WESTERBEKE GASOLINE GENERATOR

WESTERBEKE GASOLINE GENERATOR

WESTERBEKE GASOLINE GENERATOR

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

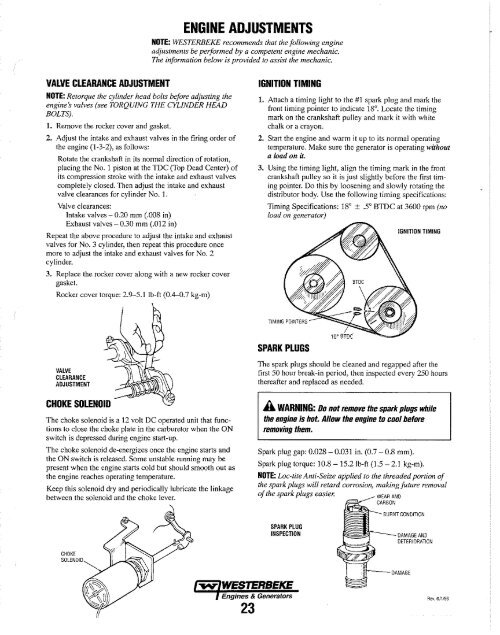

ENGINE ADJUSTMENTSNOTE: <strong>WESTERBEKE</strong> recommends that the following engineadjustments be performed by a competent engine mechanic.The information below is provided to assist the mechanic.VALVE CLEARANCE ADJUSTMENTNOTE: Retorque the cylinder head bolts before adjusting theengine's valves (see TORQUING THE CYLINDER HEADBOLTS).1. Remove the rocker cover and gasket.2. Adjust the intake and exhaust valves in the firing order ofthe engine (1-3-2), as follows:Rotate the crankshaft in its nonnaI direction of rotation,placing the No. I piston at the IDC (Top Dead Center) ofits compression stroke with the intake and exhaust valvescompletely closed. Then adjust the intake and exhaustvalve clearances for cylinder No. ].Valve clearances:Intake valves - 0.20 mm (.008 in)Exhaust valves - 0.30 mm (.012 in)Repeat the above procedure to adjust the intake and exhaustvalves for No.3 cylinder, then repeat this procedure oncemore to adjust the intake and exhaust valves for No.2cylinder.3. Replace the rocker cover along with a new rocker covergasket.Rocker cover torque: 2.9-5.1 Ib-ft (0.4-0.7 kg-m)IGNITION TIMING1. Attach a timing light to the #1 spark plug and mark thefront timing pointer to indicate 18°. Locate the timingmark on the crankshaft pulley and mark it with whitechalk or a crayon.2. Start the engine and warm it up to its normal operatingtemperature. Make sure the generator is operating withouta load on it.3. Using the timing light, align the timing mark in the frontcrankshaft pulley so it is just slightly before the first timingpointer. Do this by loosening and slowly rotating thedistributor body. Use the following timing specifications:Timing Specifications: 18° ± .so BIDC at 3600 rpm (noload on generator)tGNITION TIMINGSPARK PLUGSVALVECLEARANCEADJUSTMENTCHOKE SOLENOIDThe choke solenoid is a 12 volt DC operated unit that functionsto close the choke plate in the carburetor when the ONswitch is depressed during engine start-up.The choke solenoid de-energizes once the engine starts andthe ON switch is released. Some unstable running may bepresent when the engine starts cold but should smooth out asthe engine reaches operating temperature.Keep this solenoid dry and periodically lubricate the linkagebetween the solenoid and the choke lever.The spark plugs should be cleaned and rcgapped after thefirst 50 hour break-in period, then inspected every 250 hoursthereafter and replaced as needed.A WARNING: Do not remove the spark plugs whilethe engine is hot. Allow the engine to cool beforeremoving them.Spark plug gap: 0.028 - 0.031 in. (0.7 - 0.8 mm).Spark plug torque: 10.8 -15.2lb-ft (1.5 - 2.1 kg-m).NOTE: Loc-tite Anti-Seize applied to the threaded portion ofthe spark plugs will retard corrosion, making future removalof the spark plugs easier.WEAR ANDCARBONBURNT CONDITIONSPARK PLUGINSPECTIONI---D""GE ANDDETERIORATIONCHOKESOLENOID~ <strong>WESTERBEKE</strong>Engines & Generators Rev. 6(119823