EPP Europe P2.2023

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

» PCB & ASSEMBLY<br />

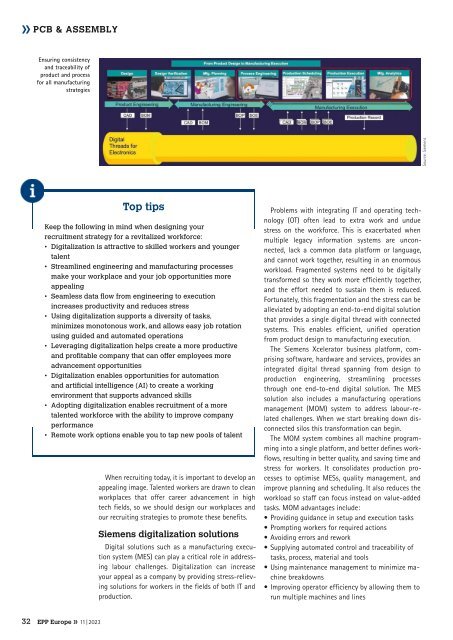

Ensuring consistency<br />

and traceability of<br />

product and process<br />

for all manufacturing<br />

strategies<br />

Source: Siemens<br />

Top tips<br />

Keep the following in mind when designing your<br />

recruitment strategy for a revitalized workforce:<br />

• Digitalization is attractive to skilled workers and younger<br />

talent<br />

• Streamlined engineering and manufacturing processes<br />

make your workplace and your job opportunities more<br />

appealing<br />

• Seamless data flow from engineering to execution<br />

increases productivity and reduces stress<br />

• Using digitalization supports a diversity of tasks,<br />

minimizes monotonous work, and allows easy job rotation<br />

using guided and automated operations<br />

• Leveraging digitalization helps create a more productive<br />

and profitable company that can offer employees more<br />

advancement opportunities<br />

• Digitalization enables opportunities for automation<br />

and artificial intelligence (AI) to create a working<br />

environment that supports advanced skills<br />

• Adopting digitalization enables recruitment of a more<br />

talented workforce with the ability to improve company<br />

performance<br />

• Remote work options enable you to tap new pools of talent<br />

When recruiting today, it is important to develop an<br />

appealing image. Talented workers are drawn to clean<br />

workplaces that offer career advancement in high<br />

tech fields, so we should design our workplaces and<br />

our recruiting strategies to promote these benefits.<br />

Siemens digitalization solutions<br />

Digital solutions such as a manufacturing execution<br />

system (MES) can play a critical role in addressing<br />

labour challenges. Digitalization can increase<br />

your appeal as a company by providing stress-relieving<br />

solutions for workers in the fields of both IT and<br />

production.<br />

Problems with integrating IT and operating technology<br />

(OT) often lead to extra work and undue<br />

stress on the workforce. This is exacerbated when<br />

multiple legacy information systems are unconnected,<br />

lack a common data platform or language,<br />

and cannot work together, resulting in an enormous<br />

workload. Fragmented systems need to be digitally<br />

transformed so they work more efficiently together,<br />

and the effort needed to sustain them is reduced.<br />

Fortunately, this fragmentation and the stress can be<br />

alleviated by adopting an end-to-end digital solution<br />

that provides a single digital thread with connected<br />

systems. This enables efficient, unified operation<br />

from product design to manufacturing execution.<br />

The Siemens Xcelerator business platform, comprising<br />

software, hardware and services, provides an<br />

integrated digital thread spanning from design to<br />

production engineering, streamlining processes<br />

through one end-to-end digital solution. The MES<br />

solution also includes a manufacturing operations<br />

management (MOM) system to address labour-related<br />

challenges. When we start breaking down disconnected<br />

silos this transformation can begin.<br />

The MOM system combines all machine programming<br />

into a single platform, and better defines workflows,<br />

resulting in better quality, and saving time and<br />

stress for workers. It consolidates production processes<br />

to optimise MESs, quality management, and<br />

improve planning and scheduling. It also reduces the<br />

workload so staff can focus instead on value-added<br />

tasks. MOM advantages include:<br />

• Providing guidance in setup and execution tasks<br />

• Prompting workers for required actions<br />

• Avoiding errors and rework<br />

• Supplying automated control and traceability of<br />

tasks, process, material and tools<br />

• Using maintenance management to minimize machine<br />

breakdowns<br />

• Improving operator efficiency by allowing them to<br />

run multiple machines and lines<br />

32 <strong>EPP</strong> <strong>Europe</strong> » 11 | 2023