PIC Design - RBC Bearings

PIC Design - RBC Bearings

PIC Design - RBC Bearings

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

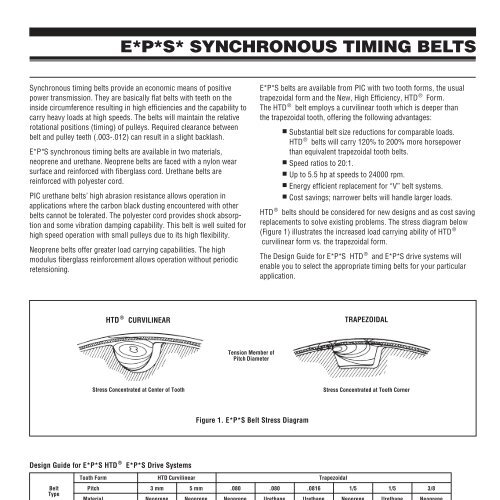

E*P*S* SYNCHRONOUS TIMING BELTSSynchronous timing belts provide an economic means of positivepower transmission. They are basically flat belts with teeth on theinside circumference resulting in high efficiencies and the capability tocarry heavy loads at high speeds. The belts will maintain the relativerotational positions (timing) of pulleys. Required clearance betweenbelt and pulley teeth (.003-.012) can result in a slight backlash.E*P*S synchronous timing belts are available in two materials,neoprene and urethane. Neoprene belts are faced with a nylon wearsurface and reinforced with fiberglass cord. Urethane belts arereinforced with polyester cord.<strong>PIC</strong> urethane belts’ high abrasion resistance allows operation inapplications where the carbon black dusting encountered with otherbelts cannot be tolerated. The polyester cord provides shock absorptionand some vibration damping capability. This belt is well suited forhigh speed operation with small pulleys due to its high flexibility.Neoprene belts offer greater load carrying capabilities. The highmodulus fiberglass reinforcement allows operation without periodicretensioning.E*P*S belts are available from <strong>PIC</strong> with two tooth forms, the usualtrapezoidal form and the New, High Efficiency, HTD ® Form.The HTD ® belt employs a curvilinear tooth which is deeper thanthe trapezoidal tooth, offering the following advantages:■ Substantial belt size reductions for comparable loads.HTD ® belts will carry 120% to 200% more horsepowerthan equivalent trapezoidal tooth belts.■ Speed ratios to 20:1.■ Up to 5.5 hp at speeds to 24000 rpm.■ Energy efficient replacement for “V” belt systems.■ Cost savings; narrower belts will handle larger loads.HTD ® belts should be considered for new designs and as cost savingreplacements to solve existing problems. The stress diagram below(Figure 1) illustrates the increased load carrying ability of HTD ®curvilinear form vs. the trapezoidal form.The <strong>Design</strong> Guide for E*P*S HTD ® and E*P*S drive systems willenable you to select the appropriate timing belts for your particularapplication.HTD ® CURVILINEAR TRAPEZOIDALTension Member ofPitch DiameterStress Concentrated at Center of ToothStress Concentrated at Tooth CornerFigure 1. E*P*S Belt Stress Diagram<strong>Design</strong> Guide for E*P*S HTD ®E*P*S Drive SystemsTooth Form HTD Curvilinear TrapezoidalBelt Pitch 3 mm 5 mm .080 .080 .0816 1/5 1/5 3/8TypeMaterial Neoprene Neoprene Neoprene Urethane Urethane Neoprene Urethane NeopreneCatalog Series EPS-F-N EPS-G-N EPS-A-N EPS-A-U EPS-C-U EPS-D-N EPS-D-U EPS-J-NOperating Temperature ( o F) -30 to +185 -30 to +185 -30 to +185 -30 to +180 -30 to +180 -30 to +185 -30 to +180 -30 to +185Positioning Capability Limited Limited Good Good Good Good Good GoodRecommended Minimum Pitch Dia. (In.) .38 .75 .25 .25 .25 .64 .64 1.19Pulley Minimum No. of Teeth 10 12 10 10 10 10 10 10Recommended Maximum Speed (RPM) 24,000 14,000 20,000 20,000 20,000 10,000 10,000 6,000Recommended Minimum Teeth in Mesh 4 4 5 5 5 5 5 5Recommended Maximum WorkingTension (Lb./In. Width)60 100 32 21 21 41 27 55www.pic-design.comInteractive catalog ■ CAD ■ e-commerceDESIGN®Phone: 800-243-6125 ■ FAX: 203-758-8271E-Mail: sales@pic-design.com 5-23