You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

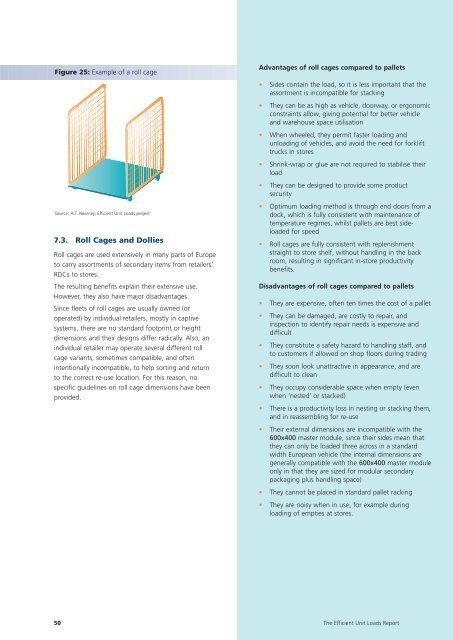

Figure 25: Example of a roll cage<br />

Source: A.T. Kearney, Efficient Unit Loads project<br />

7.3. Roll Cages and Dollies<br />

Roll cages are used extensively in many parts of Europe<br />

to carry assortments of secondary items from retailers’<br />

RDCs to stores.<br />

The resulting benefits explain their extensive use.<br />

However, they also have major disadvantages.<br />

Since fleets of roll cages are usually owned (or<br />

operated) by individual retailers, mostly in captive<br />

systems, there are no standard footprint or height<br />

dimensions and their designs differ radically. Also, an<br />

individual retailer may operate several different roll<br />

cage variants, sometimes compatible, and often<br />

intentionally incompatible, to help sorting and return<br />

to the correct re-use location. For this reason, no<br />

specific guidelines on roll cage dimensions have been<br />

provided.<br />

50<br />

Advantages of roll cages compared to pallets<br />

• Sides contain the load, so it is less important that the<br />

assortment is incompatible for stacking<br />

• They can be as high as vehicle, doorway, or ergonomic<br />

constraints allow, giving potential for better vehicle<br />

and warehouse space utilisation<br />

• When wheeled, they permit faster loading and<br />

unloading of vehicles, and avoid the need for forklift<br />

trucks in stores<br />

• Shrink-wrap or glue are not required to stabilise their<br />

load<br />

• They can be designed to provide some product<br />

security<br />

• Optimum loading method is through end doors from a<br />

dock, which is fully consistent with maintenance of<br />

temperature regimes, whilst pallets are best sideloaded<br />

for speed<br />

• Roll cages are fully consistent with replenishment<br />

straight to store shelf, without handling in the back<br />

room, resulting in significant in-store productivity<br />

benefits.<br />

Disadvantages of roll cages compared to pallets<br />

• They are expensive, often ten times the cost of a pallet<br />

• They can be damaged, are costly to repair, and<br />

inspection to identify repair needs is expensive and<br />

difficult<br />

• They constitute a safety hazard to handling staff, and<br />

to customers if allowed on shop floors during trading<br />

• They soon look unattractive in appearance, and are<br />

difficult to clean<br />

• They occupy considerable space when empty (even<br />

when ‘nested’ or stacked)<br />

• There is a productivity loss in nesting or stacking them,<br />

and in reassembling for re-use<br />

• Their external dimensions are incompatible with the<br />

600x400 master module, since their sides mean that<br />

they can only be loaded three across in a standard<br />

width European vehicle (the internal dimensions are<br />

generally compatible with the 600x400 master module<br />

only in that they are sized for modular secondary<br />

packaging plus handling space)<br />

• They cannot be placed in standard pallet racking<br />

• They are noisy when in use, for example during<br />

loading of empties at stores.<br />

The Efficient Unit Loads Report