Strategic Guidance on the Management of LLW and ILW / LLW ...

Strategic Guidance on the Management of LLW and ILW / LLW ...

Strategic Guidance on the Management of LLW and ILW / LLW ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

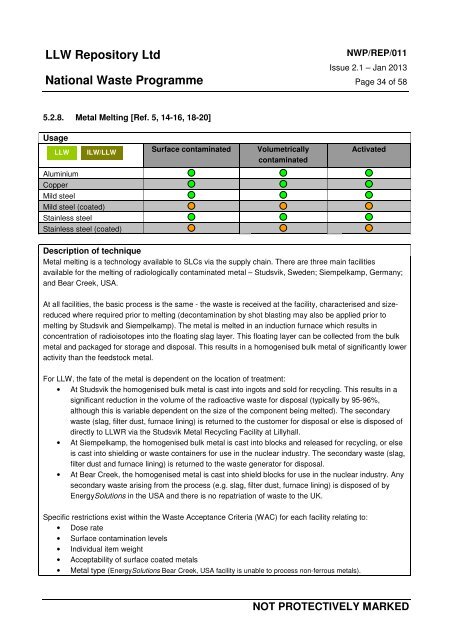

<strong>LLW</strong> Repository LtdNati<strong>on</strong>al Waste ProgrammeNWP/REP/011Issue 2.1 – Jan 2013Page 34 <strong>of</strong> 585.2.8. Metal Melting [Ref. 5, 14-16, 18-20]Usage<strong>LLW</strong><strong>ILW</strong>/<strong>LLW</strong>Surface c<strong>on</strong>taminatedVolumetricallyc<strong>on</strong>taminatedActivatedAluminiumCopperMild steelMild steel (coated)Stainless steelStainless steel (coated)Descripti<strong>on</strong> <strong>of</strong> techniqueMetal melting is a technology available to SLCs via <strong>the</strong> supply chain. There are three main facilitiesavailable for <strong>the</strong> melting <strong>of</strong> radiologically c<strong>on</strong>taminated metal – Studsvik, Sweden; Siempelkamp, Germany;<strong>and</strong> Bear Creek, USA.At all facilities, <strong>the</strong> basic process is <strong>the</strong> same - <strong>the</strong> waste is received at <strong>the</strong> facility, characterised <strong>and</strong> sizereducedwhere required prior to melting (dec<strong>on</strong>taminati<strong>on</strong> by shot blasting may also be applied prior tomelting by Studsvik <strong>and</strong> Siempelkamp). The metal is melted in an inducti<strong>on</strong> furnace which results inc<strong>on</strong>centrati<strong>on</strong> <strong>of</strong> radioisotopes into <strong>the</strong> floating slag layer. This floating layer can be collected from <strong>the</strong> bulkmetal <strong>and</strong> packaged for storage <strong>and</strong> disposal. This results in a homogenised bulk metal <strong>of</strong> significantly loweractivity than <strong>the</strong> feedstock metal.For <strong>LLW</strong>, <strong>the</strong> fate <strong>of</strong> <strong>the</strong> metal is dependent <strong>on</strong> <strong>the</strong> locati<strong>on</strong> <strong>of</strong> treatment:• At Studsvik <strong>the</strong> homogenised bulk metal is cast into ingots <strong>and</strong> sold for recycling. This results in asignificant reducti<strong>on</strong> in <strong>the</strong> volume <strong>of</strong> <strong>the</strong> radioactive waste for disposal (typically by 95-96%,although this is variable dependent <strong>on</strong> <strong>the</strong> size <strong>of</strong> <strong>the</strong> comp<strong>on</strong>ent being melted). The sec<strong>on</strong>darywaste (slag, filter dust, furnace lining) is returned to <strong>the</strong> customer for disposal or else is disposed <strong>of</strong>directly to <strong>LLW</strong>R via <strong>the</strong> Studsvik Metal Recycling Facility at Lillyhall.• At Siempelkamp, <strong>the</strong> homogenised bulk metal is cast into blocks <strong>and</strong> released for recycling, or elseis cast into shielding or waste c<strong>on</strong>tainers for use in <strong>the</strong> nuclear industry. The sec<strong>on</strong>dary waste (slag,filter dust <strong>and</strong> furnace lining) is returned to <strong>the</strong> waste generator for disposal.• At Bear Creek, <strong>the</strong> homogenised metal is cast into shield blocks for use in <strong>the</strong> nuclear industry. Anysec<strong>on</strong>dary waste arising from <strong>the</strong> process (e.g. slag, filter dust, furnace lining) is disposed <strong>of</strong> byEnergySoluti<strong>on</strong>s in <strong>the</strong> USA <strong>and</strong> <strong>the</strong>re is no repatriati<strong>on</strong> <strong>of</strong> waste to <strong>the</strong> UK.Specific restricti<strong>on</strong>s exist within <strong>the</strong> Waste Acceptance Criteria (WAC) for each facility relating to:• Dose rate• Surface c<strong>on</strong>taminati<strong>on</strong> levels• Individual item weight• Acceptability <strong>of</strong> surface coated metalsA company • owned Metal by UK type Nuclear (EnergySoluti<strong>on</strong>s Waste <strong>Management</strong> Bear Ltd Creek, USA facility is unable to process n<strong>on</strong>-ferrous metals).NOT PROTECTIVELY MARKED