PIC Design - RBC Bearings

PIC Design - RBC Bearings

PIC Design - RBC Bearings

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

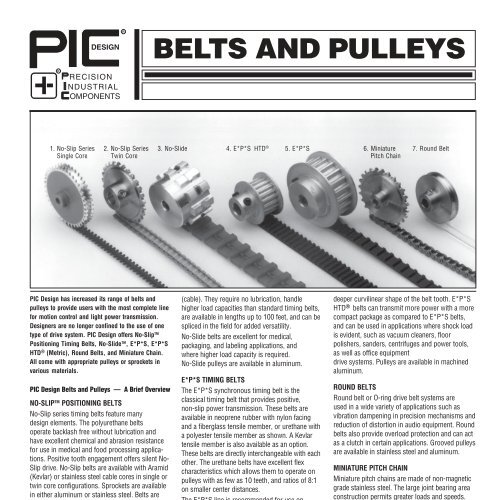

DESIGNRBELTS AND PULLEYSRRECISIONNDUSTRIALOMPONENTS1. No-Slip Series 2. No-Slip Series 3. No-Slide 4. E*P*S HTD ® 5. E*P*S 6. Miniature 7. Round Belt1. Single Core 2. Twin Core Pitch Chain<strong>PIC</strong> <strong>Design</strong> has increased its range of belts andpulleys to provide users with the most complete linefor motion control and light power transmission.<strong>Design</strong>ers are no longer confined to the use of onetype of drive system. <strong>PIC</strong> <strong>Design</strong> offers No-Slip TMPositioning Timing Belts, No-Slide TM , E*P*S, E*P*SHTD ® (Metric), Round Belts, and Miniature Chain.All come with appropriate pulleys or sprockets invarious materials.<strong>PIC</strong> <strong>Design</strong> Belts and Pulleys — A Brief OverviewNO-SLIP TM POSITIONING BELTSNo-Slip series timing belts feature manydesign elements. The polyurethane beltsoperate backlash free without lubrication andhave excellent chemical and abrasion resistancefor use in medical and food processing applications.Positive tooth engagement offers silent No-Slip drive. No-Slip belts are available with Aramid(Kevlar) or stainless steel cable cores in single ortwin core configurations. Sprockets are availablein either aluminum or stainless steel. Belts areavailable in lengths up to 100 feet and can bespliced in the field for added versatility.NO-SLIDE TM TIMING BELTSA new series of synchronous belts, combinedwith a grooved flangeless pulley, offers highperformance timing. No-flange pulleys allow air toescape and prevents it from being trappedbetween the belt and flange. No-Slide belts aremolded in polyurethane with a stainless steel core(cable). They require no lubrication, handlehigher load capacities than standard timing belts,are available in lengths up to 100 feet, and can bespliced in the field for added versatility.No-Slide belts are excellent for medical,packaging, and labeling applications, andwhere higher load capacity is required.No-Slide pulleys are available in aluminum.E*P*S TIMING BELTSThe E*P*S synchronous timing belt is theclassical timing belt that provides positive,non-slip power transmission. These belts areavailable in neoprene rubber with nylon facingand a fiberglass tensile member, or urethane witha polyester tensile member as shown. A Kevlartensile member is also available as an option.These belts are directly interchangeable with eachother. The urethane belts have excellent flexcharacteristics which allows them to operate onpulleys with as few as 10 teeth, and ratios of 8:1on smaller center distances.The E*P*S line is recommended for use onoffice, mailing, and data processing equipment,printers, plotters, robotics, optical, and photographicequipment.E*P*S HTD ® TIMING BELTSThe E*P*S HTD ® timing belts provide positivenon-slip transmission at both low and highspeeds and offer a higher load carrying capabilitythan the E*P*S trapezoidal design, due to thedeeper curvilinear shape of the belt tooth. E*P*SHTD ® belts can transmit more power with a morecompact package as compared to E*P*S belts,and can be used in applications where shock loadis evident, such as vacuum cleaners, floorpolishers, sanders, centrifuges and power tools,as well as office equipmentdrive systems. Pulleys are available in machinedaluminum.ROUND BELTSRound belt or O-ring drive belt systems areused in a wide variety of applications such asvibration dampening in precision mechanisms andreduction of distortion in audio equipment. Roundbelts also provide overload protection and can actas a clutch in certain applications. Grooved pulleysare available in stainless steel and aluminum.MINIATURE PITCH CHAINMiniature pitch chains are made of non-magneticgrade stainless steel. The large joint bearing areaconstruction permits greater loads and speeds.Precision control of chain length allows forpositioning accuracy between the driver anddriven sprockets. Continuous and positivelubrication is recommended for maximum life andefficiency. Sprockets are available in stainless steeland aluminum.www.pic-design.comInteractive catalog ■ CAD ■ e-commerceDESIGN®No-Slip and No-Slide are trademarks of Precision Industrial Components LLC.HTD is a Registered Trademark of Gates Rubber Co., Denver, CO.Phone: 800-243-6125 ■ FAX: 203-758-8271E-Mail: sales@pic-design.com5-1