WAUKESHA Manuale Inglese AP2 - Asco Pompe Srl

WAUKESHA Manuale Inglese AP2 - Asco Pompe Srl

WAUKESHA Manuale Inglese AP2 - Asco Pompe Srl

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

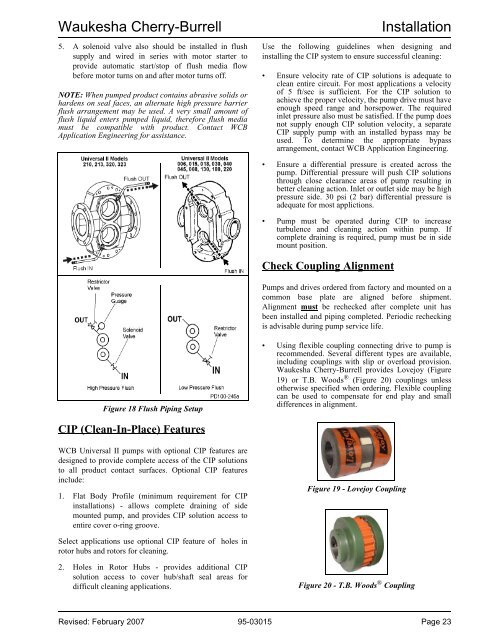

Waukesha Cherry-Burrell Installation5. A solenoid valve also should be installed in flushsupply and wired in series with motor starter toprovide automatic start/stop of flush media flowbefore motor turns on and after motor turns off.NOTE: When pumped product contains abrasive solids orhardens on seal faces, an alternate high pressure barrierflush arrangement may be used. A very small amount offlush liquid enters pumped liquid, therefore flush mediamust be compatible with product. Contact WCBApplication Engineering for assistance.Use the following guidelines when designing andinstalling the CIP system to ensure successful cleaning:• Ensure velocity rate of CIP solutions is adequate toclean entire circuit. For most applications a velocityof 5 ft/sec is sufficient. For the CIP solution toachieve the proper velocity, the pump drive must haveenough speed range and horsepower. The requiredinlet pressure also must be satisfied. If the pump doesnot supply enough CIP solution velocity, a separateCIP supply pump with an installed bypass may beused. To determine the appropriate bypassarrangement, contact WCB Application Engineering.• Ensure a differential pressure is created across thepump. Differential pressure will push CIP solutionsthrough close clearance areas of pump resulting inbetter cleaning action. Inlet or outlet side may be highpressure side. 30 psi (2 bar) differential pressure isadequate for most applictions.• Pump must be operated during CIP to increaseturbulence and cleaning action within pump. Ifcomplete draining is required, pump must be in sidemount position.Check Coupling AlignmentPumps and drives ordered from factory and mounted on acommon base plate are aligned before shipment.Alignment must be rechecked after complete unit hasbeen installed and piping completed. Periodic recheckingis advisable during pump service life.Figure 18 Flush Piping Setup• Using flexible coupling connecting drive to pump isrecommended. Several different types are available,including couplings with slip or overload provision.Waukesha Cherry-Burrell provides Lovejoy (Figure19) or T.B. Woods ® (Figure 20) couplings unlessotherwise specified when ordering. Flexible couplingcan be used to compensate for end play and smalldifferences in alignment.CIP (Clean-In-Place) FeaturesWCB Universal II pumps with optional CIP features aredesigned to provide complete access of the CIP solutionsto all product contact surfaces. Optional CIP featuresinclude:1. Flat Body Profile (minimum requirement for CIPinstallations) - allows complete draining of sidemounted pump, and provides CIP solution access toentire cover o-ring groove.Figure 19 - Lovejoy CouplingSelect applications use optional CIP feature of holes inrotor hubs and rotors for cleaning.2. Holes in Rotor Hubs - provides additional CIPsolution access to cover hub/shaft seal areas fordifficult cleaning applications.Figure 20 - T.B. Woods ® CouplingRevised: February 2007 95-03015 Page 23