condair oem

condair oem

condair oem

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

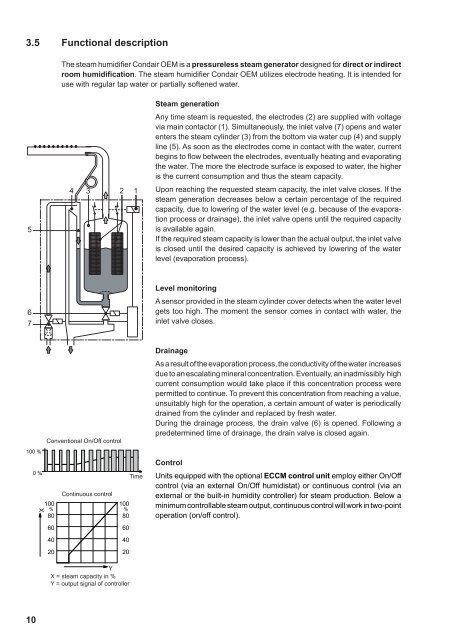

3.5 Functional descriptionThe steam humidifier Condair OEM is a pressureless steam generator designed for direct or indirectroom humidification. The steam humidifier Condair OEM utilizes electrode heating. It is intended foruse with regular tap water or partially softened water.Steam generationAny time steam is requested, the electrodes (2) are supplied with voltagevia main contactor (1). Simultaneously, the inlet valve (7) opens and waterenters the steam cylinder (3) from the bottom via water cup (4) and supplyline (5). As soon as the electrodes come in contact with the water, currentbegins to flow between the electrodes, eventually heating and evaporatingthe water. The more the electrode surface is exposed to water, the higheris the current consumption and thus the steam capacity.Upon reaching the requested steam capacity, the inlet valve closes. If thesteam generation decreases below a certain percentage of the requiredcapacity, due to lowering of the water level (e.g. because of the evaporationprocess or drainage), the inlet valve opens until the required capacityis available again.If the required steam capacity is lower than the actual output, the inlet valveis closed until the desired capacity is achieved by lowering of the waterlevel (evaporation process).54321Level monitoring67A sensor provided in the steam cylinder cover detects when the water levelgets too high. The moment the sensor comes in contact with water, theinlet valve closes.Conventional On/Off control100 %0 %TimeContinuous controlX100100% %8080606040402020DrainageAs a result of the evaporation process, the conductivity of the water increasesdue to an escalating mineral concentration. Eventually, an inadmissibly highcurrent consumption would take place if this concentration process werepermitted to continue. To prevent this concentration from reaching a value,unsuitably high for the operation, a certain amount of water is periodicallydrained from the cylinder and replaced by fresh water.During the drainage process, the drain valve (6) is opened. Following apredetermined time of drainage, the drain valve is closed again.ControlUnits equipped with the optional ECCM control unit employ either On/Offcontrol (via an external On/Off humidistat) or continuous control (via anexternal or the built-in humidity controller) for steam production. Below aminimum controllable steam output, continuous control will work in two-pointoperation (on/off control).YX = steam capacity in %Y = output signal of controller10