Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

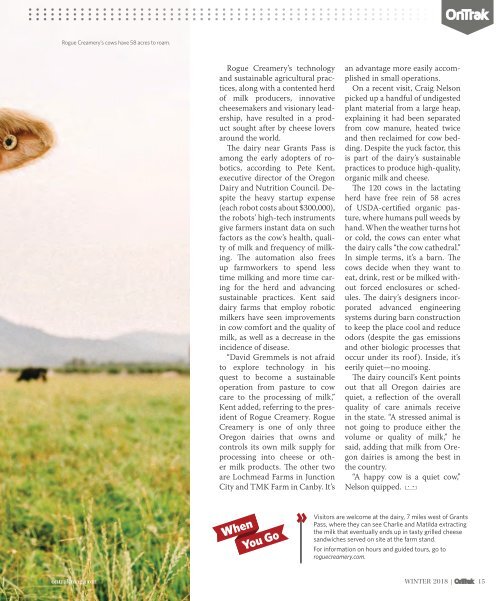

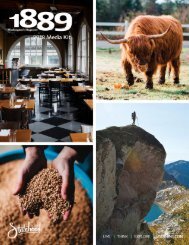

Rogue Creamery’s cows have 58 acres to roam.<br />

Rogue Creamery’s technology<br />

and sustainable agricultural practices,<br />

along with a contented herd<br />

of milk producers, innovative<br />

cheesemakers and visionary leadership,<br />

have resulted in a product<br />

sought after by cheese lovers<br />

around the world.<br />

The dairy near Grants Pass is<br />

among the early adopters of robotics,<br />

according to Pete Kent,<br />

executive director of the Oregon<br />

Dairy and Nutrition Council. Despite<br />

the heavy startup expense<br />

(each robot costs about $300,000),<br />

the robots’ high-tech instruments<br />

give farmers instant data on such<br />

factors as the cow’s health, quality<br />

of milk and frequency of milking.<br />

The automation also frees<br />

up farmworkers to spend less<br />

time milking and more time caring<br />

for the herd and advancing<br />

sustainable practices. Kent said<br />

dairy farms that employ robotic<br />

milkers have seen improvements<br />

in cow comfort and the quality of<br />

milk, as well as a decrease in the<br />

incidence of disease.<br />

“David Gremmels is not afraid<br />

to explore technology in his<br />

quest to become a sustainable<br />

operation from pasture to cow<br />

care to the processing of milk,”<br />

Kent added, referring to the president<br />

of Rogue Creamery. Rogue<br />

Creamery is one of only three<br />

Oregon dairies that owns and<br />

controls its own milk supply for<br />

processing into cheese or other<br />

milk products. The other two<br />

are Lochmead Farms in Junction<br />

City and TMK Farm in Canby. It’s<br />

an advantage more easily accomplished<br />

in small operations.<br />

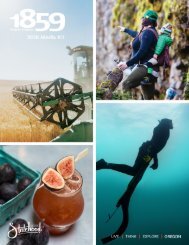

On a recent visit, Craig Nelson<br />

picked up a handful of undigested<br />

plant material from a large heap,<br />

explaining it had been separated<br />

from cow manure, heated twice<br />

and then reclaimed for cow bedding.<br />

Despite the yuck factor, this<br />

is part of the dairy’s sustainable<br />

practices to produce high-quality,<br />

organic milk and cheese.<br />

The 120 cows in the lactating<br />

herd have free rein of 58 acres<br />

of USDA-certified organic pasture,<br />

where humans pull weeds by<br />

hand. When the weather turns hot<br />

or cold, the cows can enter what<br />

the dairy calls “the cow cathedral.”<br />

In simple terms, it’s a barn. The<br />

cows decide when they want to<br />

eat, drink, rest or be milked without<br />

forced enclosures or schedules.<br />

The dairy’s designers incorporated<br />

advanced engineering<br />

systems during barn construction<br />

to keep the place cool and reduce<br />

odors (despite the gas emissions<br />

and other biologic processes that<br />

occur under its roof). Inside, it’s<br />

eerily quiet—no mooing.<br />

The dairy council’s Kent points<br />

out that all Oregon dairies are<br />

quiet, a reflection of the overall<br />

quality of care animals receive<br />

in the state. “A stressed animal is<br />

not going to produce either the<br />

volume or quality of milk,” he<br />

said, adding that milk from Oregon<br />

dairies is among the best in<br />

the country.<br />

“A happy cow is a quiet cow,”<br />

Nelson quipped.<br />

When<br />

You Go<br />

Visitors are welcome at the dairy, 7 miles west of Grants<br />

Pass, where they can see Charlie and Matilda extracting<br />

the milk that eventually ends up in tasty grilled cheese<br />

sandwiches served on site at the farm stand.<br />

For information on hours and guided tours, go to<br />

roguecreamery.com.<br />

ontrakmag.com WINTER <strong>2018</strong> | 15