Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

Maintenance & Inspection Guide Leaded ROLâ¢200 ... - Johnstech

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

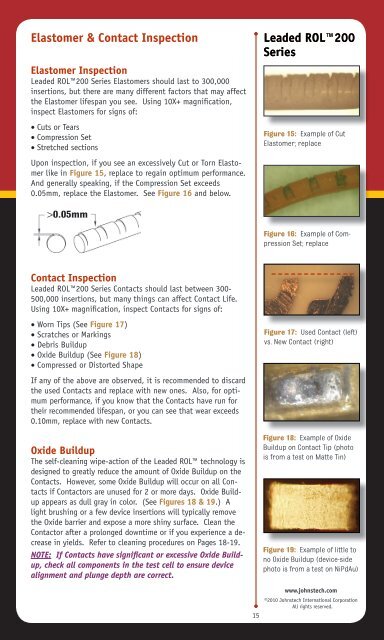

Elastomer & Contact <strong>Inspection</strong>Elastomer <strong>Inspection</strong><strong>Leaded</strong> ROL200 Series Elastomers should last to 300,000insertions, but there are many different factors that may affectthe Elastomer lifespan you see. Using 10X+ magnification,inspect Elastomers for signs of:· Cuts or Tears· Compression Set· Stretched sections<strong>Leaded</strong> ROL200SeriesFigure 15: Example of CutElastomer; replaceUpon inspection, if you see an excessively Cut or Torn Elastomerlike in Figure 15, replace to regain optimum performance.And generally speaking, if the Compression Set exceeds0.05mm, replace the Elastomer. See Figure 16 and below.>0.05mmFigure 16: Example of CompressionSet; replaceContact <strong>Inspection</strong><strong>Leaded</strong> ROL200 Series Contacts should last between 300-500,000 insertions, but many things can affect Contact Life.Using 10X+ magnification, inspect Contacts for signs of:· Worn Tips (See Figure 17)· Scratches or Markings· Debris Buildup· Oxide Buildup (See Figure 18)· Compressed or Distorted ShapeFigure 17: Used Contact (left)vs. New Contact (right)If any of the above are observed, it is recommended to discardthe used Contacts and replace with new ones. Also, for optimumperformance, if you know that the Contacts have run fortheir recommended lifespan, or you can see that wear exceeds0.10mm, replace with new Contacts.Oxide BuildupThe self-cleaning wipe-action of the <strong>Leaded</strong> ROL technology isdesigned to greatly reduce the amount of Oxide Buildup on theContacts. However, some Oxide Buildup will occur on all Contactsif Contactors are unused for 2 or more days. Oxide Buildupappears as dull gray in color. (See Figures 18 & 19.) Alight brushing or a few device insertions will typically removethe Oxide barrier and expose a more shiny surface. Clean theContactor after a prolonged downtime or if you experience a decreasein yields. Refer to cleaning procedures on Pages 18-19.NOTE: If Contacts have significant or excessive Oxide Buildup,check all components in the test cell to ensure devicealignment and plunge depth are correct.Figure 18: Example of OxideBuildup on Contact Tip (photois from a test on Matte Tin)Figure 19: Example of little tono Oxide Buildup (device-sidephoto is from a test on NiPdAu)15www.johnstech.com©2010 <strong>Johnstech</strong> International CorporationAll rights reserved.