FLEISCHWIRTSCHAFT international 1/2017

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

.........................................<br />

Fleischwirtschaft <strong>international</strong> 1_<strong>2017</strong><br />

63<br />

Research &Development<br />

D-value; pH’ is the pH of the recovery medium; pH’opt is the optimal pH value<br />

of the recovery medium; z’pH is the distance of pH from pH’ of the recovery<br />

medium which leads to aten-fold reduction of the D-value; a’w is aw of the<br />

recovery medium; a’wopt is the optimal aw of the recovery medium; z’aw is the<br />

distance of aw from the a’w of the recovery medium which leads to atenfold<br />

reduction of the D-value.<br />

Taking into consideration the correlation between the time of decimal<br />

reduction and the degree of lethality L:<br />

D=<br />

D*<br />

L<br />

anew calculation model of the Lvalue was elaborated:<br />

T–T* IpH–pH*I a w–1<br />

a´w–1<br />

pH´–pH´opt<br />

( ) 2<br />

z´aw<br />

L =10<br />

( ) 2<br />

z T z pH z aw z´pH<br />

+ + ++<br />

Explanations as in the equation above.<br />

It replaces the well-known model elaborated by BIGELOW (1921).<br />

The application of the above-presented model requires the determination<br />

of appropriate coefficients (zpH,zaw,z’pH,z’aw)for the indicator microorganism.<br />

These coefficients were determined for bacteria from the<br />

Bacillus and Clostridium genera, in other words, sporulating bacteria<br />

which should be taken into consideration during the sterilisation process<br />

(LEGUÉRINEL et al., 2000, 2005; GAILLARD et al., 1998; COROLLER,etal., 2001;<br />

MAFART et al., 2001).Following the process of sterilisation of canned meat<br />

products of the SSP type, spores of bacteria are no longer capable of<br />

germinating because of unfavorable environmental conditions (reduced<br />

aw and pH values, presence of NaNO2)and, therefore, when assessing the<br />

effectiveness of the heating process, it is necessary to take into account<br />

the survivability of thermoresistant non-sporulating bacteria. Enterococci<br />

are considered to be most thermoresistant among the vegetative bacteria<br />

(GIRAFFA,2002; FRANZ et al., 2003; HUGAS et al., 2003). These bacteria<br />

occur in many foods (meat, dairy and vegetable origin) and play an important<br />

role in the production of fermented meat products and cheese (PAVIA<br />

et al., 2000). The surface of pig carcasses contain 10 4 to 10 8 enterococci<br />

per 100cm 2 .The predominant isolated species are E. faecium and E.<br />

faecalis (KNUDTSON and HARTMAN,1993). Enterococci are used as starter<br />

cultures and their bacteriocins are usuallyactive towards such<br />

pathogens like Listeria and Clostridium (GIRAFF et al., 1995, 1997; AYMERICH<br />

et al., 2000). They are also used as human probiotics however they are<br />

important nosocomial pathogens, that cause bacteraemia, endocarditis<br />

and other infections. The role of enterococci in diseases call into question<br />

their safety for the usage in foods or as probiotics. The presence of<br />

enterococci in the gastrointestinal tract of animals leads to ahigh potential<br />

for contamination of meat at the time of slaughter (FRANZ et al., 2003).<br />

In the case of these microorganisms, the impact of water activity on<br />

changes in their thermoresistance and possibilities of regeneration after<br />

pasteurisation was determined, in other words, zaw and z’aw values were<br />

determined which –for Enterococcus faecium PCM 1859 –amount to 0.14<br />

and 0.44, respectively(DANYLUK et al., 2013). On the other hand, no information<br />

is available with respect to the influence of pH on the behavior of<br />

these microorganisms during pasteurization and their possibilities of<br />

regeneration during astorage period, i.e. zpH and z’pH values were not<br />

determined.<br />

The aim of this paper was to ascertain thermoresistance and regeneration<br />

possibilities of thermallydamaged Enterococcus faecium PCM 1859<br />

cells depending on the pH value of the medium during heating and incubation<br />

following the thermal process and to determine zpH and z’pH values. In<br />

combination with the results published earlier (DANYLUK et al., 2013), they<br />

allow the determination of anew formula for the calculation of the degree<br />

of lethality which constitutes the basis for the determination of the pasteurization<br />

value Pduring heating of canned meat products. The subjectmatter<br />

of the article is very complex and depends on anumber of factors<br />

mentioned in the manuscript and it constitutes amodel system which<br />

provides abasis for further investigations in future.<br />

Materials and methods<br />

Preparation of samples<br />

The bacterial strain used in the described experiments was that of Enterococcus<br />

faecium PCM 1859 derived from the Strain Collection of the Polish<br />

Academy of Sciences in Wrocław. Experimental bacteria were cultured on<br />

Slanetzand Bartey medium with differing pH values. The substrate pH value<br />

was reduced with by HCl and the following variants were obtained:<br />

r basic medium (optimal) containing: pepton 20.0 g, dipotassium phosphate<br />

4.0 g, yeast extract 5.0 g, glucose 2.0 g, sodium azide 0.4 g,<br />

TTC0.1 g, agar 15.0 g, distilled water 1L;pHofthe ready medium 7.2,<br />

aw=1.0 –A<br />

r basic medium +0.8 mL 1NHCl; aw=1.0, pH= 7.0–B<br />

r basic medium +2.7 mL 1NHCl; aw=1.0, pH= 6.8 –C<br />

r basic medium +5.0 mL 1NHCl; aw=1.0, pH= 6.5 –D<br />

Following inoculation, the samples were incubated for 48 hatatemperature<br />

of 37 °C. Bacteria collected from media AtoDwere placed in the test<br />

tubes (Ø= 16 mm) with aphysiological fluid containing the same quantity of<br />

HCl as during culturing. Their initial concentration amounted to 10 6 to<br />

10 8 cfu/mL. Next, 10 mL suspension was collected from each flask, transferred<br />

to three test tubes and heated in awater bath at atemperature of<br />

55 °C, respectively, for 10,20and 30 min. The same procedures were followed<br />

when bacteria were heated at atemperature of 60 °C for 1, 3and<br />

5min and at 65 °C for 1, 2and 3min. Each experiment was repeated three<br />

times. After the appropriate time of heating, the bacteria were inoculated<br />

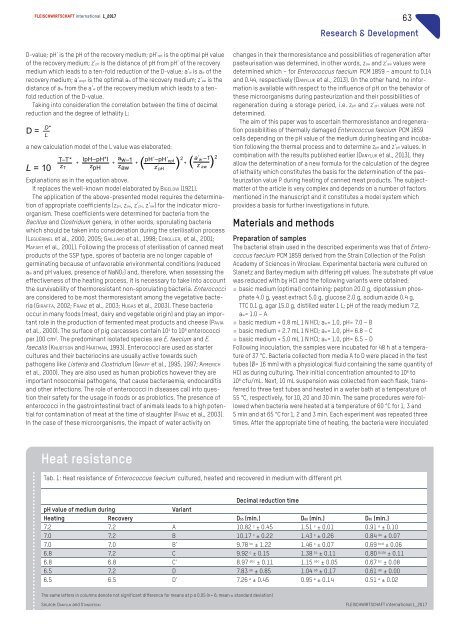

Heat resistance<br />

Tab. 1: Heat resistance of Enterococcus faecium cultured, heated and recovered in medium with different pH.<br />

Decimal reduction time<br />

pH value of medium during<br />

Variant<br />

Heating Recovery D55 (min.) D60 (min.) D65 (min.)<br />

7.2 7.2 A 10.82 c ±0.45 1.51 c ±0.01 0.91 e ±0.10<br />

7.0 7.2 B 10.17 c ±0.22 1.43 c ±0.26 0.84 de ±0.07<br />

7.0 7.0 B’ 9.78 bc ±1.22 1.46 c ±0.07 0.69 bcd ±0.06<br />

6.8 7.2 C 9.92 c ±0.15 1.38 bc ±0.11 0,80 bcde ±0.11<br />

6.8 6.8 C’ 8.97 abc ±0.11 1.15 abc ±0.05 0.67 bc ±0.08<br />

6.5 7.2 D 7.83 ab ±0.85 1.04 ab ±0.17 0.61 ab ±0.00<br />

6.5 6.5 D’ 7.26 a ±0.45 0.95 a ±0.14 0.51 a ±0.02<br />

The same letters in columns denote not significant difference for means at p ≤ 0.05 (n= 6; mean ±standard deviation)<br />

Source: DANYLUK and STANGIERSKI <strong>FLEISCHWIRTSCHAFT</strong> <strong>international</strong> 1_<strong>2017</strong>