23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

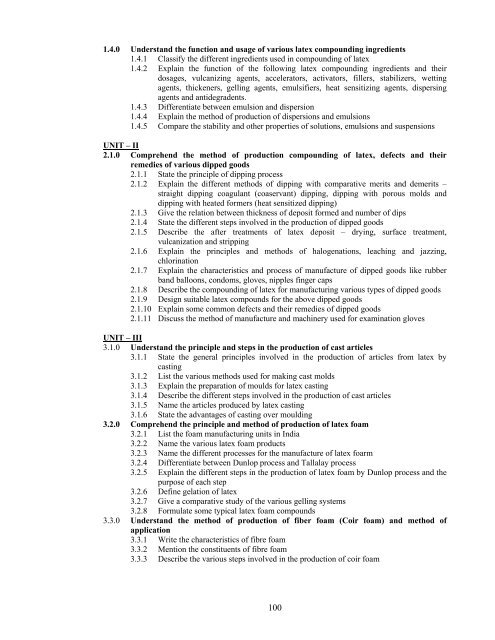

1.4.0 Understand the function and usage of various latex compounding ingredients1.4.1 Classify the different ingredients used in compounding of latex1.4.2 Explain the function of the following latex compounding ingredients and theirdosages, vulcanizing agents, accelerators, activators, fillers, stabilizers, wettingagents, thickeners, gelling agents, emulsifiers, heat sensitizing agents, dispersingagents and antidegradents.1.4.3 Differentiate between emulsion and dispersion1.4.4 Explain the method of production of dispersions and emulsions1.4.5 Compare the stability and other properties of solutions, emulsions and suspensionsUNIT – II2.1.0 Comprehend the method of production compounding of latex, defects and theirremedies of various dipped goods2.1.1 State the principle of dipping process2.1.2 Explain the different methods of dipping with comparative merits and demerits –straight dipping coagulant (coaservant) dipping, dipping with porous molds anddipping with heated formers (heat sensitized dipping)2.1.3 Give the relation between thickness of deposit formed and number of dips2.1.4 State the different steps involved in the production of dipped goods2.1.5 Describe the after treatments of latex deposit – drying, surface treatment,vulcanization and stripping2.1.6 Explain the principles and methods of halogenations, leaching and jazzing,chlorination2.1.7 Explain the characteristics and process of manufacture of dipped goods like rubberband balloons, condoms, gloves, nipples finger caps2.1.8 Describe the compounding of latex for manufacturing various types of dipped goods2.1.9 Design suitable latex compounds for the above dipped goods2.1.10 Explain some common defects and their remedies of dipped goods2.1.11 Discuss the method of manufacture and machinery used for examination glovesUNIT – III3.1.0 Understand the principle and steps in the production of cast articles3.1.1 State the general principles involved in the production of articles from latex bycasting3.1.2 List the various methods used for making cast molds3.1.3 Explain the preparation of moulds for latex casting3.1.4 Describe the different steps involved in the production of cast articles3.1.5 Name the articles produced by latex casting3.1.6 State the advantages of casting over moulding3.2.0 Comprehend the principle and method of production of latex foam3.2.1 List the foam manufacturing units in India3.2.2 Name the various latex foam products3.2.3 Name the different processes for the manufacture of latex foarm3.2.4 Differentiate between Dunlop process and Tallalay process3.2.5 Explain the different steps in the production of latex foam by Dunlop process and thepurpose of each step3.2.6 Define gelation of latex3.2.7 Give a comparative study of the various gelling systems3.2.8 Formulate some typical latex foam compounds3.3.0 Understand the method of production of fiber foam (Coir foam) and method ofapplication3.3.1 Write the characteristics of fibre foam3.3.2 Mention the constituents of fibre foam3.3.3 Describe the various steps involved in the production of coir foam100