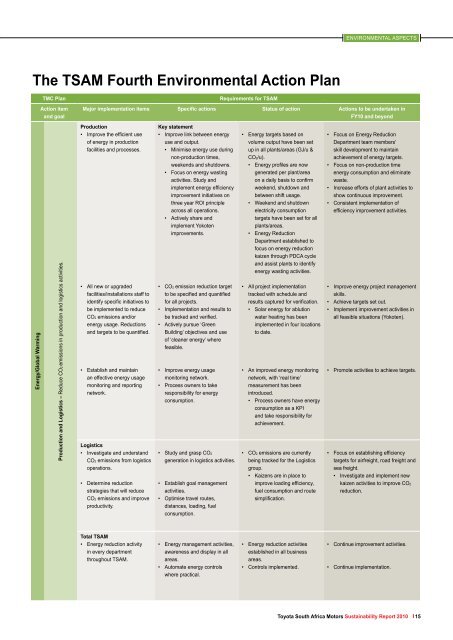

The TSAM Fourth Environmental Action Plan<br />

Energy/Global Warming<br />

TMC Plan Requirements for TSAM<br />

Action item<br />

and goal<br />

Production and Logistics – Reduce CO2 emissions in production and logistics activities.<br />

ENVIRONMENTAL ASPECTS<br />

Major implementation items Specific actions Status of action Actions <strong>to</strong> be undertaken in<br />

FY10 and beyond<br />

Production<br />

• Improve the efficient use<br />

of energy in production<br />

facilities and processes.<br />

• All new or upgraded<br />

facilities/installations staff <strong>to</strong><br />

identify specific initiatives <strong>to</strong><br />

be implemented <strong>to</strong> reduce<br />

CO2 emissions and/or<br />

energy usage. Reductions<br />

and targets <strong>to</strong> be quantified.<br />

• Establish and maintain<br />

an effective energy usage<br />

moni<strong>to</strong>ring and reporting<br />

network.<br />

Logistics<br />

• Investigate and understand<br />

CO2 emissions from logistics<br />

operations.<br />

• Determine reduction<br />

strategies that will reduce<br />

CO2 emissions and improve<br />

productivity.<br />

Total TSAM<br />

• Energy reduction activity<br />

in every department<br />

throughout TSAM.<br />

Key statement<br />

• Improve link between energy<br />

use and output.<br />

• Minimise energy use during<br />

non-production times,<br />

weekends and shutdowns.<br />

• Focus on energy wasting<br />

activities. Study and<br />

implement energy efficiency<br />

improvement initiatives on<br />

three year ROI principle<br />

across all operations.<br />

• Actively share and<br />

implement Yokoten<br />

improvements.<br />

• CO2<br />

emission reduction target<br />

<strong>to</strong> be specified and quantified<br />

for all projects.<br />

• Implementation and results <strong>to</strong><br />

be tracked and verified.<br />

• Actively pursue ‘Green<br />

Building’ objectives and use<br />

of ‘cleaner energy’ where<br />

feasible.<br />

• Improve energy usage<br />

moni<strong>to</strong>ring network.<br />

• Process owners <strong>to</strong> take<br />

responsibility for energy<br />

consumption.<br />

• Study and grasp CO2<br />

generation in logistics activities.<br />

• Establish goal management<br />

activities.<br />

• Optimise travel routes,<br />

distances, loading, fuel<br />

consumption.<br />

• Energy management activities,<br />

awareness and display in all<br />

areas.<br />

• Au<strong>to</strong>mate energy controls<br />

where practical.<br />

• Energy targets based on<br />

volume output have been set<br />

up in all plants/areas (GJ/u &<br />

CO2/u).<br />

• Energy profiles are now<br />

generated per plant/area<br />

on a daily basis <strong>to</strong> confirm<br />

weekend, shutdown and<br />

between shift usage.<br />

• Weekend and shutdown<br />

electricity consumption<br />

targets have been set for all<br />

plants/areas.<br />

• Energy Reduction<br />

Department established <strong>to</strong><br />

focus on energy reduction<br />

kaizen through PDCA cycle<br />

and assist plants <strong>to</strong> identify<br />

energy wasting activities.<br />

• All project implementation<br />

tracked with schedule and<br />

results captured for verification.<br />

• Solar energy for ablution<br />

water heating has been<br />

implemented in four locations<br />

<strong>to</strong> date.<br />

• An improved energy moni<strong>to</strong>ring<br />

network, with ‘real time’<br />

measurement has been<br />

introduced.<br />

• Process owners have energy<br />

consumption as a KPI<br />

and take responsibility for<br />

achievement.<br />

• CO2<br />

emissions are currently<br />

being tracked for the Logistics<br />

group.<br />

• Kaizens are in place <strong>to</strong><br />

improve loading efficiency,<br />

fuel consumption and route<br />

simplification.<br />

• Energy reduction activities<br />

established in all business<br />

areas.<br />

• Controls implemented.<br />

• Focus on Energy Reduction<br />

Department team members’<br />

skill development <strong>to</strong> maintain<br />

achievement of energy targets.<br />

• Focus on non-production time<br />

energy consumption and eliminate<br />

waste.<br />

• Increase efforts of plant activities <strong>to</strong><br />

show continuous improvement.<br />

• Consistent implementation of<br />

efficiency improvement activities.<br />

• Improve energy project management<br />

skills.<br />

• Achieve targets set out.<br />

• Implement improvement activities in<br />

all feasible situations (Yokoten).<br />

•<br />

Promote activities <strong>to</strong> achieve targets.<br />

• Focus on establishing efficiency<br />

targets for airfreight, road freight and<br />

sea freight.<br />

• Investigate and implement new<br />

kaizen activities <strong>to</strong> improve CO2<br />

reduction.<br />

•<br />

•<br />

Continue improvement activities.<br />

Continue implementation.<br />

<strong>Toyota</strong> South Africa Mo<strong>to</strong>rs Sustainability Report 2010 15