HD-X2 - IRO AB

HD-X2 - IRO AB

HD-X2 - IRO AB

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

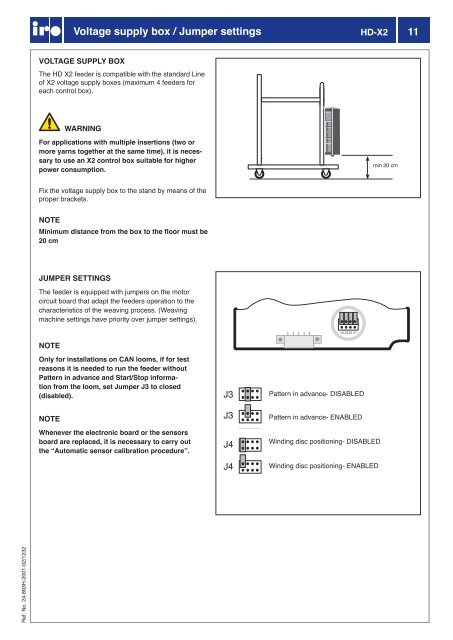

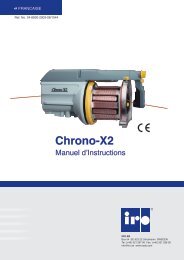

Voltage supply box / Jumper settings<strong>HD</strong>-<strong>X2</strong> 11VOLTAGE SUPPLY BOXThe <strong>HD</strong> <strong>X2</strong> feeder is compatible with the standard Lineof <strong>X2</strong> voltage supply boxes (maximum 4 feeders foreach control box).WARNINGFor applications with multiple insertions (two ormore yarns together at the same time), it is necessaryto use an <strong>X2</strong> control box suitable for higherpower consumption.min 20 cmFix the voltage supply box to the stand by means of theproper brackets.NoteMinimum distance from the box to the floor must be20 cmjumper settingsThe feeder is equipped with jumpers on the motorcircuit board that adapt the feeders operation to thecharacteristics of the weaving process. (Weavingmachine settings have priority over jumper settings).NoteOnly for installations on CAN looms, if for testreasons it is needed to run the feeder withoutPattern in advance and Start/Stop informationfrom the loom, set Jumper J3 to closed(disabled).NOTEWhenever the electronic board or the sensorsboard are replaced, it is necessary to carry outthe “Automatic sensor calibration procedure”.J3J3J4J4Pattern in advance- DIS<strong>AB</strong>LEDPattern in advance- EN<strong>AB</strong>LEDWinding disc positioning- DIS<strong>AB</strong>LEDWinding disc positioning- EN<strong>AB</strong>LEDRef. No. 24-893H-2001-02/1232