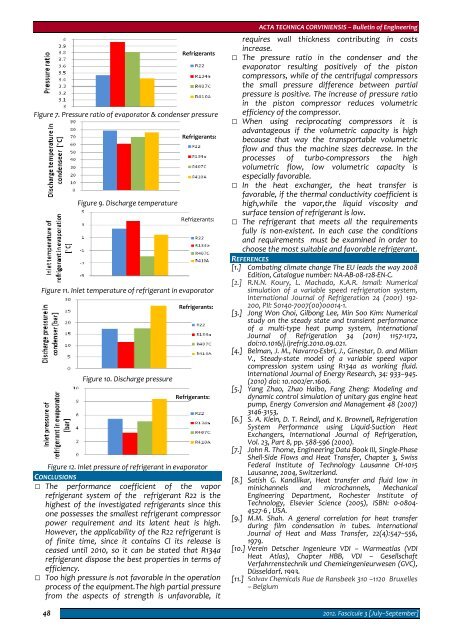

Figure 7. Pressure ratio of evaporator & condenser pressure48Figure 9. Discharge temperatureFigure 11. Inlet temperature of refrigerant in evaporatorFigure 10. Discharge pressureRefrigerantsRefrigerants:Refrigerants:Refrigerants:Refrigerants:Figure 12. Inlet pressure of refrigerant in evaporatorCONCLUSIONS The performance coefficient of the vaporrefrigerant system of the refrigerant R22 is thehighest of the investigated refrigerants since thisone possesses the smallest refrigerant compressorpower requirement and its latent heat is high.However, the applicability of the R22 refrigerant isof finite time, since it contains Cl its release isceased until 2010, so it can be stated that R134arefrigerant dispose the best properties in terms ofefficiency. Too high pressure is not favorable in the operationprocess of the equipment.The high partial pressurefrom the aspects of strength is unfavorable, itACTA TECHNICA CORVINIENSIS – Bulletin of Engineeringrequires wall thickness contributing in costsincrease. The pressure ratio in the condenser and theevaporator resulting positively of the pistoncompressors, while of the centrifugal compressorsthe small pressure difference between partialpressure is positive. The increase of pressure ratioin the piston compressor reduces volumetricefficiency of the compressor. When using reciprocating compressors it isadvantageous if the volumetric capacity is highbecause that way the transportable volumetricflow and thus the machine sizes decrease. In theprocesses of turbo‐compressors the highvolumetric flow, low volumetric capacity isespecially favorable. In the heat exchanger, the heat transfer isfavorable, if the thermal conductivity coefficient ishigh,while the vapor,the liquid viscosity andsurface tension of refrigerant is low. The refrigerant that meets all the requirementsfully is non‐existent. In each case the conditionsand requirements must be examined in order tochoose the most suitable and favorable refrigerant.REFERENCES[1.] Combating climate change The EU leads the way 2008Edition, Catalogue number: NA‐AB‐08‐128‐EN‐C.[2.] R.N.N. Koury, L. Machado, K.A.R. Ismail: Numericalsimulation of a variable speed refrigeration system,International Journal of Refrigeration 24 (2001) 192‐200, PII: S0140‐7007(00)00014‐1.[3.] Jong Won Choi, Gilbong Lee, Min Soo Kim: Numericalstudy on the steady state and transient performanceof a multi‐type heat pump system, InternationalJournal of Refrigeration 34 (2011) 1157‐1172,doi:10.1016/j.ijrefrig.2010.09.021.[4.] Belman, J. M., Navarro‐Esbrí, J., Ginestar, D. and MilianV., Steady‐state model of a variable speed vaporcompression system using R134a as working fluid.International Journal of Energy Research, 34: 933–945.(2010) doi: 10.1002/er.1606.[5.] Yang Zhao, Zhao Haibo, Fang Zheng: Modeling anddynamic control simulation of unitary gas engine heatpump, Energy Conversion and Management 48 (2007)3146‐3153,[6.] S. A. Klein, D. T. Reindl, and K. Brownell, RefrigerationSystem Performance using Liquid‐Suction HeatExchangers, International Journal of Refrigeration,Vol. 23, Part 8, pp. 588‐596 (2000).[7.] John R. Thome, Engineering Data Book III, Single‐PhaseShell‐Side Flows and Heat Transfer, Chapter 3, SwissFederal Institute of Technology Lausanne CH‐1015Lausanne, 2004, Switzerland.[8.] Satish G. Kandlikar, Heat transfer and fluid low inminichannels and microchannels, MechanicalEngineering Department, Rochester Institute ofTechnology, Elsevier Science (2005), ISBN: 0‐0804‐4527‐6 , USA.[9.] M.M. Shah. A general correlation for heat transferduring film condensation in tubes. InternationalJournal of Heat and Mass Transfer, 22(4):547–556,1979.[10.] Verein Detscher Ingenieure VDI – Warmeatlas (VDIHeat Atlas), Chapter HBB, VDI – GesellschaftVerfahrrenstechnik und Chemieingenieurwesen (GVC),Düsseldorf, 1993.[11.] Solvay Chemicals Rue de Ransbeek 310 –1120 Bruxelles– Belgium2012. Fascicule 3 [July–September]

1.Sorina ŞERBANANALYSIS AND DESIGN OF INFORMATION SYSTEMS1.UNIVERSITY POLITEHNICA TIMISOARA, FACULTY OF ENGINEERING HUNEDOARA, HUNEDOARA, ROMANIAABSTRACT: Systems analysis and design work in chemistry is the result of a complex application called ChimUniv in thecreation and operation of relational databases, the implementation of applications dedicated to Chemistry. The paper isaddressed to students and all those who want to build applications using the skills and habits of Chemistry, MicrosoftAccess solution to offer. Fundamental theoretical notions database are missing from the scientific approach of this paper.In this paper we intend to highlight issues concerning the organization of elements in the periodic table, arranging them ingroups and periods depending on their chemical properties.KEYWORDS: applications, implementation, information system, computer system, databaseINTRODUCTIONIn our everyday life, computers are commonplace andeven essential in some cases. One could say rightlythat we live in a computerized society. It should benoted that computer is actually a machine thatprocesses a series of information that we give them.Information is an essential element in this entire chain.In fact, in practice meet, among others, two relatedconcepts, namely the information system andcomputer system.The information system includes all elements involvedin the collection, transmission, processing, etc..information, so the role of information system is totransmit information.The set of all elements involved in the process ofprocessing and transmitting data electronically makeup a computer system. In a computer system can get:computer, data transmission systems, otherhardware, software, data processing, etc..It can be said therefore that the information system isincluded in the computer system, the latter being anessential component of the first.In the last fifty years, the production and use ofcomputer ‐ hardware and software ‐ has grownbeyond imagination. With the emergence ofcomputers, programmers have the ability to designproducts faster and cheaper software for datamaintenance and distribution.The model used for data storage is a relationaldatabase. In database systems, data defining separateapplication programs, users saw only the externaldefinition of an object, without knowing how it isdefined and how it works.In this way, the definition of the object can bechanged without affecting its users if it does notchange the external definition. For example, if you arenew or changed data of Structural existing ones,where application programs are not affected, if notdirectly dependent on what is changing.In databases there is a data query, meaning that morefiles are seen as a whole, eliminating redundantinformation as possible. It also allows simultaneousaccess to the same data, located in the same place ormore spatially distributed users, each with personalwork style. Software system that allows theconstruction of databases, input information intodatabases called management system database. [4]A management system database enables a user toaccess data using a high‐level language close to theusual way of expression, to obtain information,making abstraction of user selection algorithms applythe data involved and mode of storage them. DBMS isan interface between operating system users.Access is a special type of database called RelationalDatabase. A relational database shares information indistinct subsets. Each subset groups the informationon a particular topic. In Access, these subsets of dataresiding in individual tables. Access allows us to createrelationships between tables. These relationships arebased on a common field in two tables.When you create a database, we want to make surethat it is designed not only to meet our requirementsrelated to data entry, but corresponds to viewing andreporting requirements of the data stored in varioustables that form the database.APPLICATION SUBMISSIONOne of the features is an information explosion inrecent years. Huge volume of information can not beused effectively through traditional methods.Automatic processing of information using electroniccomputing systems has become a necessity for allfields. Thus, the most advanced method of organizinginformation for a meeting of automatic processingdatabases.Figure 1. Relationships between tables© copyright FACULTY of ENGINEERING ‐ HUNEDOARA, ROMANIA 49

- Page 2 and 3: ACTA TECHNICA CORVINIENSIS- BULLETI

- Page 4 and 5: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 6 and 7: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 8 and 9: Regional Editors from MALAYSIAAbdel

- Page 10 and 11: Imre TIMÁRUniversity of Pannonia,

- Page 12 and 13: Ioan MILOŞANTransilvania Universit

- Page 14 and 15: Member from GREECENicolaos VAXEVANI

- Page 16 and 17: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 18 and 19: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 20 and 21: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 22 and 23: two decades are seismically deficie

- Page 24 and 25: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 26 and 27: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 28 and 29: The Euler ecuation about the condit

- Page 30 and 31: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 32 and 33: examination centre of the Hungarian

- Page 34 and 35: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 36 and 37: elieve that they are communicating

- Page 38 and 39: converting the data also increases

- Page 40 and 41: REFERENCES[1.] Bhavyesh Divecha, Aj

- Page 42 and 43: In addition, API (Application Progr

- Page 44 and 45: The new protocol has to be implemen

- Page 46 and 47: compressor, the now hot and highly

- Page 50 and 51: Physical data model (MFD) is obtain

- Page 52 and 53: The new project which now includes

- Page 54 and 55: Figure 3. Materials evolutionThe pr

- Page 56 and 57: (GPa) and weight used in the textil

- Page 58 and 59: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 60 and 61: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 62 and 63: A machine vision‐guided plant sen

- Page 64 and 65: During the experiment, non‐unifor

- Page 66 and 67: espectively velocities hodograph (v

- Page 68 and 69: generation and thermal‐diffusion

- Page 70 and 71: 70(Pr−1)=bGm( R −cPr)( − M+c

- Page 72 and 73: 72Figure 12: Sherwood Number for di

- Page 74 and 75: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 76 and 77: The hardware components offer the p

- Page 78 and 79: Markers 1 (t=‐60 ms) and 2 (t=‐

- Page 80 and 81: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 82 and 83: compensation, apply dynamic control

- Page 84 and 85: A. Impact on transmission line prot

- Page 86 and 87: [12.] W.H. Zhang, S.J. Lee, M.S. Ch

- Page 88 and 89: Substituting equations (2), (3), (4

- Page 90 and 91: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 92 and 93: the tribological experiment to simu

- Page 94 and 95: It is difficult to determine temper

- Page 96 and 97: ACTA TECHNICA CORVINIENSIS - Bullet

- Page 98 and 99:

where: “ν ” represents the con

- Page 100 and 101:

Figure 10. The velocity field in a

- Page 102 and 103:

made on demand. In this type of pro

- Page 104 and 105:

traditional MANET routing protocol

- Page 106 and 107:

and classification,” In Journal o

- Page 108 and 109:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 110 and 111:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 112 and 113:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 114 and 115:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 116 and 117:

equipped with tube made from stainl

- Page 118 and 119:

Fig. 10 ‐ The die, the blank hold

- Page 120 and 121:

desktop, it must be based on runtim

- Page 122 and 123:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 124 and 125:

database, which makes it possible t

- Page 126 and 127:

technology - „Applied logistics

- Page 128 and 129:

increase in one of the factors lead

- Page 130 and 131:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 132 and 133:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 134 and 135:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 136 and 137:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 138 and 139:

ACTA TECHNICA CORVINIENSIS - Bullet

- Page 140 and 141:

ACTA TECHNICA CORVINIENSIS - Bullet