- Page 1 and 2: spec X-Ray Diffraction SoftwareUSER

- Page 3 and 4: specX-Ray Diffraction SoftwareCerti

- Page 5 and 6: TABLE OF CONTENTSUSER MANUAL AND TU

- Page 7 and 8: Reciprocal Space Macros ...........

- Page 9 and 10: Preface For the Interim ManualWe ap

- Page 11 and 12: USER MANUAL AND TUTORIALS

- Page 15 and 16: files is then identified (/usr/loca

- Page 17 and 18: denotes variable parameters you sup

- Page 19 and 20: spec also keeps track of software m

- Page 21 and 22: 13.FOURC> mvr th 114.FOURC>will mov

- Page 23 and 24: 8 0.98 0 0 17603 38839 19 0.99 0 0

- Page 25 and 26: 4.FOURC> p date(1e9)Sat Sep 8 21:46

- Page 27 and 28: Controlling Output Tothe Printer an

- Page 29 and 30: By convention, global variables in

- Page 31 and 32: 16.FOURC> for (i = 0; i < MOTORS; i

- Page 33 and 34: When a macro definition contains ar

- Page 35 and 36: 38.FOURC> undef com39.FOURC> prdef

- Page 37 and 38: 43.FOURC> lsdef *scanEscan (1448) a

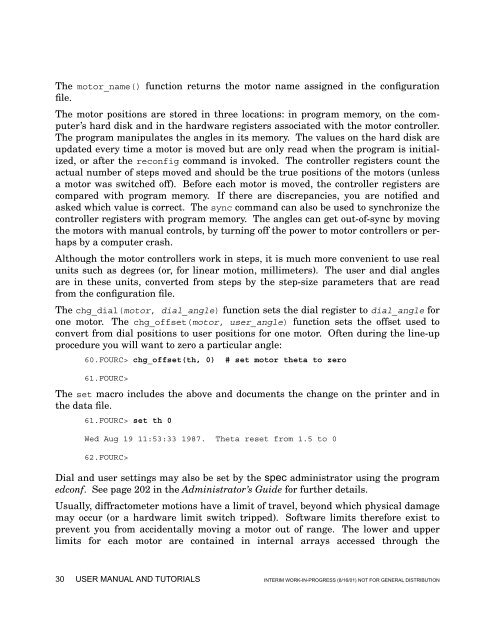

- Page 39: diffractometer. For example, they m

- Page 43 and 44: 66.FOURC> getcounts; printf("%s = %

- Page 45 and 46: the number of bytes is less than n

- Page 47 and 48: PLOT-> fnscans.4 options scan-numbe

- Page 49 and 50: #S number Starts a new scan. number

- Page 51 and 52: ShowscansThe showscans program is a

- Page 53 and 54: REFERENCE MANUAL

- Page 55 and 56: IntroductionThe material contained

- Page 57 and 58: ArraysArrays are formed using squar

- Page 59 and 60: Numer ic ConstantsNumeric constants

- Page 61 and 62: !! Redo the previous command.!14 Re

- Page 63 and 64: In some installations, spec is inst

- Page 65 and 66: ExitingA spec session is normally t

- Page 67 and 68: DEBUG — is a user-assignable nume

- Page 69 and 70: USER — is string valued and is se

- Page 71 and 72: The concatenation operator comes in

- Page 73 and 74: The second form of the for statemen

- Page 75 and 76: These are the grammar rules:express

- Page 77 and 78: local identifier-list [ ; ]syms pat

- Page 79 and 80: Utility Functions and CommandsAll f

- Page 81 and 82: .sp N — spaces N lines. Without a

- Page 83 and 84: ¢The formatting commands:.RB .BR .

- Page 85 and 86: "ischr" or "−c" — Returns true

- Page 87 and 88: polled devices, spec needs to perfo

- Page 89 and 90: "show_prdef_files" — When this mo

- Page 91 and 92:

EOS sequence are read or until the

- Page 93 and 94:

¡with dlog or ends with .dlog . De

- Page 95 and 96:

10.FOURC> def change_it ’{11.quot

- Page 97 and 98:

tty_cntl(cmd) — Sends terminal-sp

- Page 99 and 100:

Commands For Var ia blesglobal name

- Page 101 and 102:

¤£ ¢prdef pattern ... — As abo

- Page 103 and 104:

at the end of the line.Within a mac

- Page 105 and 106:

config file. Built-in code for the

- Page 107 and 108:

RS-232 Serial InterfacesSerial func

- Page 109 and 110:

vme_put32(addr, data [, dmode ])

- Page 111 and 112:

In addition, device-dependent value

- Page 113 and 114:

correction. If val is given, then t

- Page 115 and 116:

¡and is set in the config file. Th

- Page 117 and 118:

¡data_grp(grp, npts, wid) — Conf

- Page 119 and 120:

"min" — Returns the minimum value

- Page 121 and 122:

"xlog" — Use a logarithmic x axis

- Page 123 and 124:

continued line, appropriate for sav

- Page 125 and 126:

LIBS= parameters. If the tools prov

- Page 127 and 128:

¡void set_return_data(double *x, i

- Page 129 and 130:

split(string, array) — Splits the

- Page 131 and 132:

STANDARD MACRO GUIDE

- Page 133 and 134:

IntroductionThe standard macros inc

- Page 135 and 136:

the argument is not a valid mnemoni

- Page 137 and 138:

Utility MacrosUNIX CommandsThese si

- Page 139 and 140:

# View (and modify), then reread co

- Page 141 and 142:

if ("$1" != ".") {DOFILE = "$1"if (

- Page 143 and 144:

Star t-up MacrosThese macros ask fo

- Page 145 and 146:

Motor Macrosmv motor posmvr motor p

- Page 147 and 148:

Change a motor limitdef set_lm ’i

- Page 149 and 150:

# Where - all motorsdef wa ’waitm

- Page 151 and 152:

# "count" is the basic macro to cou

- Page 153 and 154:

Reciprocal Space MacrosThe followin

- Page 155 and 156:

Scan MacrosThe following sections s

- Page 157 and 158:

Basic Reciprocal Space Scanshscan s

- Page 159 and 160:

def Pheader ’printf("\n Setpoint

- Page 161 and 162:

’}Here are examples of _settemp m

- Page 163 and 164:

Pr inter Initializa tion MacrosThes

- Page 165 and 166:

’X_L = motor_name(_m1)_sx = _s1 ;

- Page 167 and 168:

space scans, the limit check must l

- Page 169 and 170:

}}Pheaderprintf("\noffpprintf(" ")_

- Page 171 and 172:

# The loop macro, called by all the

- Page 173 and 174:

FOUR-CIRCLE REFERENCE

- Page 175 and 176:

IntroductionWhen invoked by the nam

- Page 177 and 178:

Once properly configured, diffracto

- Page 179 and 180:

Four-CircleModesAs noted above, bec

- Page 181 and 182:

asurface, keeping α small will kee

- Page 183 and 184:

¢¢¢¢Sector sSectors correspond

- Page 185 and 186:

Four-CircleFilesMost questions rega

- Page 187 and 188:

U[14] g_l0 or0, setor0 L of primary

- Page 189 and 190:

’gpset A[mA[1]] g_u01gpset A[mA[2

- Page 191 and 192:

global REFLEX # Variable for file n

- Page 193 and 194:

To calculate the new lattice parame

- Page 195 and 196:

ADMINISTRATOR’S GUIDE

- Page 197 and 198:

IntroductionThe first section of th

- Page 199 and 200:

The distribution will be in tar for

- Page 201 and 202:

¢KSC 3929 SCSI-CAMAC file location

- Page 203 and 204:

Installing Driver sIn the early his

- Page 205 and 206:

Fine Tuning the HardwareConfigurati

- Page 207 and 208:

...*gparam[3] = 1.54;...if (*gparam

- Page 209 and 210:

Makefile, and /usr/local/lib/spec.d

- Page 211 and 212:

Ena bling E/ISA I/O Por ts On HP 70

- Page 213 and 214:

ˆW Gain wizard access to set prote

- Page 215 and 216:

CA_LC2301CA_LC3512CA_LC3521CA_LC358

- Page 217 and 218:

MCU_O As above, but with old PROMsM

- Page 219 and 220:

config file that has the most motor

- Page 221 and 222:

the edconf program set-user id spec

- Page 223 and 224:

HARDWARE REFERENCE

- Page 225 and 226:

Introductionspec includes built-in

- Page 227 and 228:

DSP 6001/6002 CAMAC With No Driverc

- Page 229 and 230:

Kinetic Systems CAMAC Softwareconfi

- Page 231 and 232:

Any of the National Instruments boa

- Page 233 and 234:

National Instruments SB-GPIB Ver 1.

- Page 235 and 236:

modified version of the standard li

- Page 237 and 238:

Bit 3 Model 616/617 PCI-VMEBit 3 Mo

- Page 239 and 240:

Motor Controller sAdvanced Control

- Page 241 and 242:

panel controls. Youshould consult t

- Page 243 and 244:

Huber SMC 9000 (GPIB)config file:GP

- Page 245 and 246:

motors on the board) and clears the

- Page 247 and 248:

translation stages, the maximum val

- Page 249 and 250:

MOTORS DEVICE ADDR MODE NUM TYPEYES

- Page 251 and 252:

The driver is contained in the file

- Page 253 and 254:

30.FOURC> print motor_par(tth, "rea

- Page 255 and 256:

free-axis-displacement commands "L+

- Page 257 and 258:

PMC Corporation DCX-100 (Serial and

- Page 259 and 260:

Motor ParametersThe steps per deg/m

- Page 261 and 262:

Timer s and CountersAm9513-based Co

- Page 263 and 264:

DSP RTC-018 Real Time Clock (CAMAC)

- Page 265 and 266:

Kinetic Systems 3610 6-Channel 50 M

- Page 267 and 268:

Or tec 974/994/995/997 NIM Timer s

- Page 269 and 270:

Setting Operational ParametersThe c

- Page 271 and 272:

mca_par("first_ch") — returns the

- Page 273 and 274:

Oxford/Tennelec/Nucleus PCA Mutlipo

- Page 275 and 276:

mca_par("preset") — in PHA mode,

- Page 277 and 278:

¢REFERENCESJournal articles descri

- Page 279 and 280:

camac program, 199cat macro, 127cd

- Page 281 and 282:

opening, 6selecting, 6standard form

- Page 283 and 284:

saving to output device, 132scan, 1

- Page 285 and 286:

number,35, 37output, customizing, 1

- Page 287 and 288:

wait() function, 33, 68, 77, 78, 99

- Page 289 and 290:

¡spec (1) (CSS Utilities) spec (1)