3. PPECB Annual Report 2009-2010

3. PPECB Annual Report 2009-2010

3. PPECB Annual Report 2009-2010

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

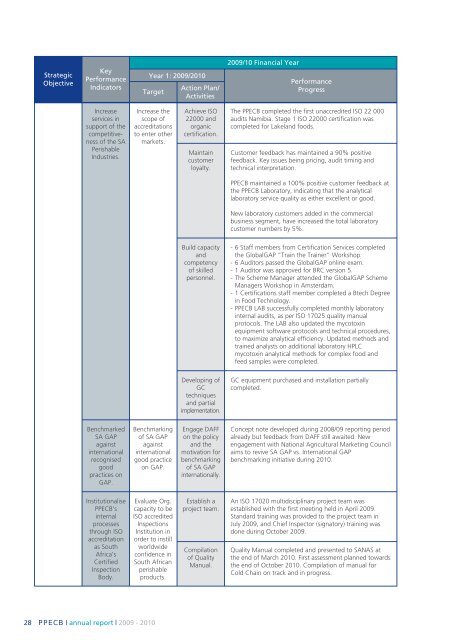

StrategicObjectiveKeyPerformanceIndicatorsYear 1: <strong>2009</strong>/<strong>2010</strong>TargetAction Plan/Activities<strong>2009</strong>/10 Financial YearPerformanceProgressIncreaseservices insupport of thecompetitivenessof the SAPerishableIndustries.Increase thescope ofaccreditationsto enter othermarkets.Achieve ISO22000 andorganiccertification.Maintaincustomerloyalty.The <strong>PPECB</strong> completed the first unaccredited ISO 22 000audits Namibia. Stage 1 ISO 22000 certification wascompleted for Lakeland foods.Customer feedback has maintained a 90% positivefeedback. Key issues being pricing, audit timing andtechnical interpretation.<strong>PPECB</strong> maintained a 100% positive customer feedback atthe <strong>PPECB</strong> Laboratory, indicating that the analyticallaboratory service quality as either excellent or good.New laboratory customers added in the commercialbusiness segment, have increased the total laboratorycustomer numbers by 5%.Build capacityandcompetencyof skilledpersonnel.- 6 Staff members from Certification Services completedthe GlobalGAP “Train the Trainer” Workshop.- 6 Auditors passed the GlobalGAP online exam.- 1 Auditor was approved for BRC version 5.- The Scheme Manager attended the GlobalGAP SchemeManagers Workshop in Amsterdam.- 1 Certifications staff member completed a Btech Degreein Food Technology.- <strong>PPECB</strong> LAB successfully completed monthly laboratoryinternal audits, as per ISO 17025 quality manualprotocols. The LAB also updated the mycotoxinequipment software protocols and technical procedures,to maximize analytical efficiency. Updated methods andtrained analysts on additional laboratory HPLCmycotoxin analytical methods for complex food andfeed samples were completed.Developing ofGCtechniquesand partialimplementation.GC equipment purchased and installation partiallycompleted.BenchmarkedSA GAPagainstinternationalrecognisedgoodpractices onGAP.Benchmarkingof SA GAPagainstinternationalgood practiceon GAP.Engage DAFFon the policyand themotivation forbenchmarkingof SA GAPinternationally.Concept note developed during 2008/09 reporting periodalready but feedback from DAFF still awaited. Newengagement with National Agricultural Marketing Councilaims to revive SA GAP vs. International GAPbenchmarking initiative during <strong>2010</strong>.Institutionalise<strong>PPECB</strong>’sinternalprocessesthrough ISOaccreditationas SouthAfrica’sCertifiedInspectionBody.Evaluate Org.capacity to beISO accreditedInspectionsInstitution inorder to instillworldwideconfidence inSouth Africanperishableproducts.Establish aproject team.Compilationof QualityManual.An ISO 17020 multidisciplinary project team wasestablished with the first meeting held in April <strong>2009</strong>.Standard training was provided to the project team inJuly <strong>2009</strong>, and Chief Inspector (signatory) training wasdone during October <strong>2009</strong>.Quality Manual completed and presented to SANAS atthe end of March <strong>2010</strong>. First assessment planned towardsthe end of October <strong>2010</strong>. Compilation of manual forCold Chain on track and in progress.28<strong>PPECB</strong> | annual report | <strong>2009</strong> - <strong>2010</strong>

![National Research Foundation Annual Report 2008 / 2009 [Part 2]](https://img.yumpu.com/49774036/1/177x260/national-research-foundation-annual-report-2008-2009-part-2.jpg?quality=85)