FLEISCHWIRTSCHAFT international 1/2017

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

...............................<br />

.......................................................<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

25<br />

Machinery<br />

nicalcharacteristics of the power<br />

grinder type Zh9-FIS.<br />

Afat separator for<br />

dehydration and degreasing<br />

Afundamentally newtypeof<br />

equipmentfor heat treatment of<br />

the groundsecondary meat raw<br />

materials of universal application<br />

is afat separator.Inthe developed<br />

technological process the dry heat<br />

treatment methodthateliminates<br />

thecontactofthe processed raw<br />

materials with the heat carrier<br />

(steam or hotwater) was used.<br />

This method of heatingisutilized<br />

with the aimtoeliminateorminimize<br />

the formation of broth containing<br />

soluble protein substances<br />

and emulsified fat. In some cases<br />

this brothbecomes the main<br />

component of industrial wastewater,whatcauses<br />

great environmental<br />

damage.<br />

Thefat separatortypeYa8-FLK-3<br />

is ascrew machine (Fig. 3). It<br />

consists of abodyprovided with a<br />

steam jacket.Inacut thebottom<br />

of thisismade in the shapeofa<br />

semicircle. Inside it,along the<br />

body on bearings, ahollow screw<br />

shaft is mounted, under the action<br />

of which the groundedraw material<br />

is moved to adischarge nozzle.<br />

Thescrew shaft is rotated counterclockwise<br />

from the side of the<br />

loading hopper.Steam with the<br />

pressure of 0.3 to 0.4 MPais<br />

supplied in the jacket andthe<br />

hollow screw shaft.From the<br />

outside the steam jacket is thermally<br />

insulated. To drain the juice<br />

steam, there is apipeonthe cover<br />

of the device, to which avent<br />

pipe-line is attached. Thescrew<br />

shaft is rotated by an individual<br />

electric motor through the V-belt<br />

transmission andawormgear<br />

located at the upper end ofthe<br />

shaft.<br />

Through thelower end steam is<br />

fed to the screw shaft,and condensateisdischarged.<br />

To the<br />

jacket thesteam is fedthrough a<br />

collector in the upperpart of the<br />

device, andthe condensateexits<br />

through anozzlelocated in the<br />

bottom. Aspecial feature of the<br />

device is the availability of perforation<br />

in the lower part of the<br />

body, through which themelted<br />

fat and coagulated moistureare<br />

removed fromit. To cleanthe<br />

perforation,acomb fixed to the<br />

rotating shaft in the bearings is<br />

available.Atthe end of the shaft<br />

there is alever with aroller interacting<br />

with the cylindrical cam,<br />

which is fixed to the screwshaft.<br />

Thecam has acutout in the shape<br />

of atriangle, thesmallcathetus of<br />

which is arrangedradially.Atthe<br />

end of the lever acounterweightis<br />

suspended.<br />

Thecleaning mechanism works<br />

as follows: During the rotation of<br />

the screw shaft,the cam mounted<br />

on it removesthe combwith the<br />

pins down, opening the perforation<br />

holes.When theroller<br />

reaches the cut-out in the cam, the<br />

counterweight sharply submits<br />

the comb up,the pins enterthe<br />

holes and clean them.<br />

As aresult of conductiveheating<br />

by the dry method, the fat<br />

contained in the raw material is<br />

melted and fl<br />

ows downintothe<br />

lower part of the device installed<br />

at an angle of 12 °tothe horizon.<br />

Duringprocessing the coagulation<br />

of raw meat proteins, which<br />

is accompanied by release of<br />

moisture, takes place. It is partly<br />

removed from the device through<br />

the perforation, aswellasby<br />

Tab. 1: Technical characteristics of the power grinder type<br />

Zh9-FISU<br />

Capacity, kg/h 2000<br />

Maximum size of loaded raw material, mm<br />

350x350x480<br />

Size of pieces after grinding, mm up to 50<br />

Cutter shaft rotational speed, s -1 0.7<br />

Electric motor power, kW 13<br />

Overall dimensions, mm<br />

Mass, kg 1293<br />

2065x1505x1085<br />

Source: FAIVISHEVSKY <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2017</strong><br />

Source: FAIVISHEVSKY <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2017</strong><br />

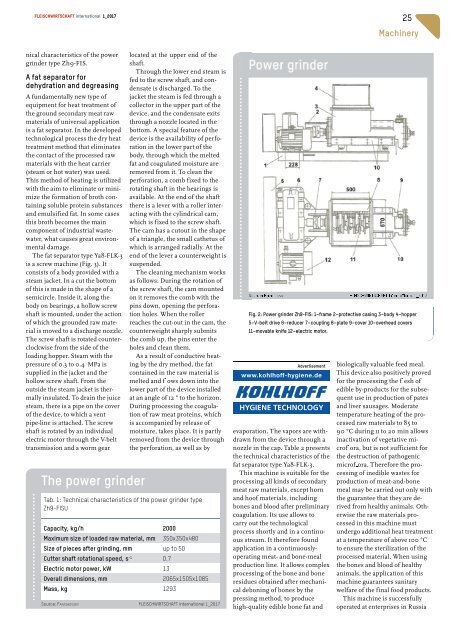

Fig. 2: Power grinder Zh9-FIS: 1–frame 2–protective casing 3–body 4–hopper<br />

5–V-belt drive 6–reducer 7–coupling 8–plate 9–cover 10–overhead covers<br />

11–movable knife 12–electric motor.<br />

Advertisement<br />

evaporation. Thevapors arewithdrawn<br />

from the devicethrough a<br />

nozzle inthe cap. Table 2presents<br />

the technical characteristics ofthe<br />

fatseparator typeYa8-FLK-3.<br />

This machineissuitable for the<br />

processing all kinds of secondary<br />

meat raw materials, except horn<br />

and hoof materials, including<br />

bones andblood after preliminary<br />

coagulation. Itsuse allows to<br />

carry out thetechnological<br />

process shortly and in acontinuous<br />

stream. It therefore found<br />

application inacontinuouslyoperating<br />

meat- andbone-meal<br />

production line. It allows complex<br />

processing of the bone andbone<br />

residues obtained aftermechanical<br />

deboningofbones by the<br />

pressingmethod, to produce<br />

high-quality edible bone fat and<br />

biologically valuable feed meal.<br />

This device alsopositively proved<br />

for the processing the fl<br />

esh of<br />

edible by-products for thesubsequent<br />

useinproduction of pates<br />

and liver sausages. Moderate<br />

temperature heating of the processed<br />

rawmaterials to 85 to<br />

90 °C during 11 to 20 min allows<br />

inactivation of vegetative microfl<br />

ora, butisnot sufficientfor<br />

the destruction of pathogenic<br />

microfl<br />

ora. Therefore the processing<br />

of inedible wastes for<br />

production of meat-and-bone<br />

meal may be carriedout only with<br />

the guaranteethat theyare derived<br />

from healthy animals. Otherwise<br />

the rawmaterials processed<br />

inthis machine must<br />

undergo additional heat treatment<br />

at atemperature of above 100 °C<br />

to ensurethe sterilization of the<br />

processed material. When using<br />

the bones and blood of healthy<br />

animals, the application of this<br />

machine guarantees sanitary<br />

welfare of the final food products.<br />

This machineissuccessfully<br />

operated at enterprisesinRussia