Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

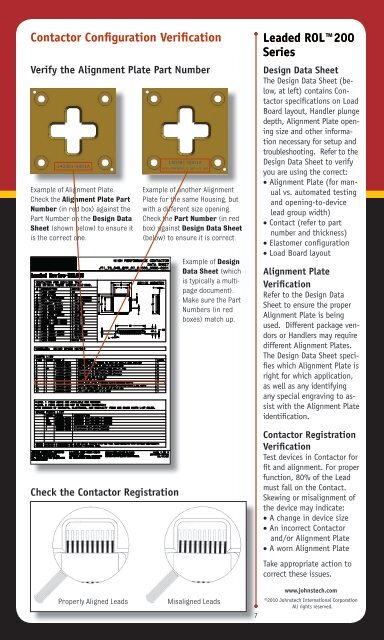

Contactor Configuration VerificationVerify the Alignment Plate Part Number140381-0001AExample of Alignment Plate.Check the Alignment Plate PartNumber (in red box) against thePart Number on the Design DataSheet (shown below) to ensure itis the correct one.Check the Contactor Registration140381-0001AALPL OPENING 5.160 x 5.160Example of another AlignmentPlate for the same Housing, butwith a different size opening.Check the Part Number (in redbox) against Design Data Sheet(below) to ensure it is correct.Example of DesignData Sheet (whichis typically a multipagedocument).Make sure the PartNumbers (in redboxes) match up.<strong>Leaded</strong> ROL200SeriesDesign Data SheetThe Design Data Sheet (below,at left) contains Contactorspecifications on LoadBoard layout, Handler plungedepth, Alignment Plate openingsize and other informationnecessary for setup andtroubleshooting. Refer to theDesign Data Sheet to verifyyou are using the correct:• Alignment Plate (for manualvs. automated testingand opening-to-devicelead group width)• Contact (refer to partnumber and thickness)• Elastomer configuration• Load Board layoutAlignment PlateVerificationRefer to the Design DataSheet to ensure the properAlignment Plate is beingused. Different package vendorsor Handlers may requiredifferent Alignment Plates.The Design Data Sheet specifieswhich Alignment Plate isright for which application,as well as any identifyingany special engraving to assistwith the Alignment Plateidentification.Contactor RegistrationVerificationTest devices in Contactor forfit and alignment. For properfunction, 80% of the Leadmust fall on the Contact.Skewing or misalignment ofthe device may indicate:• A change in device size• An incorrect Contactorand/or Alignment Plate• A worn Alignment PlateTake appropriate action tocorrect these issues.Properly Aligned LeadsMisaligned Leads7www.johnstech.com©2010 <strong>Johnstech</strong> International CorporationAll rights reserved.