EPP Europe P2.2023

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

» PCB & ASSEMBLY<br />

Source: ArtiMinds Robotics<br />

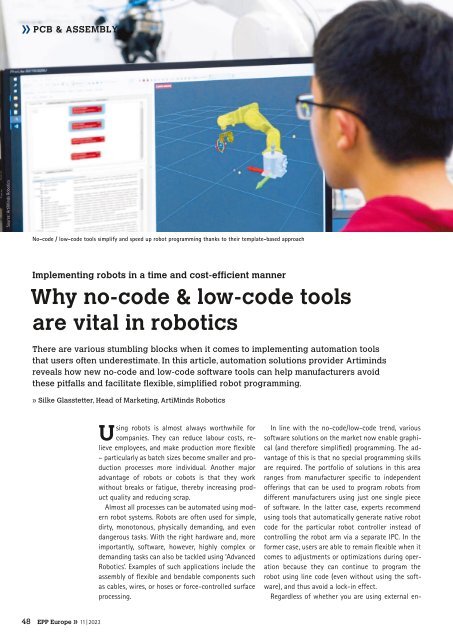

No-code / low-code tools simplify and speed up robot programming thanks to their template-based approach<br />

Implementing robots in a time and cost-efficient manner<br />

Why no-code & low-code tools<br />

are vital in robotics<br />

There are various stumbling blocks when it comes to implementing automation tools<br />

that users often underestimate. In this article, automation solutions provider Artiminds<br />

reveals how new no-code and low-code software tools can help manufacturers avoid<br />

these pitfalls and facilitate flexible, simplified robot programming.<br />

» Silke Glasstetter, Head of Marketing, ArtiMinds Robotics<br />

Using robots is almost always worthwhile for<br />

companies. They can reduce labour costs, relieve<br />

employees, and make production more flexible<br />

– particularly as batch sizes become smaller and production<br />

processes more individual. Another major<br />

advantage of robots or cobots is that they work<br />

without breaks or fatigue, thereby increasing product<br />

quality and reducing scrap.<br />

Almost all processes can be automated using modern<br />

robot systems. Robots are often used for simple,<br />

dirty, monotonous, physically demanding, and even<br />

dangerous tasks. With the right hardware and, more<br />

importantly, software, however, highly complex or<br />

demanding tasks can also be tackled using ‘Advanced<br />

Robotics’. Examples of such applications include the<br />

assembly of flexible and bendable components such<br />

as cables, wires, or hoses or force-controlled surface<br />

processing.<br />

In line with the no-code/low-code trend, various<br />

software solutions on the market now enable graphical<br />

(and therefore simplified) programming. The advantage<br />

of this is that no special programming skills<br />

are required. The portfolio of solutions in this area<br />

ranges from manufacturer specific to independent<br />

offerings that can be used to program robots from<br />

different manufacturers using just one single piece<br />

of software. In the latter case, experts recommend<br />

using tools that automatically generate native robot<br />

code for the particular robot controller instead of<br />

controlling the robot arm via a separate IPC. In the<br />

former case, users are able to remain flexible when it<br />

comes to adjustments or optimizations during operation<br />

because they can continue to program the<br />

robot using line code (even without using the software),<br />

and thus avoid a lock-in effect.<br />

Regardless of whether you are using external en-<br />

48 <strong>EPP</strong> <strong>Europe</strong> » 11 | 2023