- Page 1:

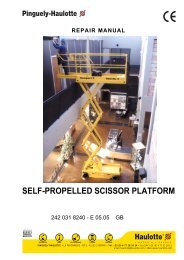

REPAIR MANUALSELF-PROPELLED SCISSOR

- Page 6:

21 Repair manual

- Page 9 and 10:

Repair Manual10 - CORRECTIVE MAINTE

- Page 11 and 12:

Repair manual 31 - GENERAL RECOMMEN

- Page 13 and 14:

Repair manual 3To avoid all risk of

- Page 15 and 16:

Repair manual 3NB:In the case of re

- Page 17 and 18:

Repair manual 32 - SPECIFICATIONSel

- Page 19 and 20:

78590Repair manual 32.2 - SIZE2.2.1

- Page 21 and 22:

Repair manual 32.4 - PRESSURE TABLE

- Page 23 and 24:

Repair manual 33 - WIRING DIAGRAM17

- Page 25 and 26:

Repair manual 33.1.1 - Electric com

- Page 27 and 28:

Repair manual 33.2.1 - Electric com

- Page 29 and 30:

Repair manual 34 - ELECTRIC COMPONE

- Page 31 and 32:

Repair manual 34.4 - END OF TRAVEL

- Page 33 and 34:

Repair manual 34.7 - USING THE ON-B

- Page 35 and 36:

Repair manual 35 - HYDRAULIC DIAGRA

- Page 37 and 38:

Repair manual 35.2.1 - Components l

- Page 39 and 40:

Repair manual 36 - DESCRIPTION OF T

- Page 41 and 42:

Repair manual 36.2 - MK4 HYDRAULIC

- Page 43 and 44:

Repair manual 3FRONT VIEW37

- Page 45 and 46:

Repair manual 36.2.1 - List of comp

- Page 47 and 48:

Repair manual 36.3.4 - Speed select

- Page 49 and 50:

Repair manual 3LoweringPotholes’

- Page 51 and 52:

Repair manual 37 - MAINTENANCE7.1 -

- Page 53 and 54:

Repair manual 37.4.2 - Maintenance

- Page 55 and 56:

Repair manual 3REMINDER:All these f

- Page 57 and 58:

Repair manual 38 - PREVENTIVE MAINT

- Page 59 and 60:

SHEET P001PREVENTIVE MAINTENANCE SH

- Page 61 and 62:

SHEET P002PREVENTIVE MAINTENANCE SH

- Page 63 and 64:

SHEET P003PREVENTIVE MAINTENANCE SH

- Page 65 and 66:

SHEET P004PREVENTIVE MAINTENANCE SH

- Page 67 and 68:

Repair manual 39 - OPERATING INCIDE

- Page 69 and 70:

Repair manual 39.1.3 - Travel syste

- Page 71 and 72:

Repair manual 3AlarmcodeNumberoffla

- Page 73 and 74:

Repair manual 39.2 - FAILURE DETECT

- Page 75 and 76:

SHEET DP001FAILURE DETECTION FLOW C

- Page 77 and 78:

SHEET DP002FAILURE DETECTION FLOW C

- Page 79 and 80:

SHEET DP003FAILURE DETECTION FLOW C

- Page 81 and 82: SHEET DP003FAILURE DETECTION FLOW C

- Page 83 and 84: SHEET DP004FAILURE DETECTION FLOW C

- Page 85 and 86: SHEET DP007FAILURE DETECTION FLOW C

- Page 87 and 88: SHEET DP007FAILURE DETECTION FLOW C

- Page 89 and 90: SHEET DP008FAILURE DETECTION FLOW C

- Page 91 and 92: SHEET DP009FAILURE DETECTION FLOW C

- Page 93 and 94: SHEET DP010FAILURE DETECTION FLOW C

- Page 95 and 96: SHEET DP011FAILURE DETECTION FLOW C

- Page 97 and 98: SHEET DP012FAILURE DETECTION FLOW C

- Page 99 and 100: SHEET DP013FAILURE DETECTION FLOW C

- Page 101 and 102: FAILURE DETECTION FLOW CHARTSHEET D

- Page 103 and 104: FAILURE DETECTION FLOW CHARTSHEET D

- Page 105 and 106: SHEET DP061FAILURE DETECTION FLOW C

- Page 107 and 108: SHEET DP062FAILURE DETECTION FLOW C

- Page 109 and 110: SHEET DP062FAILURE DETECTION FLOW C

- Page 111 and 112: Repair manual10 - CORRECTIVE MAINTE

- Page 113 and 114: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 115 and 116: SHEET C002CORRECTIVE MAINTENANCE SH

- Page 117 and 118: SHEET C003CORRECTIVE MAINTENANCE SH

- Page 119 and 120: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 121 and 122: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 123 and 124: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 125 and 126: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 127 and 128: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 129 and 130: CORRECTIVE MAINTENANCE SHEETSHEET C

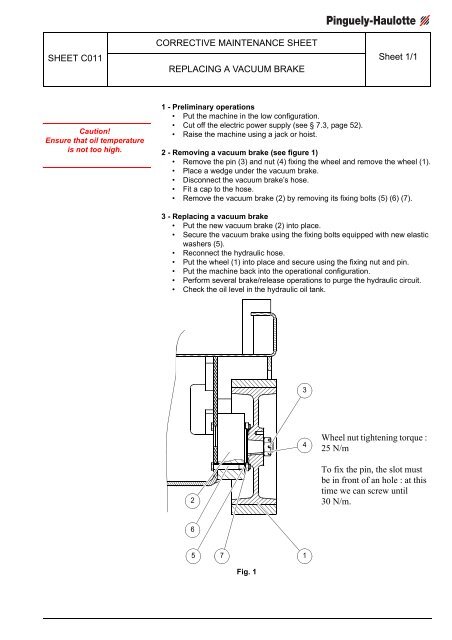

- Page 131: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 135 and 136: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 137 and 138: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 139 and 140: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 141 and 142: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 143 and 144: SHEET C017CORRECTIVE MAINTENANCE SH

- Page 145 and 146: CORRECTIVE MAINTENANCE SHEETSHEET C

- Page 147 and 148: SHEET C019CORRECTIVE MAINTENANCE SH

- Page 149 and 150: SHEET C020CORRECTIVE MAINTENANCE SH

- Page 151 and 152: SHEET C021CORRECTIVE MAINTENANCE SH

- Page 153 and 154: SHEET C022CORRECTIVE MAINTENANCE SH

- Page 155 and 156: SHEET C023CORRECTIVE MAINTENANCE SH

- Page 157 and 158: SHEET C024CORRECTIVE MAINTENANCE SH

- Page 159 and 160: SHEET C025CORRECTIVE MAINTENANCE SH

- Page 161 and 162: SHEET C026CORRECTIVE MAINTENANCE SH

- Page 163 and 164: SHEET C027CORRECTIVE MAINTENANCE SH

- Page 165 and 166: SHEET C028CORRECTIVE MAINTENANCE SH

- Page 167 and 168: SHEET C029CORRECTIVE MAINTENANCE SH

- Page 169 and 170: SHEET C030CORRECTIVE MAINTENANCE SH

- Page 171 and 172: SHEET C031CORRECTIVE MAINTENANCE SH

- Page 173 and 174: SHEET C032CORRECTIVE MAINTENANCE SH

- Page 175: 2CORRECTIVE MAINTENANCE SHEETSHEET