Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

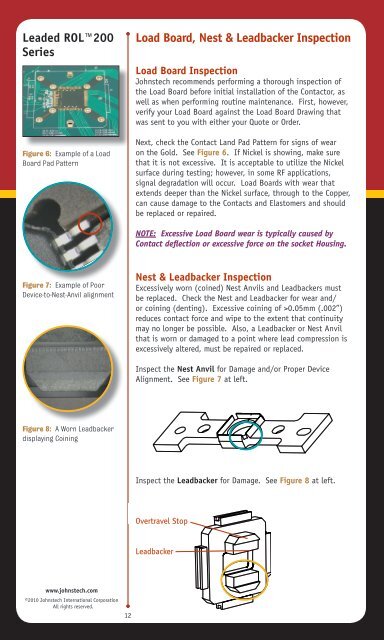

<strong>Leaded</strong> ROL200SeriesFigure 6: Example of a LoadBoard Pad PatternLoad Board, Nest & Leadbacker <strong>Inspection</strong>Load Board <strong>Inspection</strong><strong>Johnstech</strong> recommends performing a thorough inspection ofthe Load Board before initial installation of the Contactor, aswell as when performing routine maintenance. First, however,verify your Load Board against the Load Board Drawing thatwas sent to you with either your Quote or Order.Next, check the Contact Land Pad Pattern for signs of wearon the Gold. See Figure 6. If Nickel is showing, make surethat it is not excessive. It is acceptable to utilize the Nickelsurface during testing; however, in some RF applications,signal degradation will occur. Load Boards with wear thatextends deeper than the Nickel surface, through to the Copper,can cause damage to the Contacts and Elastomers and shouldbe replaced or repaired.NOTE: Excessive Load Board wear is typically caused byContact deflection or excessive force on the socket Housing.Figure 7: Example of PoorDevice-to-Nest-Anvil alignmentNest & Leadbacker <strong>Inspection</strong>Excessively worn (coined) Nest Anvils and Leadbackers mustbe replaced. Check the Nest and Leadbacker for wear and/or coining (denting). Excessive coining of >0.05mm (.002”)reduces contact force and wipe to the extent that continuitymay no longer be possible. Also, a Leadbacker or Nest Anvilthat is worn or damaged to a point where lead compression isexcessively altered, must be repaired or replaced.Inspect the Nest Anvil for Damage and/or Proper DeviceAlignment. See Figure 7 at left.Figure 8: A Worn Leadbackerdisplaying CoiningInspect the Leadbacker for Damage. See Figure 8 at left.Overtravel StopLeadbackerwww.johnstech.com©2010 <strong>Johnstech</strong> International CorporationAll rights reserved.12