100% Positive Material Identification

23mhiW2

23mhiW2

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

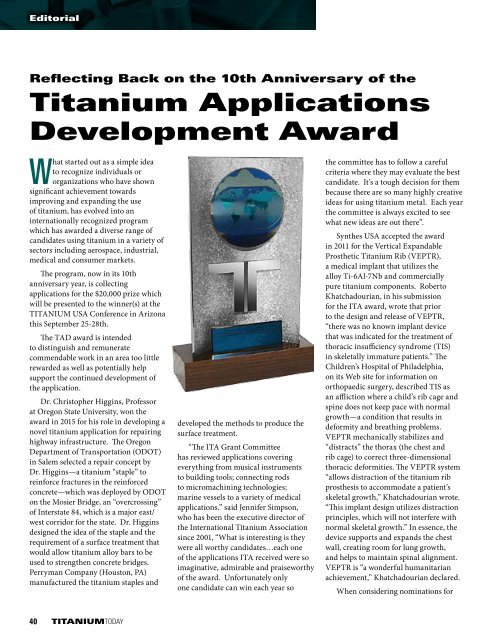

Editorial<br />

Reflecting Back on the 10th Anniversary of the<br />

Titanium Applications<br />

Development Award<br />

What started out as a simple idea<br />

to recognize individuals or<br />

organizations who have shown<br />

significant achievement towards<br />

improving and expanding the use<br />

of titanium, has evolved into an<br />

internationally recognized program<br />

which has awarded a diverse range of<br />

candidates using titanium in a variety of<br />

sectors including aerospace, industrial,<br />

medical and consumer markets.<br />

The program, now in its 10th<br />

anniversary year, is collecting<br />

applications for the $20,000 prize which<br />

will be presented to the winner(s) at the<br />

TITANIUM USA Conference in Arizona<br />

this September 25-28th.<br />

The TAD award is intended<br />

to distinguish and remunerate<br />

commendable work in an area too little<br />

rewarded as well as potentially help<br />

support the continued development of<br />

the application.<br />

Dr. Christopher Higgins, Professor<br />

at Oregon State University, won the<br />

award in 2015 for his role in developing a<br />

novel titanium application for repairing<br />

highway infrastructure. The Oregon<br />

Department of Transportation (ODOT)<br />

in Salem selected a repair concept by<br />

Dr. Higgins—a titanium “staple” to<br />

reinforce fractures in the reinforced<br />

concrete—which was deployed by ODOT<br />

on the Mosier Bridge, an “overcrossing”<br />

of Interstate 84, which is a major east/<br />

west corridor for the state. Dr. Higgins<br />

designed the idea of the staple and the<br />

requirement of a surface treatment that<br />

would allow titanium alloy bars to be<br />

used to strengthen concrete bridges.<br />

Perryman Company (Houston, PA)<br />

manufactured the titanium staples and<br />

developed the methods to produce the<br />

surface treatment.<br />

“The ITA Grant Committee<br />

has reviewed applications covering<br />

everything from musical instruments<br />

to building tools; connecting rods<br />

to micromachining technologies;<br />

marine vessels to a variety of medical<br />

applications.” said Jennifer Simpson,<br />

who has been the executive director of<br />

the International Titanium Association<br />

since 2001, “What is interesting is they<br />

were all worthy candidates…each one<br />

of the applications ITA received were so<br />

imaginative, admirable and praiseworthy<br />

of the award. Unfortunately only<br />

one candidate can win each year so<br />

the committee has to follow a careful<br />

criteria where they may evaluate the best<br />

candidate. It’s a tough decision for them<br />

because there are so many highly creative<br />

ideas for using titanium metal. Each year<br />

the committee is always excited to see<br />

what new ideas are out there”.<br />

Synthes USA accepted the award<br />

in 2011 for the Vertical Expandable<br />

Prosthetic Titanium Rib (VEPTR),<br />

a medical implant that utilizes the<br />

alloy Ti-6Al-7Nb and commercially<br />

pure titanium components. Roberto<br />

Khatchadourian, in his submission<br />

for the ITA award, wrote that prior<br />

to the design and release of VEPTR,<br />

“there was no known implant device<br />

that was indicated for the treatment of<br />

thoracic insufficiency syndrome (TIS)<br />

in skeletally immature patients.” The<br />

Children’s Hospital of Philadelphia,<br />

on its Web site for information on<br />

orthopaedic surgery, described TIS as<br />

an affliction where a child’s rib cage and<br />

spine does not keep pace with normal<br />

growth—a condition that results in<br />

deformity and breathing problems.<br />

VEPTR mechanically stabilizes and<br />

“distracts” the thorax (the chest and<br />

rib cage) to correct three-dimensional<br />

thoracic deformities. The VEPTR system<br />

“allows distraction of the titanium rib<br />

prosthesis to accommodate a patient’s<br />

skeletal growth,” Khatchadourian wrote.<br />

“This implant design utilizes distraction<br />

principles, which will not interfere with<br />

normal skeletal growth.” In essence, the<br />

device supports and expands the chest<br />

wall, creating room for lung growth,<br />

and helps to maintain spinal alignment.<br />

VEPTR is “a wonderful humanitarian<br />

achievement,” Khatchadourian declared.<br />

When considering nominations for<br />

40 TITANIUMTODAY