Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Fatigue Crack Growth in 7050T7451 Aluminium Alloy Thick Section ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

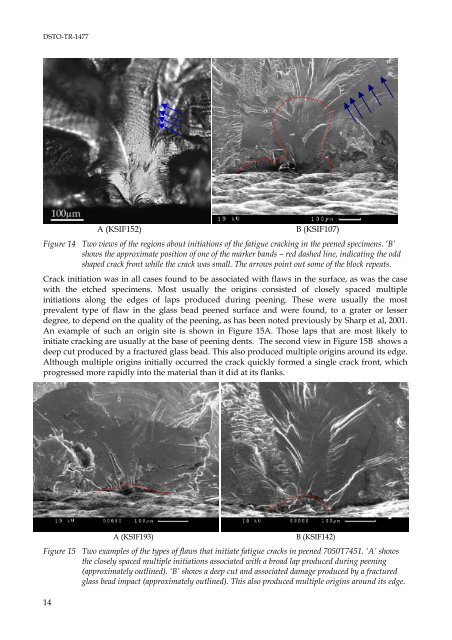

DSTO-TR-1477A (KSIF152)B (KSIF107)Figure 14 Two views of the regions about <strong>in</strong>itiations of the fatigue crack<strong>in</strong>g <strong>in</strong> the peened specimens. ‘B’shows the approximate position of one of the marker bands – red dashed l<strong>in</strong>e, <strong>in</strong>dicat<strong>in</strong>g the oddshaped crack front while the crack was small. The arrows po<strong>in</strong>t out some of the block repeats.<strong>Crack</strong> <strong>in</strong>itiation was <strong>in</strong> all cases found to be associated with flaws <strong>in</strong> the surface, as was the casewith the etched specimens. Most usually the orig<strong>in</strong>s consisted of closely spaced multiple<strong>in</strong>itiations along the edges of laps produced dur<strong>in</strong>g peen<strong>in</strong>g. These were usually the mostprevalent type of flaw <strong>in</strong> the glass bead peened surface and were found, to a grater or lesserdegree, to depend on the quality of the peen<strong>in</strong>g, as has been noted previously by Sharp et al, 2001.An example of such an orig<strong>in</strong> site is shown <strong>in</strong> Figure 15A. Those laps that are most likely to<strong>in</strong>itiate crack<strong>in</strong>g are usually at the base of peen<strong>in</strong>g dents. The second view <strong>in</strong> Figure 15B shows adeep cut produced by a fractured glass bead. This also produced multiple orig<strong>in</strong>s around its edge.Although multiple orig<strong>in</strong>s <strong>in</strong>itially occurred the crack quickly formed a s<strong>in</strong>gle crack front, whichprogressed more rapidly <strong>in</strong>to the material than it did at its flanks.14A (KSIF193)B (KSIF142)Figure 15 Two examples of the types of flaws that <strong>in</strong>itiate fatigue cracks <strong>in</strong> peened <strong>7050T7451</strong>. ‘A’ showsthe closely spaced multiple <strong>in</strong>itiations associated with a broad lap produced dur<strong>in</strong>g peen<strong>in</strong>g(approximately outl<strong>in</strong>ed). ‘B’ shows a deep cut and associated damage produced by a fracturedglass bead impact (approximately outl<strong>in</strong>ed). This also produced multiple orig<strong>in</strong>s around its edge.