Regulatory oversight of nuclear safety in Finland. Annual ... - STUK

Regulatory oversight of nuclear safety in Finland. Annual ... - STUK

Regulatory oversight of nuclear safety in Finland. Annual ... - STUK

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4.1 Loviisa NPP<br />

I&C upgrade (LARA) at the Loviisa plant was<br />

postponed until 2014 for Loviisa 1 and until 2016<br />

for Loviisa 2. The systems to be upgraded <strong>in</strong> the<br />

second phase <strong>in</strong>clude the reactor plant I&C systems<br />

most important to <strong>safety</strong> as well as the I&C<br />

systems <strong>of</strong> the ma<strong>in</strong> <strong>safety</strong> functions, such as that<br />

<strong>of</strong> emergency power supply. Postponement <strong>of</strong> the<br />

I&C upgrade requires the licensee to take action<br />

<strong>in</strong> order to ensure the sufficiency <strong>of</strong> ma<strong>in</strong>tenance<br />

operations on the exist<strong>in</strong>g I&C systems and equipment<br />

as well as the availability <strong>of</strong> spare parts.<br />

In the ma<strong>in</strong>, Fortum Power and Heat Oy and its<br />

Loviisa power plant organisation have operated <strong>in</strong> a<br />

systematic and development-oriented way to ensure<br />

the <strong>safety</strong> <strong>of</strong> the plant. The observations made by<br />

<strong>STUK</strong> <strong>in</strong> the course <strong>of</strong> its <strong>oversight</strong> <strong>in</strong>dicate that<br />

the organisation produces an abundance <strong>of</strong> <strong>in</strong>formation<br />

regard<strong>in</strong>g its operations, but this <strong>in</strong>formation<br />

is not fully utilised for develop<strong>in</strong>g the management<br />

system and for improv<strong>in</strong>g operations. The work for<br />

improv<strong>in</strong>g the operational processes <strong>of</strong> the organisation<br />

must be cont<strong>in</strong>ued <strong>in</strong> order to ensure the safe<br />

operation <strong>of</strong> the plant, particularly with regard to<br />

develop<strong>in</strong>g the management system, ensur<strong>in</strong>g the<br />

quality <strong>of</strong> procurement operations and develop<strong>in</strong>g<br />

the <strong>safety</strong> culture assessment methods. The<br />

programme for develop<strong>in</strong>g project management at<br />

the Loviisa power plant has been successfully completed,<br />

but there is further scope for improvement<br />

<strong>in</strong> the quality management <strong>of</strong> project activities.<br />

<strong>STUK</strong> paid attention to the procedures <strong>in</strong> the power<br />

company’s assessment and development activities<br />

and <strong>in</strong> the associated allocation <strong>of</strong> resources. <strong>STUK</strong><br />

required the Loviisa power plant to ensure that the<br />

procedures are appropriate and comply with the<br />

requirements. <strong>STUK</strong> will assess the situation <strong>in</strong><br />

the course <strong>of</strong> its <strong>oversight</strong> <strong>in</strong> 2012. <strong>STUK</strong> has found<br />

scope for improvement <strong>in</strong> the follow-up procedures<br />

<strong>of</strong> the Loviisa power plant regard<strong>in</strong>g the implementation<br />

and success <strong>of</strong> corrective actions decided follow<strong>in</strong>g<br />

plant’s own operational events.<br />

<strong>STUK</strong>-B 147<br />

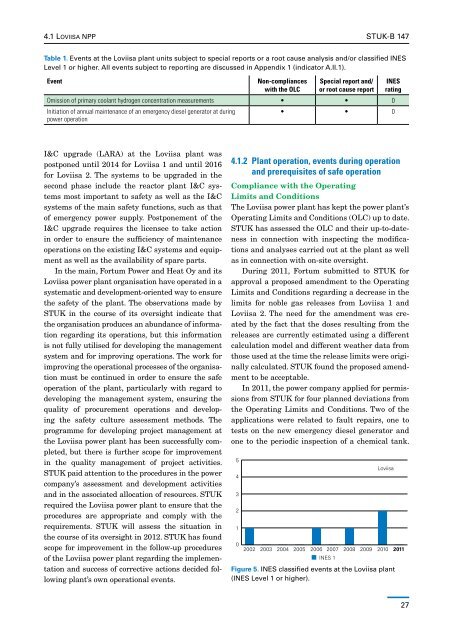

Table 1. Events at the Loviisa plant units subject to special reports or a root cause analysis and/or classified INES<br />

Level 1 or higher. All events subject to report<strong>in</strong>g are discussed <strong>in</strong> Appendix 1 (<strong>in</strong>dicator A.II.1).<br />

Event Non-compliances<br />

with the OLC<br />

Special report and/<br />

or root cause report<br />

Omission <strong>of</strong> primary coolant hydrogen concentration measurements • • 0<br />

Initiation <strong>of</strong> annual ma<strong>in</strong>tenance <strong>of</strong> an emergency diesel generator at dur<strong>in</strong>g<br />

power operation<br />

• • 0<br />

INES<br />

rat<strong>in</strong>g<br />

4.1.2 Plant operation, events dur<strong>in</strong>g operation<br />

and prerequisites <strong>of</strong> safe operation<br />

Compliance with the Operat<strong>in</strong>g<br />

Limits and Conditions<br />

The Loviisa power plant has kept the power plant’s<br />

Operat<strong>in</strong>g Limits and Conditions (OLC) up to date.<br />

<strong>STUK</strong> has assessed the OLC and their up-to-dateness<br />

<strong>in</strong> connection with <strong>in</strong>spect<strong>in</strong>g the modifications<br />

and analyses carried out at the plant as well<br />

as <strong>in</strong> connection with on-site <strong>oversight</strong>.<br />

Dur<strong>in</strong>g 2011, Fortum submitted to <strong>STUK</strong> for<br />

approval a proposed amendment to the Operat<strong>in</strong>g<br />

Limits and Conditions regard<strong>in</strong>g a decrease <strong>in</strong> the<br />

limits for noble gas releases from Loviisa 1 and<br />

Loviisa 2. The need for the amendment was created<br />

by the fact that the doses result<strong>in</strong>g from the<br />

releases are currently estimated us<strong>in</strong>g a different<br />

calculation model and different weather data from<br />

those used at the time the release limits were orig<strong>in</strong>ally<br />

calculated. <strong>STUK</strong> found the proposed amendment<br />

to be acceptable.<br />

In 2011, the power company applied for permissions<br />

from <strong>STUK</strong> for four planned deviations from<br />

the Operat<strong>in</strong>g Limits and Conditions. Two <strong>of</strong> the<br />

applications were related to fault repairs, one to<br />

tests on the new emergency diesel generator and<br />

one to the periodic <strong>in</strong>spection <strong>of</strong> a chemical tank.<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

2002 2003 2004 2005 2006 2007 2008 2009 2010 2011<br />

INES 1<br />

Loviisa<br />

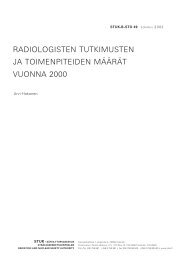

Figure 5. INES classified events at the Loviisa plant<br />

(INES Level 1 or higher).<br />

27