23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

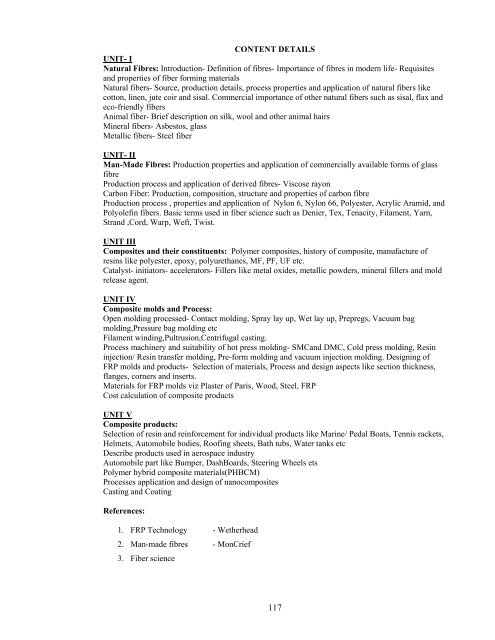

CONTENT DETAILSUNIT- INatural Fibres: Introduction- Definition of fibres- Importance of fibres in modern life- Requisitesand properties of fiber forming materialsNatural fibers- Source, production details, process properties and application of natural fibers likecotton, linen, jute coir and sisal. Commercial importance of other natural fibers such as sisal, flax andeco-friendly fibersAnimal fiber- Brief description on silk, wool and other animal hairsMineral fibers- Asbestos, glassMetallic fibers- Steel fiberUNIT- IIMan-Made Fibres: Production properties and application of commercially available forms of glassfibreProduction process and application of derived fibres- Viscose rayonCarbon Fiber: Production, composition, structure and properties of carbon fibreProduction process , properties and application of Nylon 6, Nylon 66, Polyester, Acrylic Aramid, andPolyolefin fibers. Basic terms used in fiber science such as Denier, Tex, Tenacity, Filament, Yarn,Strand ,Cord, Warp, Weft, Twist.UNIT IIIComposites and their constituents: Polymer composites, history of composite, manufacture ofresins like polyester, epoxy, polyurethanes, MF, PF, UF etc.Catalyst- initiators- accelerators- Fillers like metal oxides, metallic powders, mineral fillers and moldrelease agent.UNIT IVComposite molds and Process:Open molding processed- Contact molding, Spray lay up, Wet lay up, Prepregs, Vacuum bagmolding,Pressure bag molding etcFilament winding,Pultrusion,Centrifugal casting.Process machinery and suitability of hot press molding- SMCand DMC, Cold press molding, Resininjection/ Resin transfer molding, Pre-form molding and vacuum injection molding. Designing ofFRP molds and products- Selection of materials, Process and design aspects like section thickness,flanges, corners and inserts.Materials for FRP molds viz Plaster of Paris, Wood, Steel, FRPCost calculation of composite productsUNIT VComposite products:Selection of resin and reinforcement for individual products like Marine/ Pedal Boats, Tennis rackets,Helmets, Automobile bodies, Roofing sheets, Bath tubs, Water tanks etcDescribe products used in aerospace industryAutomobile part like Bumper, DashBoards, Steering Wheels etsPolymer hybrid composite materials(PHBCM)Processes application and design of nanocompositesCasting and CoatingReferences:1. FRP Technology - Wetherhead2. Man-made fibres - MonCrief3. Fiber science117