100% Positive Material Identification

23mhiW2

23mhiW2

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Understanding Implants in Knee and Hip Replacement (continued)<br />

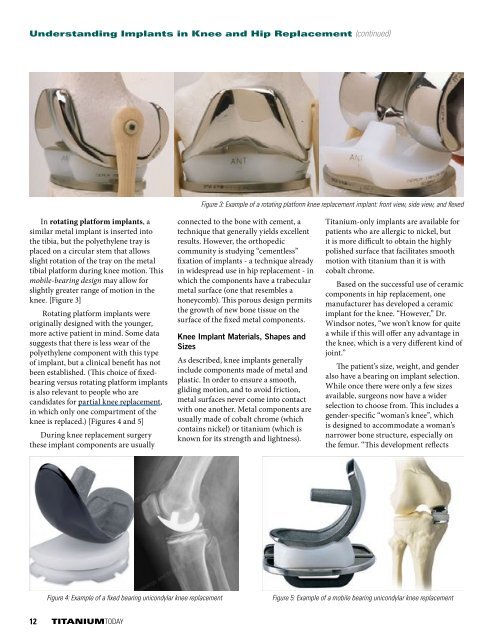

Figure 3: Example of a rotating platform knee replacement implant: front view, side view, and flexed<br />

In rotating platform implants, a<br />

similar metal implant is inserted into<br />

the tibia, but the polyethylene tray is<br />

placed on a circular stem that allows<br />

slight rotation of the tray on the metal<br />

tibial platform during knee motion. This<br />

mobile-bearing design may allow for<br />

slightly greater range of motion in the<br />

knee. [Figure 3]<br />

Rotating platform implants were<br />

originally designed with the younger,<br />

more active patient in mind. Some data<br />

suggests that there is less wear of the<br />

polyethylene component with this type<br />

of implant, but a clinical benefit has not<br />

been established. (This choice of fixedbearing<br />

versus rotating platform implants<br />

is also relevant to people who are<br />

candidates for partial knee replacement,<br />

in which only one compartment of the<br />

knee is replaced.) [Figures 4 and 5]<br />

During knee replacement surgery<br />

these implant components are usually<br />

connected to the bone with cement, a<br />

technique that generally yields excellent<br />

results. However, the orthopedic<br />

community is studying “cementless”<br />

fixation of implants - a technique already<br />

in widespread use in hip replacement - in<br />

which the components have a trabecular<br />

metal surface (one that resembles a<br />

honeycomb). This porous design permits<br />

the growth of new bone tissue on the<br />

surface of the fixed metal components.<br />

Knee Implant <strong>Material</strong>s, Shapes and<br />

Sizes<br />

As described, knee implants generally<br />

include components made of metal and<br />

plastic. In order to ensure a smooth,<br />

gliding motion, and to avoid friction,<br />

metal surfaces never come into contact<br />

with one another. Metal components are<br />

usually made of cobalt chrome (which<br />

contains nickel) or titanium (which is<br />

known for its strength and lightness).<br />

Titanium-only implants are available for<br />

patients who are allergic to nickel, but<br />

it is more difficult to obtain the highly<br />

polished surface that facilitates smooth<br />

motion with titanium than it is with<br />

cobalt chrome.<br />

Based on the successful use of ceramic<br />

components in hip replacement, one<br />

manufacturer has developed a ceramic<br />

implant for the knee. “However,” Dr.<br />

Windsor notes, “we won’t know for quite<br />

a while if this will offer any advantage in<br />

the knee, which is a very different kind of<br />

joint.”<br />

The patient’s size, weight, and gender<br />

also have a bearing on implant selection.<br />

While once there were only a few sizes<br />

available, surgeons now have a wider<br />

selection to choose from. This includes a<br />

gender-specific “woman’s knee”, which<br />

is designed to accommodate a woman’s<br />

narrower bone structure, especially on<br />

the femur. “This development reflects<br />

Figure 4: Example of a fixed bearing unicondylar knee replacement<br />

Figure 5: Example of a mobile bearing unicondylar knee replacement<br />

12 TITANIUMTODAY