Single pull macgregor type hatch cover.pdf - Cochin University of ...

Single pull macgregor type hatch cover.pdf - Cochin University of ...

Single pull macgregor type hatch cover.pdf - Cochin University of ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

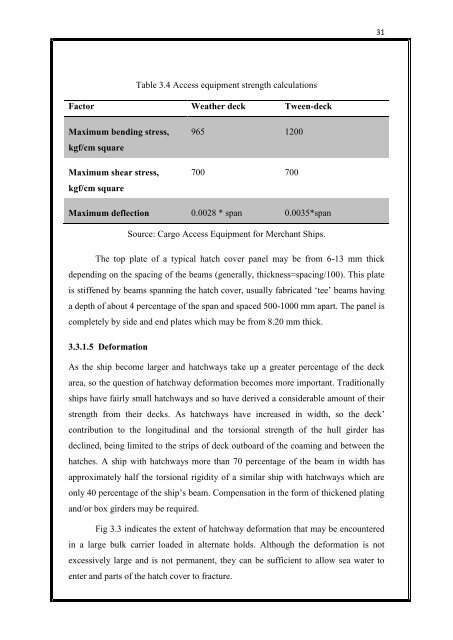

Table 3.4 Access equipment strength calculations<br />

Factor Weather deck Tween-deck<br />

Maximum bending stress,<br />

kgf/cm square<br />

Maximum shear stress,<br />

kgf/cm square<br />

965 1200<br />

700 700<br />

Maximum deflection 0.0028 * span 0.0035*span<br />

Source: Cargo Access Equipment for Merchant Ships.<br />

The top plate <strong>of</strong> a typical <strong>hatch</strong> <strong>cover</strong> panel may be from 6-13 mm thick<br />

depending on the spacing <strong>of</strong> the beams (generally, thickness=spacing/100). This plate<br />

is stiffened by beams spanning the <strong>hatch</strong> <strong>cover</strong>, usually fabricated ‘tee’ beams having<br />

a depth <strong>of</strong> about 4 percentage <strong>of</strong> the span and spaced 500-1000 mm apart. The panel is<br />

completely by side and end plates which may be from 8.20 mm thick.<br />

3.3.1.5 Deformation<br />

As the ship become larger and <strong>hatch</strong>ways take up a greater percentage <strong>of</strong> the deck<br />

area, so the question <strong>of</strong> <strong>hatch</strong>way deformation becomes more important. Traditionally<br />

ships have fairly small <strong>hatch</strong>ways and so have derived a considerable amount <strong>of</strong> their<br />

strength from their decks. As <strong>hatch</strong>ways have increased in width, so the deck’<br />

contribution to the longitudinal and the torsional strength <strong>of</strong> the hull girder has<br />

declined, being limited to the strips <strong>of</strong> deck outboard <strong>of</strong> the coaming and between the<br />

<strong>hatch</strong>es. A ship with <strong>hatch</strong>ways more than 70 percentage <strong>of</strong> the beam in width has<br />

approximately half the torsional rigidity <strong>of</strong> a similar ship with <strong>hatch</strong>ways which are<br />

only 40 percentage <strong>of</strong> the ship’s beam. Compensation in the form <strong>of</strong> thickened plating<br />

and/or box girders may be required.<br />

Fig 3.3 indicates the extent <strong>of</strong> <strong>hatch</strong>way deformation that may be encountered<br />

in a large bulk carrier loaded in alternate holds. Although the deformation is not<br />

excessively large and is not permanent, they can be sufficient to allow sea water to<br />

enter and parts <strong>of</strong> the <strong>hatch</strong> <strong>cover</strong> to fracture.<br />

31