SUMMER 2023

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

Distributor's Link Magazine Summer 2023 / Vol 46 No 3

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

160<br />

THE DISTRIBUTOR’S LINK<br />

BRUNO MARBACHER THREAD-FORMING SCREWS FOR PLASTICS from page 134<br />

PLASTITE SCREWS<br />

They were the first screws that were used specifically<br />

for the direct fastening into plastic parts. The original form<br />

had a tapping screw thread. The thread cross-section<br />

is trilobular. The trilobular thread cross-section permits<br />

relaxation of the plastic in the flat parts of the thread<br />

cross-section during and after assembly. Tensions are<br />

reduced. The risk of stripping is low.<br />

The further development is the Plastite 45 with a 45°<br />

flank angle of the thread. The extra wide thread spacing<br />

and more intense thread angle of PLASTITE® 45 screws<br />

keep induced stress to a minimum during the thread<br />

forming operation.<br />

Plastite 48-2 screws have a trilobular body like Plastite<br />

45 screws, but are furnished with a double lead, two-start<br />

thread. The steeper helix angle allows higher breaking<br />

torque normally resulting in a larger difference between<br />

breaking torque and driving torque.<br />

asymmetrical thread form (10° on the load flank) provides<br />

a low installation torque and very efficient fastening. This<br />

thread design minimizes radial stresses and too much<br />

material displacement.<br />

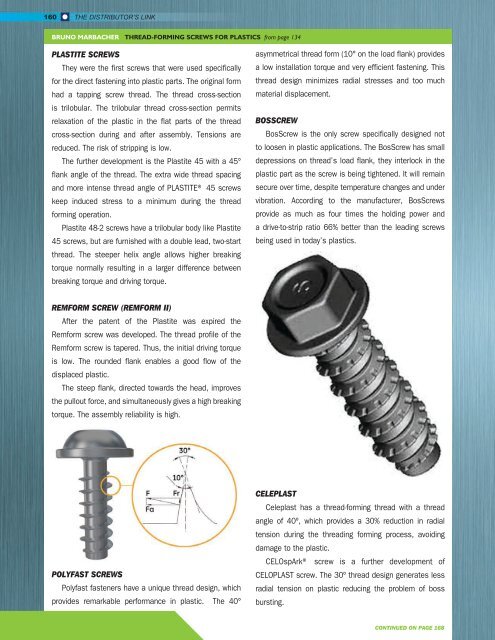

BOSSCREW<br />

BosScrew is the only screw specifically designed not<br />

to loosen in plastic applications. The BosScrew has small<br />

depressions on thread’s load flank, they interlock in the<br />

plastic part as the screw is being tightened. It will remain<br />

secure over time, despite temperature changes and under<br />

vibration. According to the manufacturer, BosScrews<br />

provide as much as four times the holding power and<br />

a drive-to-strip ratio 66% better than the leading screws<br />

being used in today’s plastics.<br />

REMFORM SCREW (REMFORM II)<br />

After the patent of the Plastite was expired the<br />

Remform screw was developed. The thread profile of the<br />

Remform screw is tapered. Thus, the initial driving torque<br />

is low. The rounded flank enables a good flow of the<br />

displaced plastic.<br />

The steep flank, directed towards the head, improves<br />

the pullout force, and simultaneously gives a high breaking<br />

torque. The assembly reliability is high.<br />

POLYFAST SCREWS<br />

Polyfast fasteners have a unique thread design, which<br />

provides remarkable performance in plastic. The 40°<br />

CELEPLAST<br />

Celeplast has a thread-forming thread with a thread<br />

angle of 40º, which provides a 30% reduction in radial<br />

tension during the threading forming process, avoiding<br />

damage to the plastic.<br />

CELOspArk® screw is a further development of<br />

CELOPLAST screw. The 30º thread design generates less<br />

radial tension on plastic reducing the problem of boss<br />

bursting.<br />

CONTINUED ON PAGE 168