Powertrain | Diesel International 2022-09

EMISSIONS CUMMINS: How to reduce consumption POWER GENERATION ROLLS-ROYCE POWER SYSTEMS: Symposium, where to experience the future EXHIBITIONS VENICE BOAT SHOW: Electric, hydrogen, diesel, LPG INTERVIEWS FPT INDUSTRIAL: Growing fast in the US and China ENGINES MAN ENGINES: Dual fuel hydrogen-engines (and V12X 2200hp) OFF-SHORE: OXE and Cox “run” diesel SCANIA: An orange mermaid at the Genoa Boat Show WÄRTSILÄ: Sustainable Technology Hub VOLVO PENTA: IMO Tier III D13 for work boats BOATS FISH-EYE: Yanmar to power Lyman-Morse Hood 35LM GERRISBOATS: A disruptive hull for electric tenders ALTERNATIVE FUELS CHEVRON: Global Centre for Maritime Decarbonisation THINK PINK UNIVERSITY OF COVENTRY: Lorena Moreira is a brilliant young engineer COLUMNS Editorial; Newsroom; Automotive; Techno

EMISSIONS

CUMMINS: How to reduce consumption

POWER GENERATION

ROLLS-ROYCE POWER SYSTEMS: Symposium, where to experience the future

EXHIBITIONS

VENICE BOAT SHOW: Electric, hydrogen, diesel, LPG

INTERVIEWS

FPT INDUSTRIAL: Growing fast in the US and China

ENGINES

MAN ENGINES: Dual fuel hydrogen-engines (and V12X 2200hp)

OFF-SHORE: OXE and Cox “run” diesel

SCANIA: An orange mermaid at the Genoa Boat Show

WÄRTSILÄ: Sustainable Technology Hub

VOLVO PENTA: IMO Tier III D13 for work boats

BOATS

FISH-EYE: Yanmar to power Lyman-Morse Hood 35LM

GERRISBOATS: A disruptive hull for electric tenders

ALTERNATIVE FUELS

CHEVRON: Global Centre for Maritime Decarbonisation

THINK PINK

UNIVERSITY OF COVENTRY: Lorena Moreira is a brilliant young engineer

COLUMNS

Editorial; Newsroom; Automotive; Techno

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

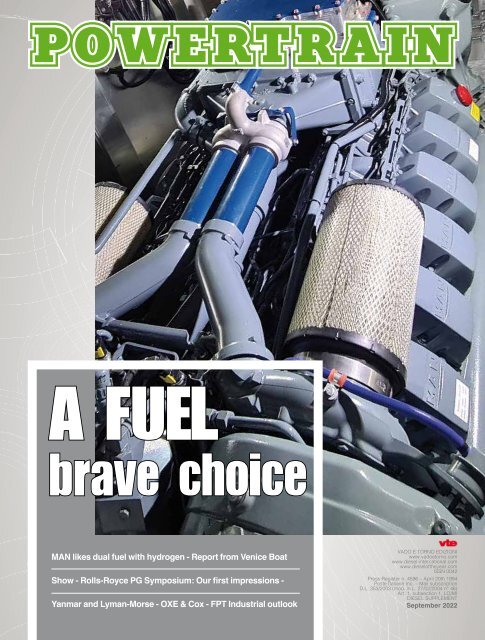

POWERTRAIN<br />

A FUEL<br />

brave choice<br />

MAN likes dual fuel with hydrogen - Report from Venice Boat<br />

Show - Rolls-Royce PG Symposium: Our first impressions -<br />

Yanmar and Lyman-Morse - OXE & Cox - FPT Industrial outlook<br />

VADO E TORNO EDIZIONI<br />

www.vadoetorno.com<br />

www.diesel-international.com<br />

www.dieseloftheyear.com<br />

ISSN 0042<br />

Press Register n. 4596 – April 20th 1994<br />

Poste Italiane Inc. – Mail subscription<br />

D.L. 353/2003 (mod. in L. 27/02/2004 n° 46)<br />

Art. 1, subsection 1, LO/MI<br />

DIESEL SUPPLEMENT<br />

September <strong>2022</strong>

HISTORY<br />

+<br />

S E R V I C E<br />

+<br />

S U P P O R T<br />

+<br />

TECHNOLOGY<br />

+<br />

D I S T R I B U T O R S<br />

POWERTRAIN diesel-international.com<br />

SEPTEMBER <strong>2022</strong><br />

GENERIC<br />

ICE<br />

H2 HYDROGEN<br />

kWe ELECTRIC<br />

GAS<br />

EMISSIONS<br />

10. CUMMINS<br />

How to reduce consumption<br />

POWER GENERATION<br />

12. ROLLS-ROYCE POWER SYSTEMS<br />

Symposium, where to experience the future<br />

EXHIBITIONS<br />

16. VENICE BOAT SHOW<br />

Electric, hydrogen, diesel, LPG<br />

INTERVIEWS<br />

20. FPT INDUSTRIAL<br />

Growing fast in the US and China<br />

CONTENTS<br />

12<br />

FIND DIESEL INTERNATIONAL ON:<br />

ENGINES<br />

22. MAN ENGINES<br />

Dual fuel hydrogen-engines (and V12X 2200hp)<br />

26. OFF-SHORE<br />

OXE and Cox “run” diesel<br />

28 SCANIA<br />

An orange mermaid at the Genoa Boat Show<br />

30. WÄRTSILÄ<br />

Sustainable Technology Hub<br />

32. VOLVO PENTA<br />

IMO Tier III D13 for work boats<br />

BOATS<br />

34. FISH-EYE<br />

Yanmar to power Lyman-Morse Hood 35LM<br />

CONNECTION.<br />

IT’S WHERE THE REAL POWER LIVES.<br />

22<br />

34<br />

38. GERRISBOATS<br />

A disruptive hull for electric tenders<br />

ALTERNATIVE FUELS<br />

40. CHEVRON<br />

Global Centre for Maritime Decarbonisation<br />

THINK PINK<br />

48. UNIVERSITY OF COVENTRY<br />

Lorena Moreira is a brilliant young engineer<br />

There’s an unbreakable bond between John Deere products and<br />

the people who choose them. It gives you the power to take your<br />

equipment where it needs to go, with premium John Deere quality<br />

standing behind you. And the power to work confidently knowing a<br />

global network of more than 9,000 John Deere dealers are ready to<br />

offer service and support whenever you need it. That’s the unique<br />

connection you get with John Deere power.<br />

JohnDeere.com/Connection<br />

COLUMNS<br />

4. Editorial 6. Newsroom 8. Automotive 42. Techno<br />

According to IRENA<br />

“Hydrogen will cover 12 percent of global energy<br />

demand and will cut 10 percent of CO 2<br />

emissions<br />

by 2050”<br />

3

EDITORIAL<br />

by Fabio Butturi<br />

HYDROGEN SEEN BY IRENA<br />

Hydrogen, object of desire, for some a mirage,<br />

for others an obsession. In this issue we report<br />

on Rolls-Royce PG applications and MAN<br />

Engines’ dual fuel system for workboats.<br />

Here are some passages from the report by<br />

IRENA, <strong>International</strong> Renewable Energy Agency.<br />

According to IRENA’s World Energy Transitions Outlook<br />

“hydrogen will cover 12 percent of global energy<br />

demand and will be cutting 10 percent of CO 2<br />

emissions<br />

by 2050. Yet, hydrogen can only be a viable climate<br />

solution if the power needed to produce it comes in<br />

addition to the electrification of the energy system,<br />

placing an even greater uptake of renewable power at<br />

the heart of the transition. If costs come down, green<br />

hydrogen below USD 1 per kilogram (kg) would be<br />

available to meet ten times the world’s energy demand<br />

in 2050. The new reports see half of the hydrogen in<br />

2050 being traded through largely existing, repurposed<br />

gas pipelines drastically reducing the costs of transport.<br />

With costs of around USD 0.10/kg per 1,000 kilometres<br />

(km) in 2050, it would be the most cost-effective option<br />

for less than 3000 km distances. By contrast, transportation<br />

through new pipelines would cost twice as much. This is<br />

still less than shipping it in the form of green ammonia<br />

4<br />

over 3,000-5,000 km, the other half of global hydrogen<br />

trade. Ammonia shipping will become the dominant<br />

form of intercontinental hydrogen trade, according to<br />

the analysis. This future pipeline-enabled trade would<br />

be concentrated in two regional markets namely Europe<br />

with the vast majority of 85 percent of the hydrogen<br />

trade and Latin America with 15 percent. Europe’s main<br />

trading partners would be North Africa and the Middle<br />

East while Australia could mainly supply Asia.<br />

New trade markets would lead to different roles for<br />

energy players. Some of the largest potential exporters<br />

of hydrogen by pipeline in 2050 are Chile, North Africa<br />

and Spain, representing almost three-quarters of the<br />

pipeline trade market. Major consumers like China<br />

and USA are able to produce most of their hydrogen<br />

domestically. Africa, Australia and North America,<br />

account for three-quarters of the global exports. On the<br />

importing side, Japan, South Korea and the EU are<br />

expected to satisfy a large share of their hydrogen<br />

demand through imports. As hydrogen becomes an<br />

increasingly internationally traded commodity, the<br />

hydrogen sector will attract growing sums of international<br />

investment. Satisfying the global hydrogen demand<br />

requires an investment of almost USD 4 trillion by 2050.”<br />

INTERNATIONAL AGRICULTURAL<br />

AND GARDENING MACHINERY<br />

EXHIBITION<br />

Contact: 00159 Roma - Italy - Via Venafro, 5 - Tel. (+39) 06.432.981 - eima@federunacoma.it<br />

THE BROADEST CHOICE<br />

OF PARTS, SPARES<br />

AND ACCESSORIES<br />

FOR AGRICULTURAL<br />

MACHINERY<br />

The strength of the Bologna<br />

event is the specialized<br />

exhibition of components for<br />

agricultural and gardening<br />

vehicles and equipment,<br />

an exhibition that for years<br />

has established itself as the<br />

most important in the world<br />

in this sector.<br />

COMPONENTS SHOW<br />

GLOBAL EXPERIENCE<br />

BOLOGNA 9 -13 NOVEMBER <strong>2022</strong><br />

Organized by<br />

In collaboration with<br />

www.eima.it

NEWSROOM<br />

#CUMMINS #DUPLOMATIC #DAIKIN<br />

CUMMINS CEO<br />

DAIKIN TO ACQUIRE DUPLOMATIC MOTION SOLUTIONS<br />

JENNIFER<br />

RUMSEY<br />

On June 30 th , <strong>2022</strong> Daikin Industries has<br />

obtained all shares of Duplomatic Motion<br />

Solutions and it has completed its acquisition.<br />

Through this transaction, Daikin will have an<br />

extensive product lineup, robust engineering<br />

capabilities for hydraulic systems and a strong<br />

business foundation in Europe. Together with<br />

Daikin hybrid system technologies, the aim<br />

is to offer to the market high tech solutions<br />

to reduce environmental load. Backed by 70<br />

years of technology innovation and industry<br />

expertise, Duplomatic is known for its advanced<br />

engineering and a world-class operation with its<br />

multiple brands and worldwide manufacturing<br />

facilities. Following the transaction Roberto<br />

Maddalon, in Duplomatic since 1996, will<br />

continue to lead as CEO the business going<br />

forward. He said: “The integration with Daikin<br />

will enable to accelerate the development and<br />

the deployment of new technologies and this<br />

will enhance our product portfolio and offer<br />

of sustainable solutions to our customers.”<br />

Yuya Kimura, newly assigned Vice President<br />

of Duplomatic from Daikin Industries, said:<br />

“We have closely tracked Duplomatic’s<br />

outstanding growth over the past several years.<br />

Daikin fully admires Duplomatic’s committed<br />

and passionate team members, and strongly<br />

believes that this integration should further<br />

accelerate the growth by delivering new values<br />

and experiences to both our existing business<br />

partners and potential customers worldwide.”<br />

“I am grateful to Tom<br />

for his support over<br />

the years. My technical<br />

background, business<br />

experience and focus<br />

on people, purpose, and<br />

impact have prepared<br />

me for this moment.”<br />

Jennifer Rumsey is going to<br />

take the role of President and<br />

CEO of Cummins starting 1 st<br />

August <strong>2022</strong>. Currently she<br />

hold the position of President and<br />

Chief Operating Officer (COO).<br />

She’ll replace Tom Linebarger, who<br />

will continue to serve as Chairman<br />

of the Board and Executive Chairman.<br />

Jennifer Rumsey will be the<br />

seventh CEO and first woman to lead<br />

the company since it was founded<br />

in 1919. Linebarger, as mentioned<br />

above, will continue to serve as<br />

Chairman of the Board of Directors<br />

and in an Executive Chairman role,<br />

working directly with Rumsey on<br />

specific initiatives that position the<br />

6<br />

company for continued success, including<br />

completing the pending acquisition<br />

of Meritor.<br />

Since taking on the role of COO in<br />

March 2021, Jennifer Rumsey has<br />

overseen Cummins’ global operations.<br />

In February <strong>2022</strong>, she was<br />

elected to the Cummins Board of<br />

Directors, and she will maintain her<br />

seat on the board.<br />

The new Cummins’ CEO Jennifer<br />

Rumsey began her Cummins career<br />

working in Research and Technology,<br />

primarily focused on advancing<br />

technology to reduce criteria pollutants<br />

from diesel engines. Since<br />

then, she has held numerous positions<br />

of increasing responsibility<br />

and impact, including bringing new<br />

platforms and technologies to the<br />

market, driving improvements in<br />

product quality, and developing the<br />

capability of global teams, the group<br />

says. She has also been deeply engaged<br />

with some of the company’s<br />

most important original equipment<br />

manufacturer (OEM) partners. The<br />

leadership roles Rumsey has held<br />

include President of Components,<br />

where she oversaw a global portfo-<br />

lio of business units that delivered<br />

profitable growth while ensuring<br />

power solutions met performance<br />

and emissions goals, and Chief<br />

Technical Officer, where she led<br />

strategic investments in key technologies<br />

and applications to transition<br />

to lower carbon emissions products,<br />

laying the foundation years ago for<br />

the company’s New Power Business<br />

and Destination Zero strategy.<br />

Prior to Cummins, Rumsey worked<br />

for a fuel cell technology company.<br />

Jennifer Rumsey is a member of<br />

the Society of Women Engineers,<br />

Society of Automotive Engineers,<br />

the Purdue Engineering Advisory<br />

Council and Women in Trucking Association.<br />

She holds a Bachelor of<br />

Science in Mechanical Engineering<br />

from Purdue University and a Master<br />

of Science in Mechanical Engineering<br />

from Massachusetts Institute<br />

of Technology. Throughout her<br />

career, she has been an advocate for<br />

diversity, equity and inclusion and<br />

women in STEM fields. She lives in<br />

Columbus with her husband and has<br />

two college age daughters who are<br />

both pursuing engineering degrees.<br />

Motorcycle cylinders<br />

honing machine<br />

from Ø35 to Ø120 mm<br />

HONITECH<br />

Two or three spindles honing<br />

machine far roughing, finishing<br />

and plateau<br />

Honitech S.r.l.<br />

Tel: +39 02 6152662<br />

Video links on honitech.net

AUTOMOTIVE<br />

#INTERNALCOMBUSTIONENGINES #DECARBONIZATION #EUROPEANUNION<br />

“FIT FOR 55” BY EU<br />

FIT<br />

0R<br />

UNFIT?<br />

“Fit for 55” refers to the EU’s target of reducing net<br />

greenhouse gas emissions by at least 55% by 2030 .<br />

On the 8 th of June, the plenary<br />

session of the European Parliament<br />

in Strasbourg approved<br />

the “Fit for 55” plan. Besieged<br />

by cross-party alliances involving even<br />

the sovereignists of the ID group where<br />

Marine Le Pen and the German AFD sit,<br />

the “Fit for 55” initiative was rejected on<br />

practically every point: from the carbon<br />

tax to green ETS credits. While the entire<br />

“Fit for 55” was returned to the European<br />

Parliament’s Environment Commission,<br />

a jolt of unanimity amongst the Members<br />

of the European Parliament led to<br />

the approval of a ban, entering into force<br />

in 2035, on the sale of cars and light vehicles<br />

(up to 3.5 tonnes of total mass)<br />

whose engines emit greenhouse gases<br />

(CO 2<br />

). The only ones to be pardoned are<br />

those manufacturers of series of vehicles<br />

that make less than a thousand units/year.<br />

A defeat first and foremost for ACEA,<br />

the Association of European Automobile<br />

Manufacturers, which has survived<br />

months of capillary lobbying to mitigate<br />

the impact of “Fit for 55” on the European<br />

automotive world. It is no coincidence<br />

that, within a short time, Stellantis’ CEO<br />

Carlos Tavares announced the exit of the<br />

Franco-Italian-American group from the<br />

association led in recent times first by<br />

Sergio Marchionne and then by Philippe<br />

Varin, CEO of PSA Peugeot Citroën.<br />

In a very British style, far from Mar-<br />

European Parliament<br />

approved “Fit for 55”<br />

plan. After 2035, no<br />

ICE will be produced<br />

anymore<br />

chionne’s invectives, Tavares clarified:<br />

“The environmental challenges ahead of<br />

us, together with a rapidly changing economic<br />

environment, require an efficient,<br />

global and inclusive all-round approach<br />

involving all those who wish to contribute<br />

to the construction of a sustainable<br />

mobility. Access to clean, safe and affordable<br />

mobility for citizens around the<br />

world is at stake.” The fact that Tavares,<br />

together with another “big” like Akio<br />

Toyoda, has little faith in the feasibility<br />

of an “all-electric” future is nothing new.<br />

And someone, again on a global level,<br />

points out how the harmony between<br />

the first (Toyota) and fifth (Stellantis)<br />

world car manufacturers with regards to<br />

the future of sustainable mobility puts<br />

the Franco-German axis created by the<br />

Renault-Nissan and Volkswagen groups<br />

(number three and two respectively) in a<br />

difficult position, since they count on the<br />

economic incentives promised by the<br />

governments of Paris and Berlin; neutral<br />

on this issue is Hyundai-Kia (number<br />

four), drawing its strength from the experience<br />

accumulated in China. Tavares’<br />

“free hands” choice has a motivation<br />

that highlights his skills as a pragmatic<br />

manager. If the Greens are celebrating<br />

the “Stop in 2035”, the chaos staged<br />

in Strasbourg on the 8 th of June and –<br />

above all – the implosion on “Fit for 55”<br />

of the majority, that has so far supported<br />

the Commission in the European Parliament,<br />

represents a golden opportunity<br />

for Stellantis’ CEO in view of the second<br />

half of the game, the opening of which<br />

is scheduled for the 28th of June, with<br />

the EU Council of Environment (we<br />

are writing a few days before this date,<br />

editor’s note). The hypothesis is that the<br />

meshes of the EU project will widen,<br />

lowering the expected reduction in CO 2<br />

emissions from 100 to 90 percent, an objective<br />

that is not impossible for internal<br />

combustion engines already in the Euro7<br />

version. However, in the EU buildings,<br />

many politicians and officials seem to<br />

ignore two key facts. The first one is that<br />

only 12 percent of CO 2<br />

emissions in the<br />

whole EU comes from cars. No one, in<br />

fact, has contradicted the well-known<br />

study according to which, on an annual<br />

basis, the cruise ships anchored with<br />

their generators running at the harbour<br />

of Barcelona pollute as much as the entire<br />

European car fleet. In terms of global<br />

impact on the planet, then, the 2021<br />

registration figures show that the 16.8<br />

million new vehicles in the European<br />

area represent only 20 percent of the<br />

world figure, which sees Asia in the lead<br />

with 42.6 million vehicles, where China<br />

stands out with its 26.2 million cars.<br />

Eliminating EU emissions, therefore,<br />

risks to be more of an exercise in style<br />

rather than an advantage for the environment.<br />

Without forgetting the problem of<br />

raw materials, as Andrea Boitani, Professor<br />

in Transport Economics at the Catholic<br />

University of Milan, pointed out:<br />

“The Chinese have been quicker, and as<br />

for rare earth elements, especially lithium<br />

(essential for batteries), they have<br />

already signed exclusive and advantageous<br />

agreements with the governments<br />

of their producer countries, mostly in Africa.”<br />

If it is true that “failure is simply<br />

the opportunity to begin again, but this<br />

time more intelligently”, as Henry Ford<br />

loved repeating, perhaps the Strasbourg<br />

disaster could be a new beginning for the<br />

European automotive industry.<br />

8<br />

9

EMISSIONS<br />

#CUMMINS #PERFOMANCESERIES #CONSUMPTION #STAGEV<br />

CUMMINS<br />

SEVEN<br />

GOOD<br />

TIPS<br />

FROM UK TO SOUTH KOREA<br />

Cummins has announced that its Darlington Engine Plant’s 1.5<br />

millionth Mid-Range engine has made it across the globe to South<br />

Korea and been installed into a Hyundai excavator. In January,<br />

Cummins revealed that it had manufactured its 1.5 millionth Mid-<br />

Range engine, a B5.9, at its Darlington factory in the north-east<br />

of England. Since then, the team at Darlington has been tracking<br />

the progress of its now “famous” engine and have estimated that<br />

it travelled over 5,400 miles from Darlington to machine plant<br />

at Ulsan City, South Korea. The 5.9-litre engine has been fitted<br />

into a 22-ton HX220S Hyundai excavator, providing the power for<br />

thousands of hours of heavy workload. This is not the end of the<br />

1.5 millionth engine’s journey as the excavator is destined for a<br />

customer in Guatemala at the end of May. Cummins’ Darlington<br />

factory produced 66,000 engines in 2021, and employs around<br />

1,500 people working in engine assembly, exhaust aftertreatment<br />

manufacture, technical operations, and business support functions.<br />

It manufactures engines spanning a range of 3.8 to 9-litre<br />

displacement (75 to 430 hp), powering a wide range truck, bus,<br />

construction, agriculture, material handling, marine and power<br />

generation applications around the world.<br />

Steve Nendick, Cummins: “Despite what many in the industry<br />

have heard, stop-start systems don’t compromise engine life<br />

as they are tailored specifically to the duty cycles of the machine<br />

and operation, and have optimised components.”<br />

lored specifically to the duty cycles of<br />

the machine and operation, and have<br />

optimised components. The system<br />

also automatically limits the number<br />

of stop-starts per hour, unlike a car.<br />

So, if the machines have timed idle<br />

shut-off or stop-start capability, this<br />

should be switched on. Cummins offers<br />

stop-start on its Performance Series<br />

engines and in real-world trials<br />

we’ve seen it deliver fuel savings of<br />

10% compared to standard engines.<br />

Can the work be done in Eco mode?<br />

Although many operators dismiss Eco<br />

mode (or downright hate it) the mode<br />

will automatically reduce engine<br />

speed and save fuel. Don’t ignore it.<br />

Switch it on. Many newer machines<br />

come with monitoring facilities as<br />

standard. By analysing their data, operators<br />

can find operational efficiention.<br />

Idling wastes fuel, regardless<br />

of how efficient the engine is. Yet despite<br />

this, it’s often a common practice<br />

(we’ve all seen operators eating their<br />

lunch in an idling machine). By simply<br />

killing the engine when it’s not in<br />

use, operators can save fuel, as well<br />

as reduce emissions and prolong the<br />

life of their machine by cutting unnecessary<br />

wear on components. Despite<br />

what many in the industry have<br />

heard, stop-start systems don’t compromise<br />

engine life as they are tai-<br />

Cummins tells us<br />

the seven top tips<br />

for reducing fuel<br />

consumption<br />

Emission nearly rhymes with<br />

consumption. A need, that of<br />

reducing the environmental impact<br />

of the diesel engine, which<br />

goes hand in hand with the dramatic<br />

increase in the cost of oil. Brent<br />

is stable at USD 113, and refuelling<br />

costs at gas stations are now out of<br />

control, stably above EUR 2 per litre<br />

in several European countries (Monday<br />

27 June). The recipe has the usual<br />

ingredients (combustion chamber<br />

pressure, injection, efficiency, ATS<br />

etc.), what changes is the skill of the<br />

cook. In this case it is Steve Nendick,<br />

Marketing Communications Director<br />

for Global Off-Highway at Cummins,<br />

who tells us about the alchemy of Columbus.<br />

“We’re delighted to share our seven<br />

top tips for reducing fuel consump-<br />

cies by understanding how equipment<br />

is being used, such as excessive idling<br />

or aggressive use of the throttle”.<br />

Predictive maintenance is another lever<br />

to keep the engine in top shape.<br />

It not only benefits TCO as an overall<br />

figure, avoiding downtime, but also<br />

the smoothness of clutches and the<br />

prevention of the effects of oil residues<br />

and clogged nozzles, to give two<br />

examples.<br />

“Monitoring also helps to detect potential<br />

service problems in advance<br />

and reduce repair costs and downtime.<br />

Cummins Guidanz supports this<br />

capability on electronically connected<br />

engines, for example. Understanding<br />

and following recommended maintenance<br />

schedules is critical to ensure<br />

that equipment gives optimum performance.<br />

Poorly maintained machines<br />

will use more fuel for the same amount<br />

of work as a well maintained one.<br />

Preventive maintenance also saves<br />

major repairs in the long term, maximising<br />

the productivity and life of the<br />

engine. Continuing with the theme of<br />

things that are often ignored… Follow<br />

the OEM’s recommendations to ensure<br />

that correct fluids (such engine,<br />

hydraulic and axle oil) are used and<br />

kept at the required levels. Additional<br />

checks on the cleanliness of radiators,<br />

radiator screens and air filters, as well<br />

as having the correct tyre air for the<br />

intended job, are also important to deliver<br />

optimal fuel efficiency. Consider<br />

updating your plant and equipment. As<br />

always there is a balance to be struck<br />

between capital and operational expenditure,<br />

but the high cost of fuel may<br />

just tip the scales towards the former<br />

for some operators with older, less efficient<br />

equipment. By purchasing new,<br />

or newer, machines, operators can<br />

reap the benefit of diesel engine technologies<br />

that have been pushed higher<br />

up their evolutionary ladder, getting<br />

increasingly fuel efficient, reliable<br />

and cleaner. For example, Cummins’<br />

latest Performance Series engines use<br />

less fuel than their previous generation,<br />

providing a substantial fuel cost<br />

saving over the life of the engine and<br />

the machine. Finally, it’s worth investing<br />

time, money, and effort in training<br />

staff for the equipment they operate.<br />

Poorly trained staff will be more likely<br />

to mishandle the machine, increasing<br />

fuel consumption. As monitoring<br />

capability develops, the data gathered<br />

will be able to help improve operator<br />

training”.<br />

10<br />

11

POWER GENERATION<br />

#ROLLSROYCEPOWERSYSTEMS #FRIEDRICHSHAFEN #ELECTROLYZERS<br />

ROLLS-ROYCE PG SYMPOSIUM<br />

JOURNEY<br />

TO NET<br />

ZERO<br />

BERGHOF SOLAR PARK IN TENGEN<br />

The new Berghof solar park in Tengen, southern<br />

Germany, opened on Friday 3 June <strong>2022</strong>. The plant has<br />

an output of 3.7 megawatts and will generate around<br />

four million kilowatt hours of CO 2<br />

-free electricity per<br />

year for Rolls-Royce Power Systems, saving 1,300<br />

tons of CO 2<br />

a year compared with electricity available<br />

through the German grid network. The new solar park<br />

takes Rolls-Royce another step closer to its goal of<br />

achieving net zero greenhouse gas emissions from its<br />

operations and facilities as Power Systems has signed<br />

a power purchase agreement with the operators for<br />

an initial period of ten years. “With our Net Zero at<br />

Power Systems program, we are pursuing strict climate<br />

protection targets,” explained Otto Preiss, Rolls-Royce<br />

Power Systems Chief Technology Officer and COO.<br />

“With ambitious interim targets for 2030, we aim to<br />

be completely climate neutral by 2050 across all global<br />

sites and areas from production to supply chains to our<br />

product portfolio, i.e. in all three recognized categories<br />

Scope 1, 2 and 3.”<br />

The word “symposium” comes<br />

from the ancient Greek (fifth<br />

century BC) and means “conference”.<br />

The first three letters<br />

translate as “with”. So, what did<br />

the PG Symposium at Rolls-Royce<br />

Power Systems get us “with”? At the<br />

Friedrichshafen Trade Fairs we understood<br />

some mtu key points. We<br />

summarize here: “Our intention is<br />

not to sell components, but become<br />

a solution provider for power systems”.<br />

And, “actually are not the<br />

companies who decide what the future<br />

looks, we’re offering options. We<br />

have to handle all the technologies.<br />

Everything is possible...” Finally,<br />

“we’re not stopping any investment<br />

on diesel technology, because we are<br />

also convinced that this technology<br />

is part of the future. According to<br />

our forecast for 2030, the 2/3 of our<br />

revenues will be generated by our<br />

power systems based on diesel engine<br />

technology: 1/3 will still based<br />

on fossil fuels, 1/3 on sustainable fuels<br />

and 1/3 with new technologies.”<br />

Rolls-Royce Power Systems is ready<br />

Rolls-Royce Power<br />

Systems’ PG<br />

Symposium <strong>2022</strong> was<br />

held in Friedrichshafen<br />

under the banner of<br />

technological flexibility<br />

and being agnostic to<br />

differentiate the ways<br />

towards Net Zero<br />

to meet market demands, which will<br />

be driven by policy makers and technology<br />

upgrades still in the incubation<br />

phase. This is demonstrated by<br />

the recent acquisition of the 54%<br />

majority stake in electrolysis stack<br />

specialist Hoeller Electrolyzer. Otto<br />

Preiss, COO and Chief Technology<br />

Officer, said: “By developing our<br />

own mtu electrolyzers and by taking<br />

a majority stake in Hoeller Electrolyzers,<br />

we are methodically growing<br />

our hydrogen portfolio and securing<br />

access to this fascinating technology,<br />

which is not a pipe dream but has<br />

great market potential.” In hydrogen<br />

electrolysis, water is subjected to DC<br />

electrical current, producing hydrogen<br />

at the negative pole and oxygen<br />

at the positive pole. In this way, it is<br />

possible to produce carbon neutral<br />

hydrogen by using electricity from<br />

renewable sources such as solar or<br />

wind. The electrochemical reaction<br />

takes place in a cell between plateshaped<br />

electrodes separated by membranes.<br />

Hundreds of cells located one<br />

above the other and pressed together<br />

form a “stack”, the heart of an electrolyzer.<br />

Development work on the<br />

first mtu electrolyzer using a stack<br />

from Hoeller Electrolyzer is already<br />

underway. In 2023, it will go into<br />

operation at the Validation Center in<br />

Friedrichshafen to demonstrate how<br />

an electrolyzer fits into the overall<br />

architecture of a microgrid. An initial<br />

customer project is already planned<br />

for 2024.<br />

We talked about mtu fuel cell systems<br />

with Mario Scala, Validation<br />

Engineer mtu fuel cell. “Our goal,”<br />

Scala said, “is the integration of<br />

modules into the container, to supply<br />

energy to the data centres from the<br />

integration of individual modules.<br />

What we are displaying here at the<br />

microgrid centre are four modules<br />

supplied by Cellcentric capable of<br />

delivering 65 kilowatts each. Our<br />

intention is to add more, more powerful<br />

modules to deliver even 1 MW<br />

prime power containers. The module<br />

was developed for the automotive<br />

industry and is used here for testing<br />

purposes. On the test bench we have<br />

a development that comes from industry,<br />

and produces 110 kW each.<br />

By 2023, the development will take<br />

them to 150 kW. Our demonstration<br />

project involves the delivery of three<br />

containers to the port of Duisburg, a<br />

collaboration that includes a testing<br />

phase at the customer and delivery of<br />

the first ones by the summer of 2023,<br />

to be followed by a joint development<br />

stage.” And now we report on<br />

some exchanges we had with Tobias<br />

Ostermaier, President of Stationary<br />

Power Solutions. “Take a look at<br />

our product lineup from three years<br />

ago,” he started “when gas and diesel<br />

engines dominated. Today, we<br />

have electrolyzers, a larger portfolio<br />

of energy solutions, dynamic gas<br />

solutions, and an investment in automation.<br />

In short, we have everything<br />

we need to establish ourselves as a<br />

solution provider.” Because this is<br />

the goal, which we have anticipated:<br />

to become a supplier of complete,<br />

integrated systems, capable of supporting<br />

technological development<br />

in an “agnostic”way, as Ostermaier<br />

12<br />

13

POWER GENERATION<br />

#ROLLSROYCEPOWERSYSTEMS #FUELCELL #HYDROGEN #DATACENTERS<br />

DATA CENTERS TOWARDS NET ZERO<br />

According to the results of a study by the Borderstep Institute,<br />

the energy consumption of data centers in the EU alone was 76.8<br />

TWh in 2018. The estimates show a 28% increase to 98.52 TWh<br />

by 2030. On the way to climate neutrality, this electricity must<br />

also be generated green. What role do diesel generators play<br />

in this? And the fuel cell? Energy expert Tobias Bertler (Senior<br />

Manager Direct Sales & Business Development APAC) and Ryan<br />

Murphy (Sales Lead for Data Center Solutions in North America),<br />

from Rolls-Royce Power Systems provide an outlook.<br />

How concerned about sustainability are data center operators<br />

when it comes to back up power?<br />

Tobias Bertler: Data center operators are very interested in<br />

sustainable backup power solutions. This is partly because the<br />

entire data center market is dominated by the large technology<br />

companies, which are very much in the public eye and feel a<br />

social responsibility to reduce their carbon footprint. This has<br />

also moved data center emergency power systems into the<br />

fore. Although they have only a few operating hours, gigantic<br />

capacities with a very high available power are being built for<br />

these mission-critical data centers.<br />

himself points out. For example in<br />

a microgrid? We asked Jan Henker<br />

for more details, Senior Expert Automations<br />

& Controls Sustainable<br />

Solutions. “When it comes to the<br />

optimization of the overall system,<br />

we do have a magnetic optimization<br />

algorithm and that is basically using<br />

different forecast approaches, exactly<br />

for the GPS coordinates, for instance<br />

how much sun and how much<br />

wind will that be in. We’re going to<br />

mathematical optimization, carefully,<br />

continuously, to understand what<br />

is the best energy mix etc.”<br />

What’s happening in 2030 or in<br />

2035?<br />

Ostermaier: For that, there are two<br />

lenses. Right now, no one can truly<br />

know it. We’re thinking about the<br />

technology of today. Just think of<br />

is now investing in a smart grid, this<br />

is still significant.<br />

Why “killing” diesel engines for<br />

stand-by gensets in hospitals and<br />

data centres?<br />

We’re not killing diesel engines, and<br />

European Union overnight thought<br />

about that. Actually, what they did<br />

most recently was to acknowledge<br />

that sustainable fuels must play a<br />

crucial part in the energy transition.<br />

This sends a very critical message to<br />

the entire sector. This is a big decision<br />

because there will be an infrastructure<br />

built around sustainable<br />

fuels, and it’s a big possibility to use<br />

current technology with sustainable<br />

fuels. ICE and sustainable fuels will<br />

be a part of the solution, as well as<br />

the efforts of our industry.<br />

Hydrogen internal combustion enhow<br />

much CO 2<br />

would be saved if all<br />

of our current engines were converted<br />

to HVO. We’re talking about more<br />

than 100,000 engines in the field.<br />

What applications for hydrogen in<br />

power generation?<br />

Hydrogen will play a major role.<br />

The availability of hydrogen and the<br />

extent to which it will be accessible<br />

are the main issues. Infrastructure<br />

and accessibility... There isn’t much<br />

hydrogen accessible right now, but<br />

there might be in the next few years.<br />

Our side also offers the possibility<br />

of utilizing current gas systems.<br />

Our systems are presently capable of<br />

burning 10% hydrogen, and we will<br />

soon have the option to use 25% hydrogen.<br />

As a third alternative, we can<br />

retrofit current gas systems to run<br />

100% hydrogen. And even if a client<br />

gines vs fuel cells? Who’s the winner?<br />

In the century of fossil fuels, diesel<br />

dominated every application. I firmly<br />

believe that there won’t be another<br />

dominant technology in the future.<br />

ICEs will make more sense in some<br />

situations, whereas fuel cells will<br />

make sense in other situations. Our<br />

energy portfolio needs to be diversified<br />

in a variety of ways. We need to<br />

manage every technology.<br />

What if Rolls-Royce became the single<br />

supplier of the smart grid, including<br />

solar panels? “We already have<br />

a microgrid in place at our facility<br />

in Friedrichshafen (see box on page<br />

13) and we will install another smart<br />

grid at each of our facilities throughout<br />

the world, including our manufacturing<br />

in Aiken, in the US.”<br />

Is there still a big demand for diesel gensets from data center<br />

operators?<br />

Tobias Bertler: Definitely. Today every mission-critical data center<br />

has backup power systems built into it that typically run on diesel<br />

fuel. Rolls-Royce Power Systems delivered over the course of<br />

the years approximately a total capacity of 5 GWe emergency<br />

power units into the global data center business. This was also<br />

demonstrated in our diesel emergency power systems business.<br />

We have also further expanded our range of power supply<br />

systems for mission-critical applications with the acquisition of<br />

Kinolt as a leading company for dynamic UPS systems. <strong>Diesel</strong><br />

gensets currently offer the highest safety and most coherent<br />

technical characteristics for mission-critical energy systems.<br />

What can you say about the North American data center market?<br />

Ryan Murphy: The North American data center market continues<br />

to grow exponentially, over 35% CAGR, and is expected to exceed<br />

$90 billion USD by 2027. This growth is led by the dominance of<br />

hyperscale data center customers through both their own construction<br />

and record lease deals with colocation providers. There<br />

has been a lot of consolidation in the market as the players seem<br />

to get larger and more sophisticated. These customers are not<br />

only demanding higher quality and reliability in their products, but<br />

also greener solutions moving forward such as HVO fuel, exhaust<br />

aftertreatment, battery energy storage, and hydrogen.<br />

14<br />

15

MARINE<br />

#FPTINDUSTRIAL #BIMOTOR #VENICEBOATSHOW #LABIENNALE<br />

VENICE BOAT SHOW<br />

NEED<br />

OF<br />

THE FPT Industrial F1 engine is an integral feature<br />

of the installation at the Italian Pavilion of the Venice<br />

Biennale of Contemporary Art. The entire pavilion<br />

is given over to an artwork by artist Gian Maria<br />

Tosatti with an environmental installation, curated<br />

by Eugenio Viola, called “History of Night and<br />

Destiny of Comets”, which explores the relationship<br />

between man and nature and encourages reflection<br />

on the current state of humanity and its future<br />

prospects, explicitly referring to the United Nations<br />

2030 Agenda for Sustainable Development.<br />

Below, Carlo Moroni, Head of FPT Industrial<br />

Brand Communication, and Gian Maria Tosatti<br />

in front of the engine in the Italian Pavilion at the<br />

59 th <strong>International</strong> Art Exhibition.<br />

SILENCE<br />

Bimotor has recently acquired<br />

FPT Industrial’s dealership for<br />

Australia as well, through its<br />

subsidiary Bepower Solutions.<br />

The operational headquarters will be<br />

in Melbourne. FPT is in fact moving<br />

from a Eurocentric position to a more<br />

global vision of the marine market, although<br />

Europe still remains central. At<br />

Bimotor’s stand, Carmine Bagnoli told<br />

us about the displayed engines: “Our<br />

engines power more than a hundred<br />

steamboats in the Laguna. The Cursor<br />

9 is one of the most present on these<br />

applications. We have adopted a novel<br />

supercharger for this power size,<br />

which allows high torque values to be<br />

achieved at very low revs. It is of the<br />

conventional fixed-geometry type, but<br />

has so far been used on smaller engines.<br />

Let’s now move on to the 4-litre<br />

common rail, 125 kW at 2,800 rpm,<br />

which is interesting for commercial<br />

applications due to its compact packaging<br />

and its power and torque density.<br />

It is ideal for waste collection services.<br />

Finally, the N67, a very versatile<br />

Stage V homologated unit, without after-treatment,<br />

which meets the needs of<br />

northern European users (Benelux and<br />

Scandinavian countries). In a way, I<br />

The amazing scenario<br />

of the ancient Arsenal<br />

hosted the Venice Boat<br />

Show. We talked with<br />

FPT Industrial and<br />

Bimotor, Geminiani, AS<br />

Labruna and Autogas<br />

would call this a hybrid configuration,<br />

since it can also be used as a generator<br />

for a variable-speed electric machine,<br />

thus functioning as a range extender.”<br />

Fabrizio Polito talks about their customer<br />

service. “The services revolve<br />

around three fundamental pillars: reliability,<br />

both with original FPT spare<br />

parts and technical support; ‘protection’,<br />

with customised contractual<br />

coverage; and digital evolution. As<br />

for the uptime, our commitment starts<br />

with MyFPTApp, which establishes an<br />

initial connection with the end customer.<br />

The natural evolution of this<br />

tool is its integration with a dongle,<br />

via Bluetooth, which can be mounted<br />

on the engine’s diagnostic port and allows<br />

for additional functionalities, for<br />

example real-time performance data<br />

and display of errors in the ECU. The<br />

extended warranty packages can be<br />

combined for up to five years of engine<br />

life and can be configured according to<br />

the number of hours, years of use and<br />

perimeter of coverage.”<br />

Also displayed at Geminiani’s stand<br />

was the Kangaroo, the Giugiaro’s electric<br />

hyper-SUV. Andrea Tirone, Geminiani’s<br />

Sales Manager, explained:<br />

“Customers who get in contact with us<br />

at the exhibition often come to see us<br />

at our headquarters; seven out of ten<br />

requests concern the electric alternative.<br />

The power pack has also become<br />

electric, with Giugiaro’s contribution.<br />

We can supply everything, even the<br />

connectors, the “famous” plug&play<br />

system. A nice advantage for the ship<br />

owner: the power pack has a definite<br />

cost and does not need anything else.”<br />

Massimo Geminiani then intervenes:<br />

“We have drawn up an agreement with<br />

Giugiaro for the electric car range,<br />

from 25 to 400 kilowatts, which integrates<br />

a crucial element such as the<br />

power pack, and we have signed a contract<br />

to equip six taxis in Qatar, used<br />

by real estate agencies to show flats<br />

overlooking the Gulf.”<br />

How is the collaboration with Caterpillar<br />

proceeding?<br />

“Caterpillar is one of the few that has<br />

managed to keep its word, even in<br />

this troubled period of absolute supply<br />

shortage, by sending us what we<br />

requested on time. Caterpillar is our<br />

supplier in the range between 19 and<br />

200 kilowatts, i.e. from C.1 to C.7.<br />

Also, with their contribution we are<br />

able to implement the philosophy that<br />

inspires us in the electrification field,<br />

with a variable-speed generator that<br />

charges the battery thus providing current<br />

to the system.”<br />

With the electrification process comes<br />

a tendency to outsource expertise to<br />

specialists.<br />

“An approach that is justified by the<br />

need to have the right skills and profiles<br />

to create software, exclusively<br />

dedicated to that particular type<br />

of project. We are willing to set up a<br />

customizable power pack, a challenge<br />

that is only possible if you have the inhouse<br />

staff to design the software. The<br />

system has to enable the management<br />

of throttle, accelerator, loads, sensors<br />

and the machine itself. In this context<br />

there is more and more room for system<br />

engineers. Companies like ours<br />

know the OEMs and their needs, power<br />

absorption, load, operating modes<br />

and potential of the electrics.”<br />

16<br />

17

MARINE<br />

#GEMINIANI #ASLABRUNA #AUTOGAS<br />

Massimo Labruna is also a regular<br />

exhibitor of the Venice Arsenal, and<br />

we talked about hydrogen with him:<br />

closest to the AS Labruna’s stand was<br />

a demo. “We have come up with a concept,<br />

in every sense of the word, that<br />

is scalable to larger vessels, where the<br />

criticality comes from the power of<br />

the fuel cells, with a bar raised to 300<br />

kilowatts, which is still a respectable<br />

power. This is how we plan to solve the<br />

long-standing problem of the autonomy<br />

of full-electric boats. The vessel<br />

is equipped with two electric motors,<br />

a buffer battery pack and hydrogen<br />

fuel cells that recharge the batteries.<br />

Summarising and detailing the architecture,<br />

there are two outboard motors<br />

of 6 kilowatts each, while the battery<br />

pack delivers just 5 kilowatts. So, with<br />

an installed power of 12 kilowatts, the<br />

tute for generators in serial hybrids. In<br />

our hydrogen journey, we had started<br />

with methanol fuel cells, obtained by<br />

CO 2<br />

abatement. That project is still<br />

up and running, albeit on very small<br />

sizes. Here in Venice, we are showing<br />

another approach, since in this case<br />

we started off with a completely electric<br />

boat. Today we can boast an absolutely<br />

complete electric range, with<br />

electric outboards and inboards, electric<br />

pods, hybrid kits on both high and<br />

low-powered diesels, serial and parallel<br />

hybrids, fuel cells, hydrogen and<br />

methanol. The general principle that<br />

inspires us is the maximum reduction<br />

of the battery pack, also because if you<br />

don’t have a power source on board<br />

you have to recharge it at the dock.<br />

This problem is solved if there is a renewable<br />

source on board; without divcapacity<br />

of the battery pack is 5 kilowatt-hours.<br />

The two-kilowatt fuel cells<br />

can run for about 10 hours, thanks<br />

to the on-board hydrogen cylinders,<br />

which on the anchor model contain<br />

30 litres. Essentially, I have stored 20<br />

kilowatt-hours of energy, in addition to<br />

5 kWh obtained from buffer batteries,<br />

which gives us a significant autonomy,<br />

bypassing the most difficult limitation<br />

of all-electric power supplies. In order<br />

to increase the autonomy, it would be<br />

necessary to increase the battery packs,<br />

thus increasing weight and costs, since<br />

the boat runs at reduced speed and<br />

does consume more to achieve the<br />

same performance. There is a threshold<br />

limit that cannot be exceeded.<br />

In this system, the fuel cells function<br />

as range extenders, thus enabling a<br />

greater autonomy, acting as a substi-<br />

ing into waters, this is an issue concerning<br />

any application, even cars.<br />

In order to store energy, the battery<br />

needs a long recharge time, unlike the<br />

hydrogen cylinder or methanol tank”.<br />

Also at the AS Lavruna stand was<br />

CMD’s BlueHybrid system, equipped<br />

with a hybrid control unit, which controls<br />

both the endothermic engine and<br />

the electric motor and communicates<br />

with the GPS signal, so that it automatically<br />

converts the navigation to<br />

the electric mode.<br />

In 2021 Autogas, acquired by Ecomotive<br />

Solutions, broke the threshold of<br />

3,000 bifuel petrol/LPG conversions<br />

on vessels. At the time, they told us of<br />

a detail that is also suitable for lagoons<br />

and bays at these latitudes (Venice,<br />

Scardovari, Marano, Grado), namely<br />

the “particular and specific use in<br />

large fishing farms, where, for moving<br />

between breeding basins, the use<br />

of vessels with LPG-powered engines<br />

contributes to maintaining clean waters<br />

for a more valuable and higher<br />

quality catch.” So, the gazebo of Autogas,<br />

owned by Ecomotive Solutions,<br />

could not be missing. They confirm<br />

us that they are there to incentivise the<br />

retrofitting system of outboard/inboard<br />

petrol-powered vessels that have been<br />

fully converted to LPG. The kits, which<br />

are definitely inexpensive, comply with<br />

the regulations drawn up by the Ministry<br />

of Transports, and are available<br />

both with fixed on-board cylinders and<br />

with transportable cylinders, which are<br />

specially constructed following the automotive<br />

logic, to facilitate refuelling.<br />

Generally, a transportable cylinder cannot<br />

be refuelled at the station because it<br />

has no level and “overflow” indicator,<br />

i.e. it does not stop at 80 percent of its<br />

capacity. This one, on the contrary, has<br />

the same automatic system as a car so,<br />

once it gets to 80 percent, it stops refuelling.<br />

Plus, there is a quick coupling,<br />

clearly designed for boats compatible<br />

with this storage, which is 30 litres.<br />

They tell us of “a 75-litre version that<br />

allows for 8/9 hours of autonomy with<br />

a 60-horsepower outboard engine. The<br />

Venetians are showing interest in this<br />

system. In terms of costs, such conversion<br />

would be around 2,500 euros. We<br />

just did a quick calculation with the<br />

owner of a boat with inboard engine<br />

equipped with two 200-horsepower engines.<br />

By putting 200 litres of LPG on<br />

board, it would cost him around 5,000<br />

euros. And on a boat that consumes 60<br />

litres/hour of petrol...”<br />

18<br />

19

INTERVIEW<br />

#FPTINDUSTRIAL #RECREATIONAL #COMMERCIAL #USA #CHINA<br />

FPT INDUSTRIAL<br />

USA<br />

AND<br />

CHINA<br />

EMBRACING A RED HORIZON...<br />

FPT Industrial’s Red Horizon, a marine integrated electronic<br />

control and monitoring system, was named Gold Winner<br />

of the 2021 edition of the New York Product Design Awards.<br />

Red Horizon was awarded in the Watercraft Category for<br />

successfully consolidating technology, performance, power<br />

and design in a beautiful zero-emission powerboat concept.<br />

Launched in 2019 at the Cannes Yachting Festival, Red<br />

Horizon is FPT Industrial’s integration of the most advanced<br />

marine technologies in engine, monitoring and control<br />

systems. Developed in partnership with two leading global<br />

companies – ZF, a technology supplier of next-generation<br />

mobility systems, and Navico (Simrad), a manufacturer<br />

of marine electronics – Red Horizon guarantees full<br />

navigation control and safety, optimal driving comfort,<br />

and easy handling and harboring. The winning entry was<br />

presented together with the Marine Configuration of the<br />

Cursor X, FPT Industrial’s 4.0 Modular Engine Concept for<br />

a sustainable future. The Red Horizon project is presented<br />

within a unique environment, whose design is inspired by<br />

the automotive world, luxury cars and villas, and vintage<br />

Italian boats, resulting in a comfortable bridge with a touch<br />

of minimalism, where customers can feel at home.<br />

FPT Industrial to conquer the seven<br />

seas. This could be the title<br />

of the interview with Gugliemo<br />

Tummarello, Marine Market<br />

Segment Director. “The development<br />

strategy for marine technology has a<br />

watchword, globalisation, in a dual<br />

meaning: both in terms of product<br />

and in terms of purely geographical<br />

expression,” is the circumstantial confirmation<br />

that comes from Tummarello’s<br />

first statements. “FPT Industrial<br />

initially focused on the European<br />

area, by far the most dynamic, the one<br />

with the highest volumes. Having over<br />

time acquired a significant market<br />

share in the Old Continent, we have<br />

been forced to look at other scenarios,<br />

which for us are still emerging. A renewed<br />

focus on product development,<br />

to adapt the products currently sold in<br />

Europe to overseas markets, was the<br />

necessary step for moving forward.<br />

We have increased the availability of<br />

EPA compliant ratings, with the necessary<br />

adaptations at the data set level<br />

of our engines, to be compliant with<br />

both pleasure and commercial, which<br />

have different regulations. Having<br />

a much more extensive line-up now,<br />

compared to five years ago, we have<br />

built a tailor-made approach for the<br />

FPT Industrial’s marine<br />

applications are<br />

spreading on a global<br />

scale, as witnessed<br />

by the trend in China<br />

and the United States<br />

dealer. This partnership has been in<br />

place for quite some time and has<br />

been waiting for a set of products in<br />

line with the needs of US shipyards<br />

and final users. With a very competitive<br />

portfolio, in a market where innovation<br />

is not only welcome but also<br />

rewarded, if users are supported by<br />

an efficient after sales service. Once<br />

these conditions are met, the Americans<br />

go in search of performance,<br />

sometimes understood as peak power,<br />

sometimes as TCO. In both cases<br />

we stand up to any challenge, whether<br />

it is the power curve for pleasure<br />

boats or low fuel consumption and<br />

torque rise for commercial ones. In<br />

recent years, the American market<br />

has played a key role in growth. As<br />

is often the case, confronted with a<br />

new market, new demands and the<br />

challenges of a different audience,<br />

we have gathered and capitalised on<br />

the feedback from our stakeholders,<br />

which has allowed us to improve the<br />

product globally (American dealers<br />

are MSHS, Stauffer <strong>Diesel</strong> and Madsen<br />

Power, editor’s note).”<br />

It is not only the US that is driving<br />

Fpt’s boom in the marine industry.<br />

Exactly, we have also followed a similar<br />

path in China. Until three years<br />

ago we had no products to position<br />

within the applications that required<br />

CCS emission certification and China<br />

GB15<strong>09</strong>7, which allows navigation<br />

in restricted areas on rivers.<br />

Having corrected the segment of the<br />

range that was most attractive to Chinese<br />

audience, we were able to sell<br />

spot on some projects and become<br />

more noticeable overall in that context.<br />

So when we bade for a tender<br />

that seemed very important to us, we<br />

won it with the N67 570 engine, after<br />

having supplied the engine for a prototype<br />

boat that was the best among<br />

those that participated in that tender.<br />

Eminent, our only Chinese dealer, has<br />

been working with us for decades and<br />

also covers other applications. Specifically,<br />

our 6.7-litre will power some<br />

Ribs, 7.5-metre inflatable boat. The<br />

Chinese market is very particular, as<br />

are its users, because of what we call<br />

the “competitive scenario”, due to a<br />

huge barrier to entry for local manufacturers.<br />

We only go for certain profiles,<br />

where the technological content<br />

is appreciated and the mission is important.<br />

Keel cooling applications are<br />

still at an emerging stage and can be<br />

appreciated in China’s large rivers,<br />

which can show very muddy bottoms.<br />

NEF and Cursor?<br />

The NEF range is the one that typically<br />

drives sales, on average over<br />

70 percent. In the last period, the C9<br />

range, suitably revised and corrected,<br />

is achieving excellent results and together<br />

with the N67 is the best-selling<br />

range in the US, where if you added<br />

up the Cursor and NEF it would result<br />

in a fifty-fifty split, we are growing<br />

significantly compared to the very<br />

good 2021, equally on recreational<br />

and commercial. The only difficulty<br />

that could be on the horizon is the<br />

shortage of boat-side components,<br />

both electronics and precision mechanics,<br />

which could slow down the<br />

industry during 2023.<br />

20<br />

21

H2 - FOCUS<br />

#MANENGINES #DUALFUEL #WORKBOAT #V12X<br />

MAN ENGINES<br />

DUAL<br />

FUEL WITH<br />

MAN Engines V12X: 2200HP<br />

Following on from its most powerful 12-cylinder engine yet,<br />

with 2000 HP, the MAN V12X boasts 30-litre displacement and<br />

2200 HP (1618 kW) at 2300 rpm. In this range, Caterpillar had<br />

accelerated, catching up with mtu (Rolls-Royce Power Systems)<br />

and MAN Engines itself. The ring is always that of Cannes, and now<br />

it’s time again for the Lion’s roar. “The MAN V12X marks the start<br />

of the neXt generation of yacht engines. We are acknowledging<br />

this milestone in engine technology with the new name V12X and<br />

giving the distinctive engine cover an X design. The redesign of the<br />

MAN V12X is accompanied by extra displacement for shipyards.<br />

As always, we have retained the excellent power-to-weight ratio<br />

that MAN engines are known for,” explains Werner Kübler, Head of<br />

Engineering MAN Engines.<br />

HYDROGEN<br />

Werner Kübler, Head of Development at MAN Engines, “What’s special about<br />

our technology is that we use a conventional diesel engine, which doesn’t need<br />

to be optimised for hydrogen.”<br />

Hydrogen follows paths that<br />

are sometimes mysterious,<br />

sometimes linked to the echo<br />

of marketing. MAN Engines<br />

has decided to follow a concerted<br />

path, that of applying dual fuel to a<br />

work boat. “What’s special about our<br />

technology is that we use a conventional<br />

diesel engine, which doesn’t<br />

need to be optimised for hydrogen,”<br />

says Werner Kübler, Head of Development<br />

at MAN Engines. A V12 marine<br />

engine is thus used in which hydrogen<br />

is introduced into the charge<br />

air via an adapter and is added to the<br />

combustion cycle. The combustion<br />

process is thereby started according<br />

to the diesel principle, which requires<br />

the injection of approximately 5% of<br />

diesel fuel. The diesel fuel common<br />

rail injection parameters have been<br />

optimised here for dual fuel operation.<br />

“MAN Engines has long-standing<br />

experience in the development of fuel-saving<br />

and reliable diesel engines,<br />

including for work boats. Building on<br />

this experience, we were also able to<br />

achieve the best consumption values<br />

in dual fuel operation, and ensure<br />

the same operating behaviour as<br />

MAN Engines<br />

conceived a retrofit<br />

of V12 marine diesel<br />

engine, 749 kW output.<br />

It’s the first dual fuel<br />

hydrogen engine in<br />

use on a work boat<br />

displayed by diesel operation at full<br />

load. At the same time, we also reduce<br />

CO 2<br />

tailpipe emissions through<br />

the use of hydrogen by an average<br />

of approx. 50%, and even up to 80%<br />

as a peak value,” adds Kübler. This<br />

is recent news, dated 10 May <strong>2022</strong>,<br />

and stems from MAN Engines’ collaboration<br />

with Windcat Workboats.<br />

These comprise two twelve-cylinder<br />

diesel engines of type MAN D2862<br />

LE448, each with an output of 749<br />

kW (1019 hp) at 2100 rpm. The engines<br />

are IMO Tier III-certified and<br />

equipped with a Selective Catalytic<br />

Reduction exhaust gas aftertreatment<br />

system. Both V12 engines have been<br />

prepared for dual fuel operation by<br />

MAN Engines, and supplemented<br />

with a hydrogen injection system by<br />

development partner CMB.Tech. The<br />

low-emission engine is used on the<br />

world’s first hydrogen-powered crew<br />

transfer vessel (CTV), the “Hydrocat<br />

48” from Windcat Workboats. “By<br />

starting with dual fuel combustion<br />

engines, we can make hydrogen technology<br />

operational in the industry<br />

and kick-start further development<br />

of the technology, regulation, supply<br />

chain etc.,” says Willem van der Wel,<br />

Managing Director of Windcat Workboats.<br />

The D2862, with a cylinder capacity<br />

of 2 litres, is one of the engines that<br />

have written the history of mechanics,<br />

not only in Augsburg but also<br />

in onroad vehicles, stationary power<br />

generation and yacht applications.<br />

MAN Engines offers its customers<br />

and partners solutions like the “MAN<br />

Smart Hybrid Experience” hybrid<br />

system or engines for gas/electric<br />

drives, to contribute to CO 2<br />

reduction<br />

and sustainable shipping. Now that<br />

the MAN D2862 LE448 dual fuel<br />

engines for work boats are ready for<br />

series production, a further milestone<br />

has been reached to that effect.<br />

And here ends the official presentation.<br />

We went a step further and asked<br />

MAN Engines for a little more information<br />

about a promising application.<br />

A technology, that of hydrogen,<br />

which sees Europe, Germany in the<br />

lead, and the United States moving<br />

ahead at a rapid pace, and which<br />

could be the answer to the almost total<br />

hegemony of the Chinese industry<br />

in the world of battery electrics.<br />

Can you explain what the adapter<br />

is and how it works? What does 5%<br />

diesel mean: there is a tank that<br />

delivers 5% of the injection in the<br />

form of diesel and the rest is hydrogen?<br />

Can you explain the injection<br />

and combustion process?<br />

The operating behavior, fuel consumption<br />

and all other characteristics<br />

of the MAN D2862 LE448 Dual<br />

Fuel engine in diesel mode correspond<br />

exactly to the MAN D2862<br />

LE428 with the same performance<br />

(749 kW/1019 hp at 2100 rpm). In<br />

a form of pre-treatment, a precisely<br />

measured quantity of hydrogen is<br />

added to the charge air. This mixture<br />

of hydrogen and air is then ignited<br />

with the injected diesel fuel in the<br />

combustion chamber of the cylinders.<br />

Depending on the engine’s operating<br />

point, only a very small amount of<br />

diesel fuel is needed. On the engine<br />

22<br />

23

H2 - FOCUS<br />

#WINDCAT #SCR # D2862 #HVO<br />

Credits: Windcat Workboats<br />

RENEWABLE FUELS<br />

MAN Engines has approved all marine engines from the current<br />

product range for use with renewable diesel fuel in line with the<br />

standard EN15940 in Europe and the US-American specification<br />

ASTM D975 of the American Society for Testing and Materials. This<br />

will allow customers to replace conventional petroleum-based<br />

diesel fuel with “green” or renewable diesel fuel, obtained from<br />

waste and residues of animal and plant origin, cellulosic biomass<br />

such as crop residues, but also hydrotreated vegetable oils (HVO).<br />

Specifically approved for renewable diesel fuel are the MAN<br />

D2862, D2868 and D2676 series with 12, 8 and 6 cylinders, which<br />

are used in yachts and sport fishing boats as well as work boats.<br />

This includes the full MAN marine engine performance range<br />

from 200 to 2,000 HP (147 to 1,471 kW). They are operated in line<br />

with the emission guidelines issued by EPA, IMO and EU. “With<br />

the approval of marine engines for renewable diesel fuel, MAN<br />

Engines is making an important contribution to sustainability,<br />

both in recreational and professional sailing,” stated Claus Benzler,<br />

Head of Marine MAN Engines. In addition, the combustion of<br />

renewable diesel fuel releases approximately 30% fewer particles<br />

and approximately 10% less nitrogen oxide (NOx). “Renewable<br />

diesel fuel ensures cleaner combustion with fewer emissions.<br />

Despite this, there are neither reductions in performance nor<br />

disadvantages with regard to service and maintenance intervals,”<br />

explained Werner Kübler, Head of Engineering MAN Engines.<br />

test bench, very good values of down<br />

to 5% diesel were achieved, but these<br />

increase in real operation. The diesel<br />

injection parameters are optimized in<br />

dual fuel mode to achieve the lowest<br />

emissions and the best consumption<br />

values. Therefore, in dual fuel mode,<br />

considerably less CO 2<br />

is released in<br />

the exhaust gases in circumstances<br />

where operating behavior and<br />

full load characteristics remain unchanged.<br />

In the event of problems<br />

in the hydrogen circuit or a depleted<br />

hydrogen supply, a switch back to<br />

diesel can be made at any time. This<br />

guarantees uninterrupted operation<br />

with normal reliability. Onboard of<br />

the Hydrocat 48 vessel there are three<br />

H2 stillages modularized from CMB.<br />

Tech. Each has a quantity of 69 kg of<br />

hydrogen. Further, there are two die-<br />

sel tanks with 2,900 litres diesel each<br />

(optional 1,900 litres).<br />

Is the engine otherwise the same:<br />

connecting rods, pistons, common<br />

rail and so on?<br />

MAN V12-2000, YACHT APPLICATION<br />

Beside the interfaces to the hydrogen<br />

system (mechanical as well as electrical),<br />

there are no changes to the<br />

engine. The most important modifications<br />

for optimized operation in dual<br />

fuel mode are on the software-side.<br />

Brand<br />

MAN<br />

Model V12-2000<br />

I. D.<br />

B x S mm - S/B 128 x 157 - 1,23<br />

N. cil. - dm 3 12 - 24,24<br />

Maximum power kW - rpm 1470 - 2.300<br />

Mep at max power bar 32,3<br />

Piston speed m/s 12<br />

Maximum torque Nm - rpm 6.497 - 1.200<br />

Mep at max torque bar 34,4<br />

% power at max torque (kW) 34,2<br />

Torque at max power Nm 6.<strong>09</strong>6<br />

% power at max torque (kW) 55,6 (817)<br />

Work range rpm 1.100<br />

What is the efficiency of D28 when<br />

running on hydrogen?<br />

The efficiency is we reduce CO 2<br />

tailpipe<br />

emissions through the use of<br />

hydrogen by an average of approx.<br />

50%, and even up to 80% as a peak<br />

value. Compared to a pure hydrogen<br />

engine, our dual fuel engine ensures<br />

the operation of the ship even in the<br />

case that hydrogen is not available<br />

on the ship or at the refueling infrastructure.<br />

In terms of effective efficiency,<br />

it can be stated that the delta<br />

diesel to hydrogen in the main driving<br />

range is usually

OFFSHORE<br />

#CIMCOMARINE #RAMAMARINE #ICCB #PHILIPPINES<br />

OFFSHORE<br />

#LAKECONSTANCE #SHAPEUK<br />

#CATERPILLAR #NEWMONT #MINING #ELECTRIFICATION<br />

OXE MARINE<br />

CATCHING<br />

NEW<br />

FANS<br />

From the gearbox, a poly-chain carbon<br />

fiber belt transfers the power directly to<br />

the propeller shaft, eliminating the need<br />

for a conventional bevel gear system.<br />

COX MARINE<br />

AS A COUPLE<br />

ON THE<br />

LAKE<br />

The Lake Constance approval for CXO300 twin<br />

installations is an exception to the standard rule<br />

allowing only a single gasoline outboard up to 100hp.<br />

gines, powered by the “best seller”<br />

OXE150. This engine delivers 150<br />

hp and 380 Nm (280 ft-lb) . With the<br />

high torque gear ratio on the primary<br />

system, the OXE150 delivers up<br />

to 607 Nm (447 ft-lb) of torque on<br />

the propeller shaft. OXE knew from<br />

the start that the commercial marine<br />

market needed something that combined<br />

the endurance and low fuel use<br />

of an inboard stern drive solution<br />

with the flexibility and replaceability<br />

of an outboard.<br />

In US Shamrock Marine repowered<br />

vessel with a twin OXE300 installa-<br />

OXE Marine is<br />

growing worldwide: the<br />

applications are mainly<br />

workboats and tender,<br />

such as the one for<br />

Abramovic’s new yacht<br />

O<br />

XE’s sales network is also<br />

expanding, thanks to the success<br />

met by the range consisting<br />

of the 150, 175, 200<br />

and 300 horsepower, and the 10,000-<br />

hour warranty. For example in Italy,<br />

where dealer Rama Marine unveiled<br />

its partnership with the Studioplast<br />

shipyard at the Venice Boat Show.<br />

The 7.6-metre taxi, powered by an<br />

Oxe 150, will have to contend with<br />

navigating in a delicate urban ecosystem<br />

such as the Venice Lagoon.<br />

A Rigid Hull Inflatable Boat by Avila<br />

Ribs powered by OXE is expected<br />

at the Genoa Boat Show. Also at<br />

the Boat Show in 2021, Imar Boat,<br />

which builds 5.5- to 6.5-metre dinghies,<br />

showed a 6.9-metre with an<br />

OXE200, the livery customised in<br />

the Swedish engine manufacturer’s<br />

colours, anthracite and yellow.<br />

The big shot, however, came from<br />

the Philippines, where OXE Marine<br />

installed 62 outboard diesel ention<br />

for crew boats along the Mississippi<br />

River. It is the company’s first<br />

time using diesel outboards.<br />

And now we move to Ireland, where<br />

the 12m landing craft “Ros Aine”<br />