An innovative greywater treatment system for urban areas ... - SuSanA

An innovative greywater treatment system for urban areas ... - SuSanA

An innovative greywater treatment system for urban areas ... - SuSanA

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

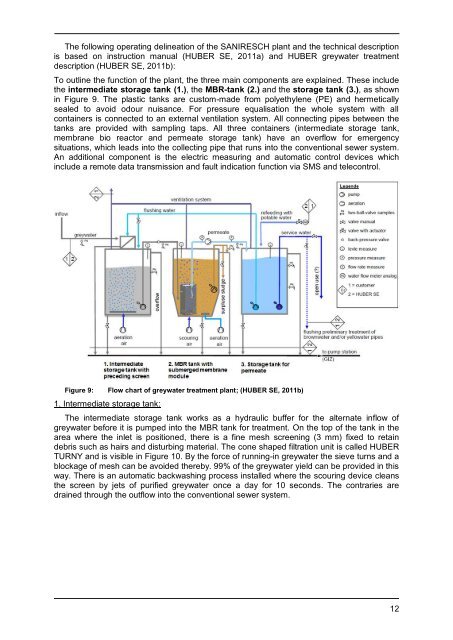

The following operating delineation of the SANIRESCH plant and the technical description<br />

is based on instruction manual (HUBER SE, 2011a) and HUBER <strong>greywater</strong> <strong>treatment</strong><br />

description (HUBER SE, 2011b):<br />

To outline the function of the plant, the three main components are explained. These include<br />

the intermediate storage tank (1.), the MBR-tank (2.) and the storage tank (3.), as shown<br />

in Figure 9. The plastic tanks are custom-made from polyethylene (PE) and hermetically<br />

sealed to avoid odour nuisance. For pressure equalisation the whole <strong>system</strong> with all<br />

containers is connected to an external ventilation <strong>system</strong>. All connecting pipes between the<br />

tanks are provided with sampling taps. All three containers (intermediate storage tank,<br />

membrane bio reactor and permeate storage tank) have an overflow <strong>for</strong> emergency<br />

situations, which leads into the collecting pipe that runs into the conventional sewer <strong>system</strong>.<br />

<strong>An</strong> additional component is the electric measuring and automatic control devices which<br />

include a remote data transmission and fault indication function via SMS and telecontrol.<br />

Figure 9: Flow chart of <strong>greywater</strong> <strong>treatment</strong> plant; (HUBER SE, 2011b)<br />

1. Intermediate storage tank:<br />

The intermediate storage tank works as a hydraulic buffer <strong>for</strong> the alternate inflow of<br />

<strong>greywater</strong> be<strong>for</strong>e it is pumped into the MBR tank <strong>for</strong> <strong>treatment</strong>. On the top of the tank in the<br />

area where the inlet is positioned, there is a fine mesh screening (3 mm) fixed to retain<br />

debris such as hairs and disturbing material. The cone shaped filtration unit is called HUBER<br />

TURNY and is visible in Figure 10. By the <strong>for</strong>ce of running-in <strong>greywater</strong> the sieve turns and a<br />

blockage of mesh can be avoided thereby. 99% of the <strong>greywater</strong> yield can be provided in this<br />

way. There is an automatic backwashing process installed where the scouring device cleans<br />

the screen by jets of purified <strong>greywater</strong> once a day <strong>for</strong> 10 seconds. The contraries are<br />

drained through the outflow into the conventional sewer <strong>system</strong>.<br />

12