Strategic Guidance on the Management of LLW and ILW / LLW ...

Strategic Guidance on the Management of LLW and ILW / LLW ...

Strategic Guidance on the Management of LLW and ILW / LLW ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

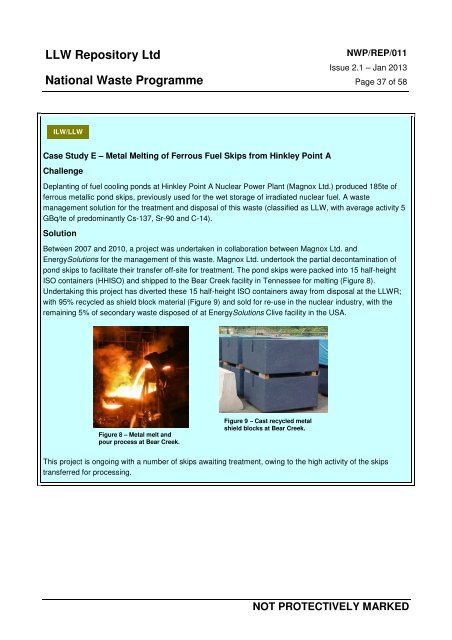

<strong>LLW</strong> Repository LtdNati<strong>on</strong>al Waste ProgrammeNWP/REP/011Issue 2.1 – Jan 2013Page 37 <strong>of</strong> 58<strong>ILW</strong>/<strong>LLW</strong>Case Study E – Metal Melting <strong>of</strong> Ferrous Fuel Skips from Hinkley Point AChallengeDeplanting <strong>of</strong> fuel cooling p<strong>on</strong>ds at Hinkley Point A Nuclear Power Plant (Magnox Ltd.) produced 185te <strong>of</strong>ferrous metallic p<strong>on</strong>d skips, previously used for <strong>the</strong> wet storage <strong>of</strong> irradiated nuclear fuel. A wastemanagement soluti<strong>on</strong> for <strong>the</strong> treatment <strong>and</strong> disposal <strong>of</strong> this waste (classified as <strong>LLW</strong>, with average activity 5GBq/te <strong>of</strong> predominantly Cs-137, Sr-90 <strong>and</strong> C-14).Soluti<strong>on</strong>Between 2007 <strong>and</strong> 2010, a project was undertaken in collaborati<strong>on</strong> between Magnox Ltd. <strong>and</strong>EnergySoluti<strong>on</strong>s for <strong>the</strong> management <strong>of</strong> this waste. Magnox Ltd. undertook <strong>the</strong> partial dec<strong>on</strong>taminati<strong>on</strong> <strong>of</strong>p<strong>on</strong>d skips to facilitate <strong>the</strong>ir transfer <strong>of</strong>f-site for treatment. The p<strong>on</strong>d skips were packed into 15 half-heightISO c<strong>on</strong>tainers (HHISO) <strong>and</strong> shipped to <strong>the</strong> Bear Creek facility in Tennessee for melting (Figure 8).Undertaking this project has diverted <strong>the</strong>se 15 half-height ISO c<strong>on</strong>tainers away from disposal at <strong>the</strong> <strong>LLW</strong>R;with 95% recycled as shield block material (Figure 9) <strong>and</strong> sold for re-use in <strong>the</strong> nuclear industry, with <strong>the</strong>remaining 5% <strong>of</strong> sec<strong>on</strong>dary waste disposed <strong>of</strong> at EnergySoluti<strong>on</strong>s Clive facility in <strong>the</strong> USA.Figure 8 – Metal melt <strong>and</strong>pour process at Bear Creek.Figure 9 – Cast recycled metalshield blocks at Bear Creek.This project is <strong>on</strong>going with a number <strong>of</strong> skips awaiting treatment, owing to <strong>the</strong> high activity <strong>of</strong> <strong>the</strong> skipstransferred for processing.A company owned by UK Nuclear Waste <strong>Management</strong> LtdNOT PROTECTIVELY MARKED