general recommendations - safety - AJ Maskin AS

general recommendations - safety - AJ Maskin AS

general recommendations - safety - AJ Maskin AS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

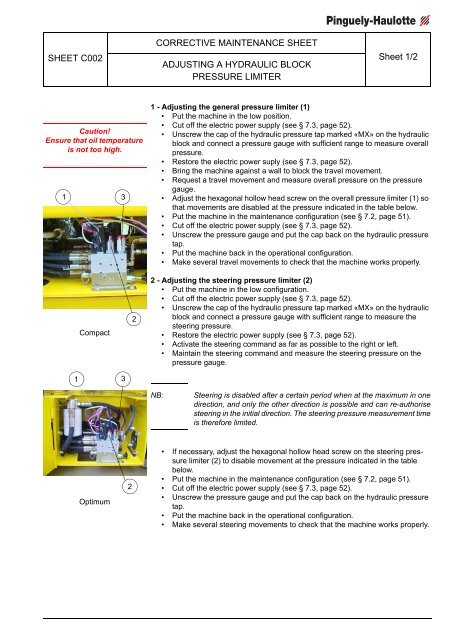

SHEET C002CORRECTIVE MAINTENANCE SHEETADJUSTING A HYDRAULIC BLOCKPRESSURE LIMITERSheet 1/2Caution!Ensure that oil temperatureis not too high.131 - Adjusting the <strong>general</strong> pressure limiter (1)• Put the machine in the low position.• Cut off the electric power supply (see § 7.3, page 52).• Unscrew the cap of the hydraulic pressure tap marked «MX» on the hydraulicblock and connect a pressure gauge with sufficient range to measure overallpressure.• Restore the electric power suply (see § 7.3, page 52).• Bring the machine against a wall to block the travel movement.• Request a travel movement and measure overall pressure on the pressuregauge.• Adjust the hexagonal hollow head screw on the overall pressure limiter (1) sothat movements are disabled at the pressure indicated in the table below.• Put the machine in the maintenance configuration (see § 7.2, page 51).• Cut off the electric power supply (see § 7.3, page 52).• Unscrew the pressure gauge and put the cap back on the hydraulic pressuretap.• Put the machine back in the operational configuration.• Make several travel movements to check that the machine works properly.Compact22 - Adjusting the steering pressure limiter (2)• Put the machine in the low configuration.• Cut off the electric power supply (see § 7.3, page 52).• Unscrew the cap of the hydraulic pressure tap marked «MX» on the hydraulicblock and connect a pressure gauge with sufficient range to measure thesteering pressure.• Restore the electric power supply (see § 7.3, page 52).• Activate the steering command as far as possible to the right or left.• Maintain the steering command and measure the steering pressure on thepressure gauge.13NB:Steering is disabled after a certain period when at the maximum in onedirection, and only the other direction is possible and can re-authorisesteering in the initial direction. The steering pressure measurement timeis therefore limited.Optimum2• If necessary, adjust the hexagonal hollow head screw on the steering pressurelimiter (2) to disable movement at the pressure indicated in the tablebelow.• Put the machine in the maintenance configuration (see § 7.2, page 51).• Cut off the electric power supply (see § 7.3, page 52).• Unscrew the pressure gauge and put the cap back on the hydraulic pressuretap.• Put the machine back in the operational configuration.• Make several steering movements to check that the machine works properly.