Selection and Testing of Electronic Components for LM

Selection and Testing of Electronic Components for LM

Selection and Testing of Electronic Components for LM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

100<br />

Type <strong>of</strong> check<br />

Type <strong>of</strong> component Me- En- El.<br />

chan- viron- param.<br />

ical mental<br />

Resistors, resistor net<br />

works <strong>and</strong> potentio<br />

meters S S<br />

Capacitors<br />

Diodes, transistors<br />

S S<br />

<strong>and</strong> thyristors S A<br />

Micro circuits S A A<br />

Table 1<br />

<strong>Testing</strong> <strong>of</strong> components<br />

A Check <strong>of</strong> the whole consignment<br />

S Sampling test in accordance with MIL-STD-105<br />

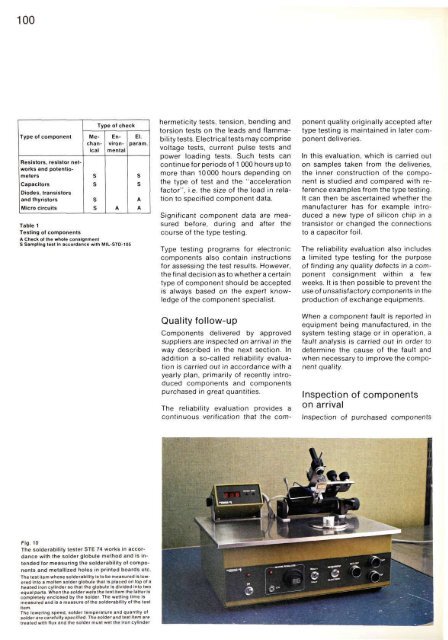

Fig. 10<br />

The solderability tester STE 74 works in accordance<br />

with the solder globule method <strong>and</strong> is intended<br />

<strong>for</strong> measuring the solderability <strong>of</strong> components<br />

<strong>and</strong> metallized holes in printed boards etc.<br />

The test Item whose solderability is to be measured is lowered<br />

into a molten solder globule that is placed on top <strong>of</strong> a<br />

heated iron cylinder so that the globule Is divided into two<br />

equal parts. When the solder wets the test item the latter is<br />

completely enclosed by the solder. The wetting time is<br />

measured <strong>and</strong> Is a measure <strong>of</strong> the solderability <strong>of</strong> the test<br />

item.<br />

The lowering speed, solder temperature <strong>and</strong> quantity <strong>of</strong><br />

solder are carefully specified. The solder <strong>and</strong> test item are<br />

treated with flux <strong>and</strong> the solder must wet the iron cylinder<br />

hermeticity tests, tension, bending <strong>and</strong><br />

torsion tests on the leads <strong>and</strong> flammabil<br />

ity tests. Electrical tests may com prise<br />

voltage tests, current pulse tests <strong>and</strong><br />

power loading tests. Such tests can<br />

continue <strong>for</strong> periods <strong>of</strong> 1 000 hours up to<br />

more than 10000 hours depending on<br />

the type <strong>of</strong> test <strong>and</strong> the "acceleration<br />

factor", i.e. the size <strong>of</strong> the load in relation<br />

to specified component data.<br />

Significant component data are measured<br />

be<strong>for</strong>e, during <strong>and</strong> after the<br />

course <strong>of</strong> the type testing.<br />

Type testing programs <strong>for</strong> electronic<br />

components also contain instructions<br />

<strong>for</strong> assessing the test results. However,<br />

the final decision as to whether a certain<br />

type <strong>of</strong> component should be accepted<br />

is always based on the expert knowledge<br />

<strong>of</strong> the component specialist.<br />

Quality follow-up<br />

<strong>Components</strong> delivered by approved<br />

suppliers are inspected on arrival in the<br />

way described in the next section. In<br />

addition a so-called reliability evaluation<br />

is carried out in accordance with a<br />

yearly plan, primarily <strong>of</strong> recently introduced<br />

components <strong>and</strong> components<br />

purchased in great quantities.<br />

The reliability evaluation provides a<br />

continuous verification that the com<br />

ponent quality originally accepted after<br />

type testing is maintained in later component<br />

deliveries.<br />

In this evaluation, which is carried out<br />

on samples taken from the deliveries,<br />

the inner construction <strong>of</strong> the component<br />

is studied <strong>and</strong> compared with reference<br />

examples from the type testing.<br />

It can then be ascertained whether the<br />

manufacturer has <strong>for</strong> example introduced<br />

a new type <strong>of</strong> silicon chip in a<br />

transistor or changed the connections<br />

to a capacitor foil.<br />

The reliability evaluation also includes<br />

a limited type testing <strong>for</strong> the purpose<br />

<strong>of</strong> finding any quality defects in a component<br />

consignment within a few<br />

weeks. It is then possible to prevent the<br />

use <strong>of</strong> unsatisfactory components in the<br />

production <strong>of</strong> exchange equipments.<br />

When a component fault is reported in<br />

equipment being manufactured, in the<br />

system testing stage or in operation, a<br />

fault analysis is carried out in order to<br />

determine the cause <strong>of</strong> the fault <strong>and</strong><br />

when necessary to improve the component<br />

quality.<br />

Inspection <strong>of</strong> components<br />

on arrival<br />

Inspection <strong>of</strong> purchased components