Installation, Owner, and Diagnostic Manual IntelliPak® - Trane

Installation, Owner, and Diagnostic Manual IntelliPak® - Trane

Installation, Owner, and Diagnostic Manual IntelliPak® - Trane

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Skid Removal<br />

The unit ships on skids to provide forklift<br />

locations from the front or rear. The skid<br />

allows easy maneuverability of the unit<br />

during storage <strong>and</strong> transportation.<br />

Remove the skids before placing the unit<br />

in its permanent location.<br />

Remove the skids using a forklift or jack.<br />

Lift one end of the unit off of the skids.<br />

See Figure I-PC-5 <strong>and</strong> I-PC-6 on page 12<br />

for unit gravity block location. Slide the<br />

skids out <strong>and</strong> lower the unit at the<br />

installation location.<br />

Note: External isolation is not necessary<br />

since units are internally isolated. Consult a<br />

vibration specialist before “doubleisolating”<br />

the unit.<br />

External Unit Isolation<br />

If your job requires external vibration<br />

isolation, two options are available:<br />

isopads or spring-type isolators. Isopads<br />

should be placed under the unit at<br />

locations indicated on the factoryprovided<br />

isolator sheet.<br />

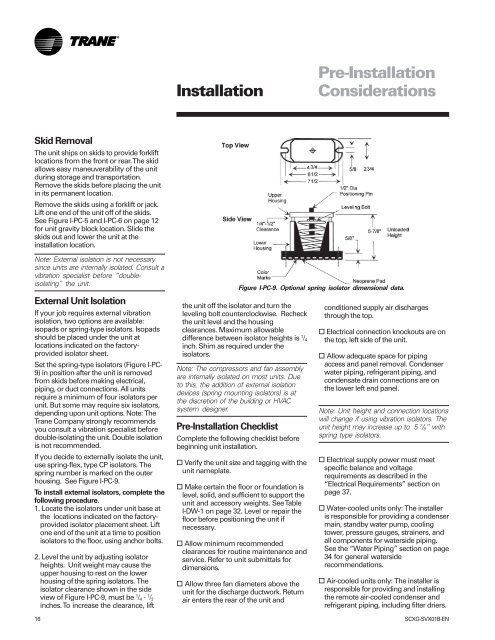

Set the spring-type isolators (Figure I-PC-<br />

9) in position after the unit is removed<br />

from skids before making electrical,<br />

piping, or duct connections. All units<br />

require a minimum of four isolators per<br />

unit. But some may require six isolators,<br />

depending upon unit options. Note: The<br />

<strong>Trane</strong> Company strongly recommends<br />

you consult a vibration specialist before<br />

double-isolating the unit. Double isolation<br />

is not recommended.<br />

If you decide to externally isolate the unit,<br />

use spring-flex, type CP isolators. The<br />

spring number is marked on the outer<br />

housing. See Figure I-PC-9.<br />

To install external isolators, complete the<br />

following procedure.<br />

1. Locate the isolators under unit base at<br />

the locations indicated on the factoryprovided<br />

isolator placement sheet. Lift<br />

one end of the unit at a time to position<br />

isolators to the floor, using anchor bolts.<br />

2. Level the unit by adjusting isolator<br />

heights. Unit weight may cause the<br />

upper housing to rest on the lower<br />

housing of the spring isolators. The<br />

isolator clearance shown in the side<br />

view of Figure I-PC-9, must be 1 /4 - 1 /2<br />

inches. To increase the clearance, lift<br />

<strong>Installation</strong><br />

the unit off the isolator <strong>and</strong> turn the<br />

leveling bolt counterclockwise. Recheck<br />

the unit level <strong>and</strong> the housing<br />

clearances. Maximum allowable<br />

difference between isolator heights is 1 /4<br />

inch. Shim as required under the<br />

isolators.<br />

Note: The compressors <strong>and</strong> fan assembly<br />

are internally isolated on most units. Due<br />

to this, the addition of external isolation<br />

devices (spring mounting isolators) is at<br />

the discretion of the building or HVAC<br />

system designer.<br />

Pre-<strong>Installation</strong> Checklist<br />

Complete the following checklist before<br />

beginning unit installation.<br />

o Verify the unit size <strong>and</strong> tagging with the<br />

unit nameplate.<br />

o Make certain the floor or foundation is<br />

level, solid, <strong>and</strong> sufficient to support the<br />

unit <strong>and</strong> accessory weights. See Table<br />

I-DW-1 on page 32. Level or repair the<br />

floor before positioning the unit if<br />

necessary.<br />

o Allow minimum recommended<br />

clearances for routine maintenance <strong>and</strong><br />

service. Refer to unit submittals for<br />

dimensions.<br />

o Allow three fan diameters above the<br />

unit for the discharge ductwork. Return<br />

air enters the rear of the unit <strong>and</strong><br />

Pre-<strong>Installation</strong><br />

Considerations<br />

Figure I-PC-9. Optional spring isolator dimensional data.<br />

conditioned supply air discharges<br />

through the top.<br />

o Electrical connection knockouts are on<br />

the top, left side of the unit.<br />

o Allow adequate space for piping<br />

access <strong>and</strong> panel removal. Condenser<br />

water piping, refrigerant piping, <strong>and</strong><br />

condensate drain connections are on<br />

the lower left end panel.<br />

Note: Unit height <strong>and</strong> connection locations<br />

will change if using vibration isolators. The<br />

unit height may increase up to 5 7 /8” with<br />

spring type isolators.<br />

o Electrical supply power must meet<br />

specific balance <strong>and</strong> voltage<br />

requirements as described in the<br />

“Electrical Requirements” section on<br />

page 37.<br />

o Water-cooled units only: The installer<br />

is responsible for providing a condenser<br />

main, st<strong>and</strong>by water pump, cooling<br />

tower, pressure gauges, strainers, <strong>and</strong><br />

all components for waterside piping.<br />

See the “Water Piping” section on page<br />

34 for general waterside<br />

recommendations.<br />

o Air-cooled units only: The installer is<br />

responsible for providing <strong>and</strong> installing<br />

the remote air-cooled condenser <strong>and</strong><br />

refrigerant piping, including filter driers.<br />

16 SCXG-SVX01B-EN