SUMMER 2023

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

134<br />

THE DISTRIBUTOR’S LINK<br />

BRUNO MARBACHER THREAD-FORMING SCREWS FOR PLASTICS from page 94<br />

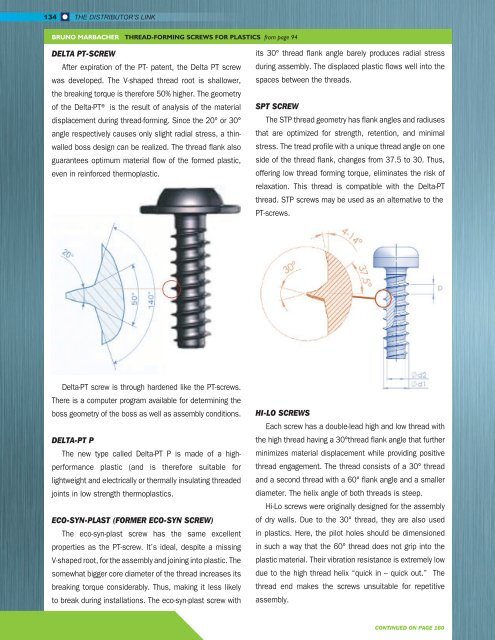

DELTA PT-SCREW<br />

After expiration of the PT- patent, the Delta PT screw<br />

was developed. The V-shaped thread root is shallower,<br />

the breaking torque is therefore 50% higher. The geometry<br />

of the Delta-PT® is the result of analysis of the material<br />

displacement during thread-forming. Since the 20° or 30°<br />

angle respectively causes only slight radial stress, a thinwalled<br />

boss design can be realized. The thread flank also<br />

guarantees optimum material flow of the formed plastic,<br />

even in reinforced thermoplastic.<br />

its 30° thread flank angle barely produces radial stress<br />

during assembly. The displaced plastic flows well into the<br />

spaces between the threads.<br />

SPT SCREW<br />

The STP thread geometry has flank angles and radiuses<br />

that are optimized for strength, retention, and minimal<br />

stress. The tread profile with a unique thread angle on one<br />

side of the thread flank, changes from 37.5 to 30. Thus,<br />

offering low thread forming torque, eliminates the risk of<br />

relaxation. This thread is compatible with the Delta-PT<br />

thread. STP screws may be used as an alternative to the<br />

PT-screws.<br />

Delta-PT screw is through hardened like the PT-screws.<br />

There is a computer program available for determining the<br />

boss geometry of the boss as well as assembly conditions.<br />

DELTA-PT P<br />

The new type called Delta-PT P is made of a highperformance<br />

plastic (and is therefore suitable for<br />

lightweight and electrically or thermally insulating threaded<br />

joints in low strength thermoplastics.<br />

ECO-SYN-PLAST (FORMER ECO-SYN SCREW)<br />

The eco-syn-plast screw has the same excellent<br />

properties as the PT-screw. It’s ideal, despite a missing<br />

V-shaped root, for the assembly and joining into plastic. The<br />

somewhat bigger core diameter of the thread increases its<br />

breaking torque considerably. Thus, making it less likely<br />

to break during installations. The eco-syn-plast screw with<br />

HI-LO SCREWS<br />

Each screw has a double-lead high and low thread with<br />

the high thread having a 30°thread flank angle that further<br />

minimizes material displacement while providing positive<br />

thread engagement. The thread consists of a 30° thread<br />

and a second thread with a 60° flank angle and a smaller<br />

diameter. The helix angle of both threads is steep.<br />

Hi-Lo screws were originally designed for the assembly<br />

of dry walls. Due to the 30° thread, they are also used<br />

in plastics. Here, the pilot holes should be dimensioned<br />

in such a way that the 60° thread does not grip into the<br />

plastic material. Their vibration resistance is extremely low<br />

due to the high thread helix “quick in – quick out.” The<br />

thread end makes the screws unsuitable for repetitive<br />

assembly.<br />

CONTINUED ON PAGE 160