condair oem

condair oem

condair oem

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

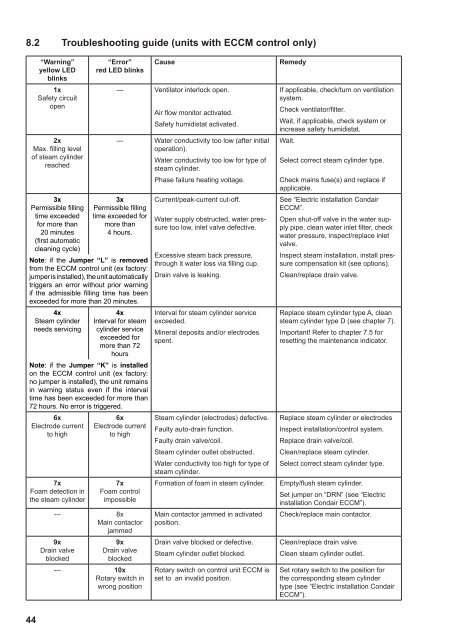

8.2 Troubleshooting guide (units with ECCM control only)“Warning”yellow LEDblinks1xSafety circuitopen2xMax. filling levelof steam cylinderreached3xPermissible fillingtime exceededfor more than20 minutes(first automaticcleaning cycle)“Error”red LED blinksCause--- Ventilator interlock open.Air flow monitor activated.Safety humidistat activated.--- Water conductivity too low (after initialoperation).Water conductivity too low for type ofsteam cylinder.Phase failure heating voltage.3xPermissible fillingtime exceeded formore than4 hours.Note: if the Jumper “L” is removedfrom the ECCM control unit (ex factory:jumper is installed), the unit automaticallytriggers an error without prior warningif the admissible filling time has beenexceeded for more than 20 minutes.4xSteam cylinderneeds servicing4xInterval for steamcylinder serviceexceeded formore than 72hoursNote: if the Jumper “K” is installedon the ECCM control unit (ex factory:no jumper is installed), the unit remainsin warning status even if the intervaltime has been exceeded for more than72 hours. No error is triggered.6xElectrode currentto high7xFoam detection inthe steam cylinder6xElectrode currentto high7xFoam controlimpossible--- 8xMain contactorjammed9xDrain valveblocked9xDrain valveblocked--- 10xRotary switch inwrong positionCurrent/peak-current cut-off.Water supply obstructed, water pressuretoo low, inlet valve defective.Excessive steam back pressure,through it water loss via filling cup.Drain valve is leaking.Interval for steam cylinder serviceexceeded.Mineral deposits and/or electrodesspent.Steam cylinder (electrodes) defective.Faulty auto-drain function.Faulty drain valve/coil.Steam cylinder outlet obstructed.Water conductivity too high for type ofsteam cylinder.Formation of foam in steam cylinder.Main contactor jammed in activatedposition.Drain valve blocked or defective.Steam cylinder outlet blocked.Rotary switch on control unit ECCM isset to an invalid position.RemedyIf applicable, check/turn on ventilationsystem.Check ventilator/filter.Wait, if applicable, check system orincrease safety humidistat.Wait.Select correct steam cylinder type.Check mains fuse(s) and replace ifapplicable.See “Electric installation CondairECCM”.Open shut-off valve in the water supplypipe, clean water inlet filter, checkwater pressure, inspect/replace inletvalve.Inspect steam installation, install pressurecompensation kit (see options).Clean/replace drain valve.Replace steam cylinder type A, cleansteam cylinder type D (see chapter 7).Important! Refer to chapter 7.5 forresetting the maintenance indicator.Replace steam cylinder or electrodesInspect installation/control system.Replace drain valve/coil.Clean/replace steam cylinder.Select correct steam cylinder type.Empty/flush steam cylinder.Set jumper on “DRN” (see “Electricinstallation Condair ECCM”).Check/replace main contactor.Clean/replace drain valve.Clean steam cylinder outlet.Set rotary switch to the position forthe corresponding steam cylindertype (see “Electric installation CondairECCM”).44