Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

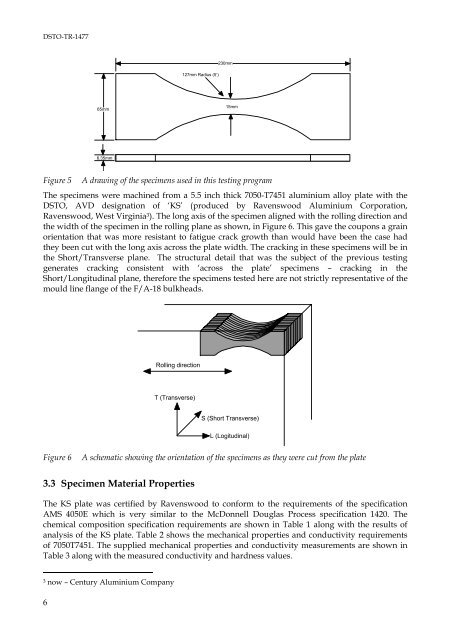

DSTO-TR-1477127mm Radius (5’)230mm65mm15mm6.35mmFigure 5A draw<strong>in</strong>g of the specimens used <strong>in</strong> this test<strong>in</strong>g programThe specimens were mach<strong>in</strong>ed from a 5.5 <strong>in</strong>ch thick 7050-T7451 alum<strong>in</strong>ium alloy plate with theDSTO, AVD designation of ‘KS’ (produced by Ravenswood Alum<strong>in</strong>ium Corporation,Ravenswood, West Virg<strong>in</strong>ia 3 ). The long axis of the specimen aligned with the roll<strong>in</strong>g direction andthe width of the specimen <strong>in</strong> the roll<strong>in</strong>g plane as shown, <strong>in</strong> Figure 6. This gave the coupons a gra<strong>in</strong>orientation that was more resistant to fatigue crack growth than would have been the case hadthey been cut with the long axis across the plate width. The crack<strong>in</strong>g <strong>in</strong> these specimens will be <strong>in</strong>the Short/Transverse plane. The structural detail that was the subject of the previous test<strong>in</strong>ggenerates crack<strong>in</strong>g consistent with ‘across the plate’ specimens – crack<strong>in</strong>g <strong>in</strong> theShort/Longitud<strong>in</strong>al plane, therefore the specimens tested here are not strictly representative of themould l<strong>in</strong>e flange of the F/A-18 bulkheads.Roll<strong>in</strong>g directionT (Transverse)S (Short Transverse)L (Logitud<strong>in</strong>al)Figure 6A schematic show<strong>in</strong>g the orientation of the specimens as they were cut from the plate3.3 Specimen Material PropertiesThe KS plate was certified by Ravenswood to conform to the requirements of the specificationAMS 4050E which is very similar to the McDonnell Douglas Process specification 1420. Thechemical composition specification requirements are shown <strong>in</strong> Table 1 along with the results ofanalysis of the KS plate. Table 2 shows the mechanical properties and conductivity requirementsof <strong>7050T7451</strong>. The supplied mechanical properties and conductivity measurements are shown <strong>in</strong>Table 3 along with the measured conductivity and hardness values.3 now – Century Alum<strong>in</strong>ium Company6