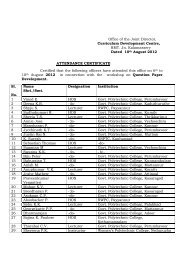

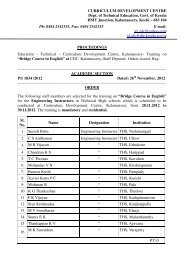

23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

23 - Curriculum Development Centre, Kalamassery

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

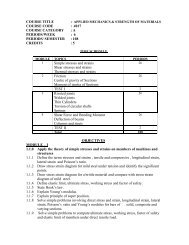

2.1.17 Explain the preparation, properties, structure and application of Nylon 6, Nylon 66,Polyester, Acrylic, Aramid and Poly olefin fibres.2.2.0 Understand the basic terms used in fibre science2.2.1 Define the terms denier, Tex, Tenacity, Filament, Yarn, Strand, Cord, Warp, Wefts,Twist etc.UNIT – III3.4.0 Understand various composites and their constituents3.4.1 Define polymer composites3.4.2 Describe briefly the history of polymer composites3.4.3 Describe briefly manufacture of resins like unsaturated poly ester, epoxy, PU,MF, PF etc with reference to their unique properties and suitability for use incomposite products.3.4.4 Describe the use of catalysts and initiators in the process of making composites withspecial attention to their function and properties (with suitable examples).3.4.5 Explain the function of accelerators with examples3.4.6 Compare the use of various fillers like Mineral, Metal oxide, metallic powderswith suitable examples3.1.7 Mention mould releasing agent3.1.8 Mention the advantage of Polypropylene as a resin matrix and a fibre3.1.9 Mention thermoplastic compositesUNIT – IV4.3.0 Understand different composite, molds and process4.3.1 Classify molding process into open and closed molding4.3.2 Describe the process, machinery and suitability of open molding process like Contactmolding, Spray layer, Hand lay up. Wet lay up, pre-preg, Vaccum bag molding,Pressure bag molding, RRIM etc4.3.3 Describe the process and suitability of Filament winding, Pultrusion and Centrifugalcasting in composite products4.3.4 Explain the process ,machinery and suitability of Hot press molding – SMC andDMC, Cold press molding, Resin injection/transfer molding, Preform Molding andVacuum injection molding4.4.0 Understand designing of FRP molds and products4.4.1 Describe selection of materials, process and design aspects like section thickness,flanges, corners and inserts4.4.2 List the materials for FRP molds like POP, Wood, Steel, FRP etc4.4.3 Explain method of cost calculation of composite productsUNIT – V5.1.0 Understand the manufacture of composite products5.1.1 Explain the manufacture of following products and justify selection of resin andreinforcement: Marine/ Pedal Boats, Tennis rackets, Helmets, Automobile bodies,Roofing sheets, Bath tubs, Water tanks etc5.1.2 Describe the various products used in aerospace industry5.1.3 List the various composite parts used in automobiles(Bumper, Dashboard, Steeringwheels etc)5.2.0 List out the various polymer hybrid composite materials(PHBCM) and their production5.3.0 Understand the process, application and design of casting and coatings.5.4.0 Knowledge of nanocomposite materials116