Powers Buyers Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

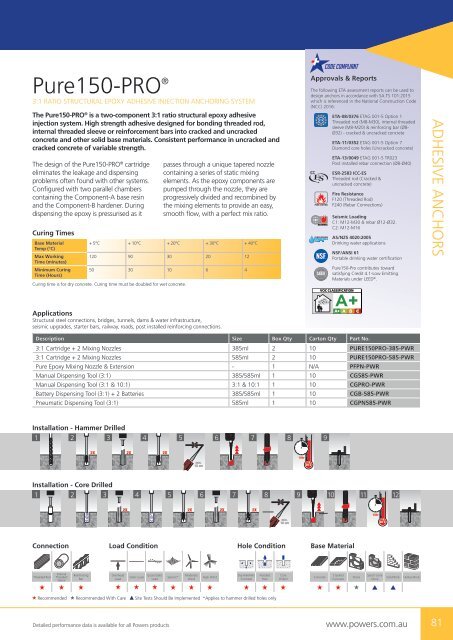

Pure150-PRO ®<br />

3:1 RATIO STRUCTURAL EPOXY ADHESIVE INJECTION ANCHORING SYSTEM<br />

The Pure150-PRO ® is a two-component 3:1 ratio structural epoxy adhesive<br />

injection system. High strength adhesive designed for bonding threaded rod,<br />

internal threaded sleeve or reinforcement bars into cracked and uncracked<br />

concrete and other solid base materials. Consistent performance in uncracked and<br />

cracked concrete of variable strength.<br />

The design of the Pure150-PRO ® cartridge<br />

eliminates the leakage and dispensing<br />

problems often found with other systems.<br />

Configured with two parallel chambers<br />

containing the Component-A base resin<br />

and the Component-B hardener. During<br />

dispensing the epoxy is pressurised as it<br />

Curing Times<br />

Base Material<br />

Temp (°C)<br />

Max Working<br />

Time (minutes)<br />

Minimum Curing<br />

Time (Hours)<br />

passes through a unique tapered nozzle<br />

containing a series of static mixing<br />

elements. As the epoxy components are<br />

pumped through the nozzle, they are<br />

progressively divided and recombined by<br />

the mixing elements to provide an easy,<br />

smooth flow, with a perfect mix ratio.<br />

+ 5°C + 10°C + 20°C + 30°C + 40°C<br />

120 90 30 20 12<br />

50 30 10 6 4<br />

Curing time is for dry concrete. Curing time must be doubled for wet concrete.<br />

Approvals & Reports<br />

The following ETA assessment reports can be used to<br />

design anchors in accordance with SA TS 101:2015<br />

which is referenced in the National Construction Code<br />

(NCC) 2016:<br />

FIRE RATED<br />

ETA-08/0376 ETAG 001-5 Option 1<br />

Threaded rod (M8-M30), internal threaded<br />

sleeve (M8-M20) & reinforcing bar (Ø8-<br />

Ø32) - cracked & uncracked concrete<br />

ETA-11/0352 ETAG 001-5 Option 7<br />

Diamond core holes (Uncracked concrete)<br />

ETA-13/0049 ETAG 001-5 TR023<br />

Post installed rebar connection (Ø8-Ø40)<br />

ESR-2583 ICC-ES<br />

Threaded rod (Cracked &<br />

uncracked concrete)<br />

Fire Resistance<br />

F120 (Threaded Rod)<br />

F240 (Rebar Connections)<br />

Seismic Loading<br />

C1: M12-M30 & rebar Ø12-Ø32.<br />

C2: M12-M16<br />

AS/NZS 4020:2005<br />

Drinking water applications<br />

NSF/ANSI 61<br />

Portable drinking water certification<br />

Pure150-Pro contributes toward<br />

satisfying Credit 4.1-Low Emitting<br />

Materials under LEED ® .<br />

VOC CLASSIFICATION<br />

ADHESIVE ANCHORS<br />

Applications<br />

Structural steel connections, bridges, tunnels, dams & water infrastructure,<br />

seismic upgrades, starter bars, railway, roads, post installed reinforcing connections.<br />

Description Size Box Qty Carton Qty Part No.<br />

3:1 Cartridge + 2 Mixing Nozzles 385ml 2 10 PURE150PRO-385-PWR<br />

3:1 Cartridge + 2 Mixing Nozzles 585ml 2 10 PURE150PRO-585-PWR<br />

Pure Epoxy Mixing Nozzle & Extension - 1 N/A PFPN-PWR<br />

Manual Dispensing Tool (3:1) 385/585ml 1 10 CG585-PWR<br />

Manual Dispensing Tool (3:1 & 10:1) 3:1 & 10:1 1 10 CGPRO-PWR<br />

Battery Dispensing Tool (3:1) + 2 Batteries 385/585ml 1 10 CGB-585-PWR<br />

Pneumatic Dispensing Tool (3:1) 585ml 1 10 CGPN585-PWR<br />

Installation - Hammer Drilled<br />

1 2 3 4 5 6 7<br />

8 9<br />

2X<br />

2X<br />

2X<br />

min.<br />

10 cm<br />

10hr<br />

e.g.<br />

20˚C<br />

Installation - Core Drilled<br />

1 2 3<br />

4 5 6<br />

7<br />

8<br />

9 10<br />

11 12<br />

2X<br />

2X<br />

2X<br />

2X<br />

min.<br />

10 cm<br />

10hr<br />

e.g.<br />

20˚C<br />

Connection Load Condition Hole Condition Base Material<br />

Threaded Rod<br />

Internal<br />

Threaded<br />

Sleeve<br />

Reinforcing<br />

Bar<br />

Overhead<br />

Load<br />

Static Load<br />

Quasi-Static<br />

Load<br />

Seismic*<br />

Moderate<br />

Wind<br />

High Wind<br />

Dry Hole/Wet<br />

Concrete<br />

Flooded<br />

Hole<br />

Core<br />

Drilled<br />

Concrete<br />

Cracked<br />

Concrete<br />

Sand / Lime<br />

Stone<br />

Solid Brick<br />

Stone<br />

« ▲ ▲<br />

Hollow Brick<br />

Recommended Recommended With Care Site Tests Should Be Implemented *Applies to hammer drilled holes only<br />

Detailed performance data is available for all <strong>Powers</strong> products<br />

www.powers.com.au<br />

81