3. PPECB Annual Report 2009-2010

3. PPECB Annual Report 2009-2010

3. PPECB Annual Report 2009-2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

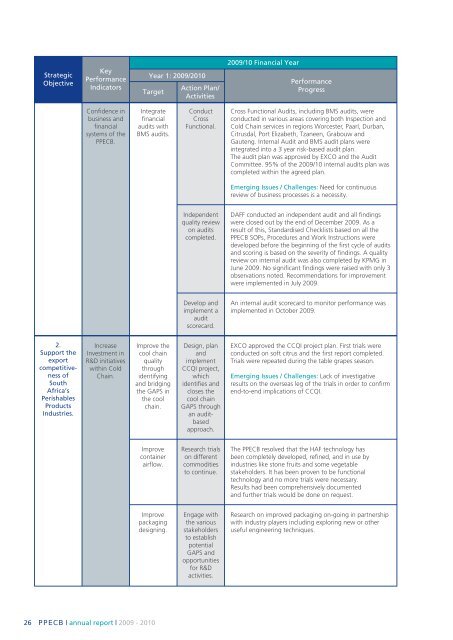

StrategicObjectiveKeyPerformanceIndicatorsYear 1: <strong>2009</strong>/<strong>2010</strong>TargetAction Plan/Activities<strong>2009</strong>/10 Financial YearPerformanceProgressConfidence inbusiness andfinancialsystems of the<strong>PPECB</strong>.Integratefinancialaudits withBMS audits.ConductCrossFunctional.Cross Functional Audits, including BMS audits, wereconducted in various areas covering both Inspection andCold Chain services in regions Worcester, Paarl, Durban,Citrusdal, Port Elizabeth, Tzaneen, Grabouw andGauteng. Internal Audit and BMS audit plans wereintegrated into a 3 year risk-based audit plan.The audit plan was approved by EXCO and the AuditCommittee. 95% of the <strong>2009</strong>/10 internal audits plan wascompleted within the agreed plan.Emerging Issues / Challenges: Need for continuousreview of business processes is a necessity.Independentquality reviewon auditscompleted.DAFF conducted an independent audit and all findingswere closed out by the end of December <strong>2009</strong>. As aresult of this, Standardised Checklists based on all the<strong>PPECB</strong> SOPs, Procedures and Work Instructions weredeveloped before the beginning of the first cycle of auditsand scoring is based on the severity of findings. A qualityreview on internal audit was also completed by KPMG inJune <strong>2009</strong>. No significant findings were raised with only 3observations noted. Recommendations for improvementwere implemented in July <strong>2009</strong>.Develop andimplement aauditscorecard.An internal audit scorecard to monitor performance wasimplemented in October <strong>2009</strong>.2.Support theexportcompetitivenessofSouthAfrica’sPerishablesProductsIndustries.IncreaseInvestment inR&D initiativeswithin ColdChain.Improve thecool chainqualitythroughidentifyingand bridgingthe GAPS inthe coolchain.Design, planandimplementCCQI project,whichidentifies andcloses thecool chainGAPS throughan auditbasedapproach.EXCO approved the CCQI project plan. First trials wereconducted on soft citrus and the first report completed.Trials were repeated during the table grapes season.Emerging Issues / Challenges: Lack of investigativeresults on the overseas leg of the trials in order to confirmend-to-end implications of CCQI.Improvecontainerairflow.Research trialson differentcommoditiesto continue.The <strong>PPECB</strong> resolved that the HAF technology hasbeen completely developed, refined, and in use byindustries like stone fruits and some vegetablestakeholders. It has been proven to be functionaltechnology and no more trials were necessary.Results had been comprehensively documentedand further trials would be done on request.Improvepackagingdesigning.Engage withthe variousstakeholdersto establishpotentialGAPS andopportunitiesfor R&Dactivities.Research on improved packaging on-going in partnershipwith industry players including exploring new or otheruseful engineering techniques.26<strong>PPECB</strong> | annual report | <strong>2009</strong> - <strong>2010</strong>

![National Research Foundation Annual Report 2008 / 2009 [Part 2]](https://img.yumpu.com/49774036/1/177x260/national-research-foundation-annual-report-2008-2009-part-2.jpg?quality=85)