Powers Buyers Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

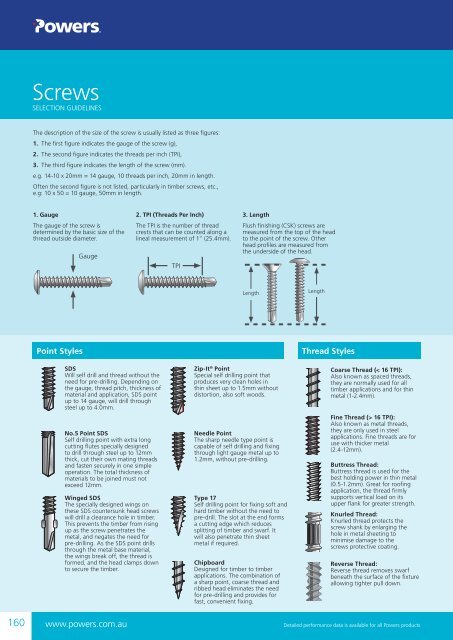

Screws<br />

SELECTION GUIDELINES<br />

The description of the size of the screw is usually listed as three figures:<br />

1. The first figure indicates the gauge of the screw (g),<br />

2. The second figure indicates the threads per inch (TPI),<br />

3. The third figure indicates the length of the screw (mm).<br />

e.g. 14-10 x 20mm = 14 gauge, 10 threads per inch, 20mm in length.<br />

Often the second figure is not listed, particularly in timber screws, etc.,<br />

e.g: 10 x 50 = 10 gauge, 50mm in length.<br />

1. Gauge<br />

The gauge of the screw is<br />

determined by the basic size of the<br />

thread outside diameter.<br />

Gauge<br />

2. TPI (Threads Per Inch)<br />

The TPI is the number of thread<br />

crests that can be counted along a<br />

lineal measurement of 1” (25.4mm).<br />

TPI<br />

3. Length<br />

Flush finishing (CSK) screws are<br />

measured from the top of the head<br />

to the point of the screw. Other<br />

head profiles are measured from<br />

the underside of the head.<br />

Length<br />

Length<br />

Point Styles<br />

SDS<br />

Will self drill and thread without the<br />

need for pre-drilling. Depending on<br />

the gauge, thread pitch, thickness of<br />

material and application, SDS point<br />

up to 14 gauge, will drill through<br />

steel up to 4.0mm.<br />

No.5 Point SDS<br />

Self drilling point with extra long<br />

cutting flutes specially designed<br />

to drill through steel up to 12mm<br />

thick, cut their own mating threads<br />

and fasten securely in one simple<br />

operation. The total thickness of<br />

materials to be joined must not<br />

exceed 12mm.<br />

Winged SDS<br />

The specially designed wings on<br />

these SDS countersunk head screws<br />

will drill a clearance hole in timber.<br />

This prevents the timber from rising<br />

up as the screw penetrates the<br />

metal, and negates the need for<br />

pre-drilling. As the SDS point drills<br />

through the metal base material,<br />

the wings break off, the thread is<br />

formed, and the head clamps down<br />

to secure the timber.<br />

Zip-It ® Point<br />

Special self drilling point that<br />

produces very clean holes in<br />

thin sheet up to 1.5mm without<br />

distortion, also soft woods.<br />

Needle Point<br />

The sharp needle type point is<br />

capable of self drilling and fixing<br />

through light gauge metal up to<br />

1.2mm, without pre-drilling.<br />

Type 17<br />

Self drilling point for fixing soft and<br />

hard timber without the need to<br />

pre-drill. The slot at the end forms<br />

a cutting edge which reduces<br />

splitting of timber and swarf. It<br />

will also penetrate thin sheet<br />

metal if required.<br />

Chipboard<br />

Designed for timber to timber<br />

applications. The combination of<br />

a sharp point, coarse thread and<br />

ribbed head eliminates the need<br />

for pre-drilling and provides for<br />

fast, convenient fixing.<br />

Thread Styles<br />

Coarse Thread (< 16 TPI):<br />

Also known as spaced threads,<br />

they are normally used for all<br />

timber applications and for thin<br />

metal (1-2.4mm).<br />

Fine Thread (> 16 TPI):<br />

Also known as metal threads,<br />

they are only used in steel<br />

applications. Fine threads are for<br />

use with thicker metal<br />

(2.4-12mm).<br />

Buttress Thread:<br />

Buttress thread is used for the<br />

best holding power in thin metal<br />

(0.5-1.2mm). Great for roofing<br />

application, the thread firmly<br />

supports vertical load on its<br />

upper flank for greater strength.<br />

Knurled Thread:<br />

Knurled thread protects the<br />

screw shank by enlarging the<br />

hole in metal sheeting to<br />

minimise damage to the<br />

screws protective coating.<br />

Reverse Thread:<br />

Reverse thread removes swarf<br />

beneath the surface of the fixture<br />

allowing tighter pull down.<br />

160 www.powers.com.au Detailed performance data is available for all <strong>Powers</strong> products