You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

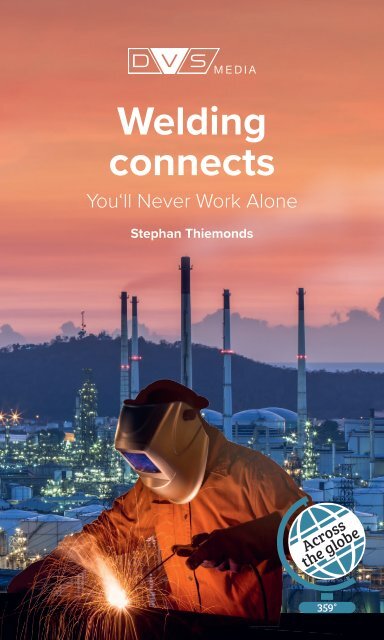

<strong>Welding</strong><br />

connects<br />

You‘ll Never Work Alone<br />

Stephan Thiemonds<br />

Across<br />

the globe<br />

359°

<strong>Welding</strong> connects! Metals and people. Professionally and privately.<br />

Locally and globally.<br />

The author, an educated coppersmith and welder, discovers and<br />

experiences this welding phenomenon again and again during his<br />

professional world travels. Written in the style of Magical Realism<br />

and based on technical and factual knowledge, he tells the story<br />

of welding technology in an entertaining conversational tone. How<br />

and why welding connects; why the healing power of singing while<br />

welding in the middle of a narrow copper pipe brought him as far as<br />

Singapore; from an Antarctic storm night aboard a krill fishing vessel<br />

that was separated, lengthened and welded back together; why<br />

ten little sewage sludge dryers and the archangel Raphael have a<br />

welding connection; and why the return of the Jedi Knights is critical<br />

to the future of welding technology. Surprised by the phenomenon<br />

associated with his profession, that welding not only connects, but<br />

can even fulfill children‘s dreams: through the magic of the welding<br />

industry!<br />

Exceptional reading for industry insiders. Fascinating insights into<br />

the world of welding technology for all industry outsiders.

This book is written by HW (Human Welder), without<br />

the help of AI (Artificial Intelligence).<br />

“<strong>Welding</strong> connects.<br />

Metal and people.<br />

Locally and globally.<br />

Simply phenomenal!”<br />

Internationally valid welding wisdom

Stephan Thiemonds<br />

<strong>Welding</strong> connects<br />

You’ll never work alone

Bibliografic information published<br />

by the Deutsche Nationalbibliothek<br />

The Deutsche Nationalbibliothek lists this publication in<br />

the Deutsche Nationalbibliografie; detailed bibliografic<br />

data are available on the internet at http://dnb.d-nb.de.<br />

Lectorate <strong>Welding</strong> Technology:<br />

Prof. Dr.-Ing. Gerd Kuscher, GSI SLV Hannover,<br />

Achim Hauspurg (SFM), Üdingen<br />

Cover Design by DVS Media, Düsseldorf, Germany.<br />

Inspired by Christian Banpao, Chonburi, Thailand<br />

Copyright Cover: anek.soowannaphoom/Shutterstock<br />

Nuamfolio – stock.adobe.com<br />

robert – stock.adobe.com<br />

TechSolution – stock.adobe.com<br />

ISBN 978-3-96144-197-6<br />

All rights reserved.<br />

© DVS Media GmbH, Düsseldorf 2023<br />

Production: SDL - Digitaler Buchdruck,<br />

Schaltungsdienst Lange oHG, Berlin

Table of Contents<br />

Foreword: <strong>Welding</strong> Technology –<br />

a Field for Creative Minds ............................................ 1<br />

Foreword by the Gesellschaft für Schweißtechnik<br />

International – Schweißtechnische- Lehrund<br />

Versuchsanstalt Hannover, Germany....................... 3<br />

<strong>Welding</strong> connects ........................................................... 5<br />

The healing Power of Singing while <strong>Welding</strong> ............. 14<br />

In Seventh Heaven ..................................................... 120<br />

Mr. Smith and the Thing about Experience ............... 129<br />

The Return of the Jedi Knights .................................. 134<br />

Quick and painless ..................................................... 177<br />

We love the Storms, the roaring Waves ..................... 226<br />

What would the World be without Steel? .................. 280<br />

The Magic of Industry ............................................... 293<br />

Ten small sewage Sludge Dryers and<br />

the Archangel Raphael ............................................... 315<br />

The stainless Steel Thing ........................................... 338<br />

<strong>Welding</strong> connects –<br />

and fulfils Children’s Dreams .................................... 364<br />

You’ll Never Work Alone! ......................................... 382<br />

Take Me Home, Country Roads ................................ 384<br />

The Story Behind 359° .............................................. 389<br />

Sincere Thanks! ......................................................... 391<br />

List of References ...................................................... 395

Foreword: <strong>Welding</strong> Technology – a Field for<br />

Creative Minds<br />

The author acquired his knowledge in Germany. His<br />

professional career is a striking example in the welding<br />

branch: A solid foundation through vocational basics and<br />

advanced training by a dual training system, followed<br />

by international projects worldwide. Exactly like the<br />

DVS – Deutscher Verband für Schweißen und verwandte<br />

Verfahren e. V. (German <strong>Welding</strong> Society) offers with its<br />

training facilities and vocational variants as one of the<br />

great career options.<br />

DVS Media as a subsidiary of DVS – Deutscher Verband<br />

für Schweißen und verwandte Verfahren e. V. is particularly<br />

delighted to publish Mr. Thiemonds’ stories now<br />

also in English.<br />

In his book the author tells in his very personal and unique<br />

way about former projects and his personal encounters<br />

around the world.<br />

His narrative style is inspired by popular culture, like<br />

comics and movies, develops an irresistible suggestive<br />

pull within the professional reader as well as in those<br />

without welding experience, who learn as a pleasant side<br />

effect something about welding and its methods. The<br />

author shares his inner and exterior experience with the<br />

reader. The literary ʻwelding fillerʼ is a good sense of<br />

ʻMagic Realismʼ, interweaving and joining the individual<br />

chapters. Imaginations running wild, but always with the<br />

heartbeat in welding, and furthermore, in engagement in<br />

humanitarian projects like the construction of a school in<br />

Southeast Asia.<br />

1

Not fairy tales told by a welder, not a prank, the stories<br />

are well-founded experience reports, told in a thrilling<br />

way and spiced-up with a good sense of positive thinking<br />

about the world, connecting with people with the same<br />

technical and human mindset. In one of the vividly told<br />

stories about copper tube welding you’ll get to know<br />

about the connection between welding and the healing<br />

power of singing! Showing how to approach and realize<br />

awesome projects together and to grow personally from<br />

this challenge.<br />

For sure, this entertaining and illuminating book by our<br />

ʻmetallograph-philosopherʼ will find a lot of avid readers<br />

around the world. You highly value technique, adventure,<br />

and creativity speeded-up by imagination? – Then you<br />

will love every page of this book!<br />

Uta Tschakert<br />

DVS Media GmbH<br />

2

Foreword by the Gesellschaft für<br />

Schweißtechnik International – Schweißtechnische-<br />

Lehr- und Versuchsanstalt Hannover<br />

(GSI SLV), Germany<br />

Anyone whose mind was once captured by welding technology,<br />

especially laser welding, you can’t get away from<br />

it.<br />

This also happened to the author of this book. His basics<br />

come from conventional welding technology with a solid<br />

education. In his stories he explains in a generally understandable<br />

way what steel is in all its configurations and<br />

how welding technology joins steel. It was deliberately<br />

not intended to be a purely scientific treatise, although all<br />

the statements are technically sound. In addition to all his<br />

practical experience through his worldwide use, the laser,<br />

which joins steel by means of light, plays a major role,<br />

whereby the steel reacts differently in laser beam welding<br />

than is generally known.<br />

Fascinated by this technology, I got to know Stephan<br />

Thiemonds through the company DSI Laserservice<br />

(Thailand), as well as its owner, Mrs. Thongplew Banpao<br />

and the Technical Director, Mr. Thanapol Pradissun. For<br />

many years, I have been auditing DSI Laserservice (Thailand)<br />

for certification according to DIN EN ISO 3834-2.<br />

Through my visits and our cooperation on site, I can<br />

very positively evaluate and recommend the professional<br />

skills of this company. Their qualification and knowledge<br />

benefits all customers of DSI Laserservice (Thailand).<br />

Both at their main location in Chonburi and in the branch<br />

offices. And furthermore, also during mobile laser beam<br />

welding operations on site at the customer’s premises,<br />

3

which is easily possible thanks to the modular, easy-totransport<br />

laser welding systems.<br />

Stephan Thiemonds and the DSI Laserservice (Thailand)<br />

laser specialists know that the possibilities and applications<br />

of a laser beam are far from exhausted. Which in<br />

turn spurs them on to work on innovative further developments<br />

that will ultimately benefit all users of laser<br />

technology, accompanied by the phenomenon of the parttime<br />

welder writing being inspired by his everyday work<br />

to continue to report entertainingly on welding technology<br />

and beyond the industry in future publications.<br />

Based on the industry-related fact that welding connects.<br />

Prof. Dr.-Ing. Gerd Kuscher<br />

Auditor and Accredited Certification<br />

GSI SLV Hannover<br />

4

<strong>Welding</strong> connects!<br />

This simple fact is based on countless proofs. One is<br />

this book that you are holding in your hands right<br />

now. Admittedly, the cover and the pages in between<br />

were not joined together by welding, but by the joining<br />

method ʹgluingʹ described in DIN 8593-8. However, this<br />

book and the stories it contains would simply not exist<br />

without the ʹweldingʹ process described in DIN 1910-<br />

100. Which would not be tragic. But a pity. After all,<br />

this book stands as proof of the fascination associated<br />

with welding. Because welding – attention! – connects<br />

in a double sense: steel and people. Locally and globally.<br />

Isn’t that fantastically!<br />

But before I tell you about the big world of welding<br />

technology out there, I would like to tell you something<br />

small, from inside me: how this book came about.<br />

Even if it should give the impression, there is no wellthought-out<br />

concept behind it. Based on the economically<br />

threatening shortage of skilled workers in Germany, to<br />

increase the attractiveness of welding professions in<br />

an entertaining way. Nor did this book originate from<br />

a beer-social whim with my colleagues in a smoky bar<br />

in Bombay, Bangkok or Butzbach. Inspired by chatting<br />

about old times and deeds done, while someone in the<br />

group euphorically exclaims, Hey, guys, let’s write a history<br />

book about this! This idea excites me, but it doesn’t<br />

hit the real trigger. It merely proves my talent for imagination.<br />

Rather, the trigger I am getting at came very suddenly:<br />

in the form of an emotion popping up. Triggered by an<br />

external circumstance. Detached in a split second. As if<br />

someone had pulled the plug, the emotion – whoosh! –<br />

triggered a flood of inspiration that swept me away, my<br />

body and soul. I experienced a full-body rush of feelings,<br />

ideas, memories and constructs. Coupled with a portion<br />

of digressive fantasy. Based on a solid foundation of factual<br />

and technical knowledge.<br />

5

6<br />

This horny mix of emotions that lasted far longer<br />

than the orgasm experienced in the wildest dreams of<br />

my youth with Brooke Shields (* 1965), – Aahhh! –<br />

together in The Blue Lagoon of Nanuya Levu, – Aahhh!<br />

– damn! What was I trying to tell, anyway? Oh, right.<br />

I was overcome by this very book emotion in a similarly<br />

paradisiacal place in spring 2014: in Thailand.<br />

But unfortunately, not during an erotic bath in front of<br />

a lagoon waterfall. But during working hours. When I<br />

was commissioned by my boss to supervise the repair<br />

of two thin-film evaporator rotors with the experienced<br />

eye of a European welding expert. When the customer<br />

informed me during the initial meeting that the cracks<br />

would not be repaired by the conventional TIG welding<br />

process, as I had originally thought of on the outward<br />

flight above the clouds. Instead, by a laser! That was<br />

the emotion-triggering signal word, whereupon my fantastic<br />

journey into the world of laser welding technology<br />

began. Musically accompanied by the unmistakable Star<br />

Wars opening melody.<br />

“Ta Ta, Ta-da-da Ta, Ta-da-da-da Ta, Tadadada ...”<br />

The rest is history. To be read, in the laser story told<br />

in this book, The Return of the Jedi Knights. I wrote it<br />

while I was still at the DSI in Thailand. After my return<br />

home, this same laser story led me to the Jedi Knight for<br />

further research, Attention! – <strong>Welding</strong> connects – to the<br />

Jedi Knight C. F., at Maulbronn, Baden-Württemberg.<br />

To the Master Yoda of laser welding technology at that<br />

time. To the managing director of the DSI Laserservice<br />

Germany. To his lovely assistant Mrs. Kuzma, to the<br />

bright Mr. Hocke and to other colleagues of his team.<br />

To the, in my eyes, Laser masters of the Universe, who<br />

are fighting for the Good Force. Do laser welding with<br />

courage, discipline and know-how all possible and all<br />

impossible types of steel. Using the fantastic technology<br />

of pulse laser welding, which inspires me to write about<br />

it. With all its unbeatable advantages over conventional<br />

welding processes. Almost without welding distortion

and without changes of microstructure. Narrated in the<br />

story of the same name: Quick and painless.<br />

Another proof that welding connects in a double sense<br />

is my professional boat trip to Antarctica. From Uruguay<br />

to the place where I thought I had fallen out of the world.<br />

Back then, in 2009, on the Norwegian krill trawler Juvel.<br />

On board: two horizontal dryers, each weighing 70 tons.<br />

Designed and built by my colleagues at Buss-SMS-Canzler<br />

workshop in Butzbach. To dry the krill caught in the<br />

Antarctic Ocean, which is immediately processed into<br />

powder on the high seas: into krill flavor. For frozen<br />

pizzas, for example.<br />

For the purpose of plant commissioning, I went<br />

on board with my SMS colleague Ralf in Montevideo.<br />

With him, I moved into a – Attention! – <strong>Welding</strong> connects<br />

especially in the smallest of spaces – a tiny, yet<br />

very cozy cabin with even a porthole. Right at the front<br />

of the ship. Knowing well that a few months earlier the<br />

original boat named Perangi had become the Juvel: in a<br />

colossal transformation at the MWB shipyard in Bremerhaven.<br />

In their dry dock, the Perangi was cut and pushed<br />

apart. After the two krill dryers and other krill processing<br />

machines had been brought below deck and pre-installed,<br />

a nearly 40 meters long, newly manufactured hull section<br />

was placed precisely in the gap. Whereupon all three<br />

hull sections, bow, middle section and stern were pushed<br />

together and, watch out! – <strong>Welding</strong> connects! – were<br />

united in a material bonded manner. By means of two<br />

circular welds running all around the fuselage. Voila! The<br />

transformation of the 60 meters short Perangi into the<br />

99 meters long Juvel was complete.<br />

With this background knowledge, plus my further education<br />

as a European welding expert, who knows from<br />

his own welding experience what undiscovered weld<br />

defects lie dormant in weld seams and what they can do<br />

under alternating stress, we got caught in an Antarctic<br />

storm one night. For hours, the Juvel fought against ten<br />

meters high killer waves. Bow first. Together with my<br />

7

8<br />

colleague and me in our bunks. Steeply we went up the<br />

wave crest. Feet first. High up, at the crest of the wave,<br />

the Juvel paused for a split second. As if she was delaying<br />

the unstoppable on the tipping edge. It took courage –<br />

and then, as a mass of several thousand tons of steel,<br />

plunged into the wave canyon. To fall after ten meters<br />

of free fa- Ahhhh! -ll hit the concrete-hard surface of the<br />

water, Wroommm! – while I stayed in my bunk, frozen<br />

stiff with fear. I clung with both hands to the boards on<br />

the side of my thin mattress, while I pursued only one<br />

thought for hours.<br />

I hope the welds withstand!<br />

Wroommm! –<br />

I hope the welds withstand!<br />

Wroommm! –<br />

Which weld defects lay dormant in the hull joints of the<br />

Juvel, how they got in there and how they were covered<br />

up by the quality department just to meet the deadline for<br />

the hull extension, and whether the welds even held back<br />

to the safe harbor of Montevideo, is revealed in the sailor’s<br />

story, We love the Storms, contained in this book. By<br />

the way, I also sang the pirate song of the same name<br />

of the Bündische youth movement 1 , which I learned as a<br />

little scout at the campfire, on that stormy night. I sang<br />

for hours. While outside, in the pitch dark and surrounded<br />

by icebergs, the sea raged, the waves reared up – to sink<br />

the Juvel with its 52 men strong crew. To avenge the billion-fold<br />

death of the defenseless inhabitants of the Arctic<br />

Ocean, to avenge the krill we had caught and pulverized.<br />

Wroommm! –<br />

To be honest, I wasn’t singing because I enjoyed the<br />

ship-like up-and-down movements. No, no. On the contrary!<br />

I sang to drown out the dark voice of my fear. And<br />

to banish the film of revenge and weld failure haunting<br />

my mind:<br />

“We love the storms, the roaring billows<br />

of the ice-cold winds rough face.

We have sailed so many seas<br />

and yet our flag has not sunk.”<br />

Both as a scout and as a temporary sailor, singing the<br />

chorus loudly gave me the greatest joy. It gave me the<br />

greatest feeling of happiness and thus the least fear of the<br />

big, wide, dark and freezing world outside:<br />

“Heio, heio, heio, heioheioheioho, heiho, heioho,<br />

heiho.”<br />

Just by writing that one line of song, I feel that<br />

pleasant euphoric tingle again. Which leads me recklessly<br />

to reveal to you already that the Juvel did not sink<br />

due to the revenge of the White Krill, nor due to covered-up<br />

welding defects. I’m sure you’ve already figured<br />

that out for yourself, because you have the proof in your<br />

hand right now. If the Juvel had broken apart on the night<br />

of the storm, five days’ voyage from the nearest coast,<br />

the idea I had for the We love the Storms story, which<br />

was born in my bunk when the Juvel hit the surface of<br />

the water, would certainly be lying at the bottom of the<br />

sea now.<br />

Wroommm! –<br />

I would like to use the depth of the last sentence to<br />

advance to the basis of all human and metallic welded<br />

joints. To the material necessary for this: steel. To this<br />

extremely important material that we can no longer<br />

imagine life without today: these miracle-performing<br />

metal alloys of which there are more than 2,500 types<br />

and whose main component is always iron. Before I go<br />

into rapture, which is rather frowned upon in our industry<br />

because it is neither masculine nor standardized, I’ll<br />

quickly come to the worst-case scenario: if there were no<br />

steel, welding would not be able to connect. Neither the<br />

material nor us humans. Which would not only be a pity<br />

in a double sense, but very tragic.<br />

Wroommm! –<br />

Because in a world without steel, my colleagues and<br />

I would be out of a job. We would not only have nothing<br />

9

10<br />

to weld, but also nothing to laugh about. There would be<br />

no thin film evaporators and no krill fishing ship Juvel.<br />

(Which should make the krill very happy, at least.)<br />

There would be no DSI at Thailand, no MWB shipyard<br />

in Bremerhaven, and not even a single, last – oops!<br />

I almost wrote Mohican instead of – which leads me to<br />

the inspiring thought: The last steel worker. – Doesn’t<br />

sound so bad after all. I’ll keep it in mind as a novel<br />

idea. The core of the plot: the long-term preservation<br />

of Germany’s steel industry base in the face of rapidly<br />

emerging, underground competition from Russia, India<br />

and China, which are forming themselves into modern<br />

economical powers.<br />

Back to the facts: Steel is of elementary importance.<br />

Not only for Germany or Europe. For the entire<br />

world. Especially for that of men. Because in a man’s<br />

world without steel, we could neither steel ourselves nor<br />

become as hard as the steel cast at Friedrich Krupp AG<br />

in Essen. Instead of such personality development – from<br />

youth to iron man – we would have to find our way in<br />

the classic male role: as a real German oak. Which, however,<br />

is female by its word type, i.e., its gender word in<br />

traditional German grammar: the oak. Moreover, it has<br />

34 fewer chromosomes than a human being. So why<br />

become a real German oak? To regress in the course of<br />

becoming a man? From 46 chromosomes back to 12? –<br />

Anyway, doesn’t matter.<br />

The main thing is to be a guy like a typical German<br />

heraldic tree. Single-sex, with a strong, towering trunk<br />

and rough bark; a wide-spreading crown that defies<br />

every storm; bearing pendulous inflorescences in spring<br />

and dense deciduous foliage in the middle of the year;<br />

easily recognizable by its fruit: the acorn. Throughout<br />

its long life, the German oak remains faithful to its<br />

God-ordained place in life. With increasing age, it<br />

reverently bends its branches down to its roots. To the<br />

place from which the crown once sprouted. What a real<br />

German oak has to do until someone comes along, cuts

down the indomitable, chops it up and burns in the stove<br />

what has grown slowly over many decades. –<br />

Whoever as a man cannot or does not want to withstand<br />

this classic symbol for eternity, that of the genuine<br />

German oak, could take up residence in Munich’s<br />

motherhouse: the hotel Deutsche Eiche. To warm up<br />

there in the sauna from the cold-metal world of steel.<br />

Thinking of this alternative makes me glad that Mother<br />

nature made a coppersmith out of me! A real metal guy,<br />

an ironman, albeit with an occasional tendency towards<br />

melancholy. Which is not so bad. Because it passes.<br />

Sometimes it’s even productive! Like, for example, my<br />

melancholic streak in combination with a professional<br />

trip to China. When I asked myself the philosophical<br />

question there in 2009: What would the World be without<br />

Steel? Which in turn gave rise to the story of the same<br />

name, also told in this book.<br />

Joy, beautiful spark of Divinity 2 : fortunately for all<br />

of us (but unfortunately for the poor krill) there is steel.<br />

This we welders join together by welding. Which in turn,<br />

as we know, results in human relationships. Because<br />

welding connects. Sometimes consciously, sometimes<br />

surprisingly. Anyone can get caught. And anywhere. You<br />

just have to get involved. To the person. To the welding.<br />

To the steel. Whether local or global. It doesn’t matter.<br />

But always phenomenal.<br />

Having pretty much reached the end of this introductory<br />

narrative, I am once again left with nothing but<br />

hope. Similar to that time, the Antarctic storm night. But<br />

this time my hope is not directed at Zeus and his brother<br />

Poseidon; not at the patron saint of welders and the<br />

patron saint of the sea. No, this time my hope is for you,<br />

dear reader. In the sense that I hope you will immerse<br />

yourself body and soul, whole-body and holistically, in<br />

the following welding stories. Which I would be particularly<br />

pleased about if you do not, I repeat and put it<br />

in capital letters for the sake of importance, if you are<br />

NOT a native of welding. But nevertheless, let yourself<br />

11

e infected by the subject matter and carried away by the<br />

pull of the stories.<br />

And maybe even, not to say hopefully, you will fall<br />

for the fascination of welding while reading. – From<br />

one moment to the next you feel fantastic. Included in a<br />

global community. Closely connected in harmony. You<br />

will feel a pleasantly tingling, aphrodisiac feeling of<br />

connection that will stay with you for a long time. Long<br />

after you have gently closed this book at its end in serene<br />

composure. –<br />

If that’s the case, then hooray! Then my very first emotion<br />

that overcame me back then in Thailand, at the signal<br />

words laser welding, was not only doubly but triply<br />

worthwhile. Because this book, thanks to your added<br />

sense of connection, takes on a hitherto undreamed-of<br />

dimension: a third! Because it is proof that welding also<br />

creates interdisciplinary connections. The best example<br />

is: <strong>Welding</strong> even fulfils children’s dreams! This fantastic<br />

story is also told in this book.<br />

<strong>Welding</strong> connects! You, and me, and somehow all of<br />

us. That’s how Mother Nature intended it for us. And this<br />

is how the poet of the German Enlightenment, the mastermind<br />

of the new self-confidence of the bourgeoisie,<br />

Gotthold Ephraim Lessing (1759 – 1805), wrote it.<br />

“In nature everything is connected with everything<br />

else; everything crosses itself, everything changes<br />

with everything else, everything changes, one into the<br />

other.”<br />

Wroommm! –<br />

Across the world somewhere on the way,<br />

in spring 2023<br />

12

Endnotes<br />

1 German elitist youth movement after Word War I with focus on<br />

the male ideal of a knight and the medieval orders of knights,<br />

supporting a lifelong brotherhood of the carefully selected members.<br />

2 Joy, beautiful Spark of Divinity is the first line of Friedrich<br />

Schiller’s (1759 – 1805) most famous poem, Ode to joy. It was<br />

written in the summer of 1785 and was set to music by Ludwig<br />

van Beethoven (1770 – 1827), among others, in the 4th movement<br />

of his 9th Symphony.<br />

13

14<br />

The healing Power of Singing while<br />

<strong>Welding</strong><br />

Just two years after completing my vocational training,<br />

I was allowed to fly to Singapore on business at the<br />

tender age of 21. Business class above the clouds to the<br />

other end of the world. To the Southeast Asian island<br />

city-state not far from the equator, where – my self-confidence<br />

could hardly believe it – they needed me and my<br />

skills as a coppersmith. Among all my experienced Canzler<br />

3 colleagues, I was the one who received the plane<br />

ticket from the boss. Including his confidence that I was<br />

exactly the right man for this mission. There were two<br />

simple but travel-decisive reasons for this.<br />

First of all, I was slim and slender, in comparison to<br />

my colleagues, who were also capable of copper welding<br />

and were far more experienced. Physically, I did not<br />

correspond to the classic image of a strong coppersmith<br />

who could easily swing a sledgehammer. At least I was<br />

willing. And I knew that although I didn’t have the<br />

strength of an ironman forged from Krupp steel, I did<br />

have the courage of a dreamer. The second reason was:<br />

I was not only learning to weld, but also to sing while<br />

welding. And I did it without being ashamed of it. Thus,<br />

I had two key qualifications – being lanky and able to<br />

sing – that the training framework did not provide for<br />

teaching. This deficiency was my all-important advantage.<br />

Sounds confusing, I know. Almost like an engineer’s-fairytale<br />

like from the Thousand and One Nights.<br />

So, let me tell it to you.<br />

Once upon a time, more than 100 years ago, there was<br />

a master coppersmith named Carl Canzler (1858–1919).<br />

He operated a coppersmithing bearing his name, which<br />

he founded in 1890 and which was located in the north<br />

of the district town of Düren, in North Rhine-Westphalia.<br />

In his work as an apparatus engineer, the entrepreneur<br />

was confronted with the enormous problems of welding<br />

copper. In his search for a welding solution, he combined

his ambitious enthusiasm for research with the tinkering<br />

talents of his employee and Master craftsman, Richard<br />

Samesreuther (1880 – 1946). This clever ʹYou’ll Never<br />

Work Alone!ʹ-teamwork led them to a groundbreaking<br />

invention in welding technology. Patented by the Imperial<br />

Patent Office on October 01, 1912 with the following<br />

wording:<br />

“Process for autogenous welding of copper, using a<br />

phosphorus-containing copper wire as filler material.”<br />

The Canzler wire, named after Carl Canzler’s family<br />

and company name and soon world-famous for its<br />

welding advantages, was invented. But his wire was not<br />

only suitable for welding copper. In contrast to the previous<br />

brazing, it also made acid-resistant welds possible.<br />

Due to the turmoil of the First World War, the paths of<br />

the two patent holders diverged. While Carl Canzler continued<br />

to build up the coppersmith’s workshop in Düren<br />

with the help of his son Heinrich, Richard Samesreuther<br />

went to Butzbach as a 38-year-old returning war veteran.<br />

There, on April 9, 1919, he had the establishment of the<br />

apparatus construction company Samesreuther & Co.<br />

OHG entered in the Commercial Register at the Hessian<br />

District Court.<br />

What no one could have foreseen at that time: In the<br />

following decades and as a result of economic changes,<br />

what once separated was to be reunited. The Swiss steel<br />

and mechanical engineering company Buss AG and Mr.<br />

Müller and Mr. Schuss played a decisive role in the decades-long<br />

reunification. Incidentally, their initials, M<br />

and S, stand for SMS, following the S for Samesreuther.<br />

They were joined by ʹthe Canzlerʹ from Düren, from<br />

which Buss-SMS-Canzler GmbH was finally formed in<br />

2003. This company celebrated its 100th anniversary<br />

on April 9, 2019, on the origins company premises in<br />

Butzbach, thus miraculously closing the circle. As an<br />

15