Selection and Testing of Electronic Components for LM

Selection and Testing of Electronic Components for LM

Selection and Testing of Electronic Components for LM

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

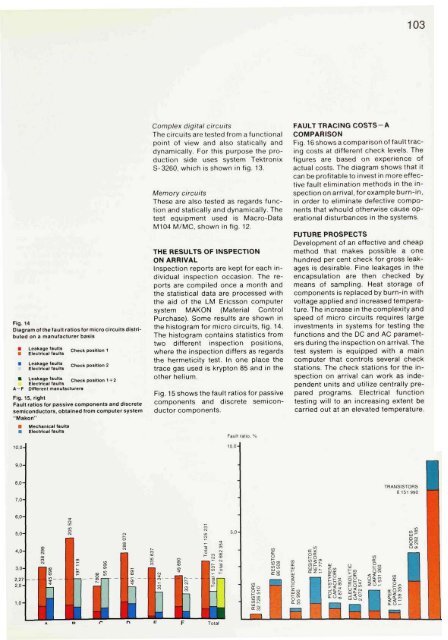

Fig. 14<br />

Diagram <strong>of</strong> the fault ratios <strong>for</strong> micro circuits distributed<br />

on a manufacturer basis<br />

Leakage faults check position 1<br />

Electrical faults<br />

Leakage faults<br />

Electrical faults<br />

Cneck ,,,„„ 2<br />

Leakage faults<br />

Electrical faults<br />

check pos|tlon , + 2<br />

Different manufacturers<br />

Fig. 15, right<br />

Fault ratios <strong>for</strong> passive components <strong>and</strong> discrete<br />

semiconductors, obtained from computer system<br />

"Makon"<br />

Mechanical faults<br />

Electrical faults<br />

Complex digital circuits<br />

The circuits are tested from a functional<br />

point <strong>of</strong> view <strong>and</strong> also statically <strong>and</strong><br />

dynamically. For this purpose the production<br />

side uses system Tektronix<br />

S-3260, which is shown in fig. 13.<br />

Memory circuits<br />

These are also tested as regards function<br />

<strong>and</strong> statically <strong>and</strong> dynamically. The<br />

test equipment used is Macro-Data<br />

M104 M/MC, shown in fig. 12.<br />

THE RESULTS OF INSPECTION<br />

ON ARRIVAL<br />

Inspection reports are kept <strong>for</strong> each individual<br />

inspection occasion. The reports<br />

are compiled once a month <strong>and</strong><br />

the statistical data are processed with<br />

the aid <strong>of</strong> the <strong>LM</strong> Ericsson computer<br />

system MAKON (Material Control<br />

Purchase). Some results are shown in<br />

the histogram <strong>for</strong> micro circuits, fig. 14.<br />

The histogram contains statistics from<br />

two different inspection positions,<br />

where the inspection differs as regards<br />

the hermeticity test. In one place the<br />

trace gas used is krypton 85 <strong>and</strong> in the<br />

other helium.<br />

Fig. 15 shows the fault ratios <strong>for</strong> passive<br />

components <strong>and</strong> discrete semiconductor<br />

components.<br />

103<br />

FAULT TRACING COSTS-A<br />

COMPARISON<br />

Fig. 16 shows a comparison <strong>of</strong> fault tracing<br />

costs at different check levels. The<br />

figures are based on experience <strong>of</strong><br />

actual costs. The diagram shows that it<br />

can be pr<strong>of</strong>itable to invest in more effective<br />

fault elimination methods in the inspection<br />

on arrival, <strong>for</strong>example burn-in,<br />

in order to eliminate defective components<br />

that whould otherwise cause operational<br />

disturbances in the systems.<br />

FUTURE PROSPECTS<br />

Development <strong>of</strong> an effective <strong>and</strong> cheap<br />

method that makes possible a one<br />

hundred per cent check <strong>for</strong> gross leakages<br />

is desirable. Fine leakages in the<br />

encapsulation are then checked by<br />

means <strong>of</strong> sampling. Heat storage <strong>of</strong><br />

components is replaced by burn-in with<br />

voltage applied <strong>and</strong> increased temperature.<br />

The increase in the complexity <strong>and</strong><br />

speed <strong>of</strong> micro circuits requires large<br />

investments in systems <strong>for</strong> testing the<br />

functions <strong>and</strong> the DC <strong>and</strong> AC parameters<br />

during the inspection on arrival. The<br />

test system is equipped with a main<br />

computer that controls several check<br />

stations. The check stations <strong>for</strong> the inspection<br />

on arrival can work as independent<br />

units <strong>and</strong> utilize centrally prepared<br />

programs. Electrical function<br />

testing will to an increasing extent be<br />

carried out at an elevated temperature.