Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

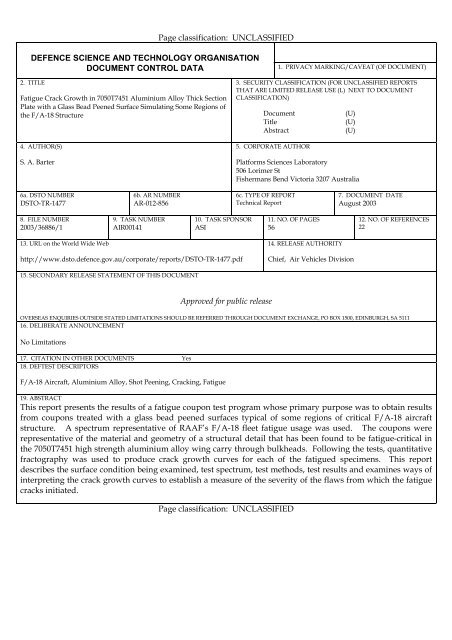

Page classification: UNCLASSIFIEDDEFENCE SCIENCE AND TECHNOLOGY ORGANISATIONDOCUMENT CONTROL DATA1. PRIVACY MARKING/CAVEAT (OF DOCUMENT)2. TITLE<strong>Fatigue</strong> <strong>Crack</strong> <strong>Growth</strong> <strong>in</strong> <strong>7050T7451</strong> Alum<strong>in</strong>ium <strong>Alloy</strong> <strong>Thick</strong> <strong>Section</strong>Plate with a Glass Bead Peened Surface Simulat<strong>in</strong>g Some Regions ofthe F/A-18 Structure4. AUTHOR(S)S. A. Barter3. SECURITY CLASSIFICATION (FOR UNCLASSIFIED REPORTSTHAT ARE LIMITED RELEASE USE (L) NEXT TO DOCUMENTCLASSIFICATION)DocumentTitleAbstract5. CORPORATE AUTHOR(U)(U)(U)Platforms Sciences Laboratory506 Lorimer StFishermans Bend Victoria 3207 Australia6a. DSTO NUMBERDSTO-TR-14776b. AR NUMBERAR-012-8566c. TYPE OF REPORTTechnical Report7. DOCUMENT DATEAugust 20038. FILE NUMBER2003/36886/19. TASK NUMBERAIR0014110. TASK SPONSORASI11. NO. OF PAGES5612. NO. OF REFERENCES2213. URL on the World Wide Web14. RELEASE AUTHORITYhttp://www.dsto.defence.gov.au/corporate/reports/DSTO-TR-1477.pdfChief, Air Vehicles Division15. SECONDARY RELEASE STATEMENT OF THIS DOCUMENTApproved for public releaseOVERSEAS ENQUIRIES OUTSIDE STATED LIMITATIONS SHOULD BE REFERRED THROUGH DOCUMENT EXCHANGE, PO BOX 1500, EDINBURGH, SA 511116. DELIBERATE ANNOUNCEMENTNo Limitations17. CITATION IN OTHER DOCUMENTS Yes18. DEFTEST DESCRIPTORSF/A-18 Aircraft, Alum<strong>in</strong>ium <strong>Alloy</strong>, Shot Peen<strong>in</strong>g, <strong>Crack</strong><strong>in</strong>g, <strong>Fatigue</strong>19. ABSTRACTThis report presents the results of a fatigue coupon test program whose primary purpose was to obta<strong>in</strong> resultsfrom coupons treated with a glass bead peened surfaces typical of some regions of critical F/A-18 aircraftstructure. A spectrum representative of RAAF’s F/A-18 fleet fatigue usage was used. The coupons wererepresentative of the material and geometry of a structural detail that has been found to be fatigue-critical <strong>in</strong>the <strong>7050T7451</strong> high strength alum<strong>in</strong>ium alloy w<strong>in</strong>g carry through bulkheads. Follow<strong>in</strong>g the tests, quantitativefractography was used to produce crack growth curves for each of the fatigued specimens. This reportdescribes the surface condition be<strong>in</strong>g exam<strong>in</strong>ed, test spectrum, test methods, test results and exam<strong>in</strong>es ways of<strong>in</strong>terpret<strong>in</strong>g the crack growth curves to establish a measure of the severity of the flaws from which the fatiguecracks <strong>in</strong>itiated.Page classification: UNCLASSIFIED